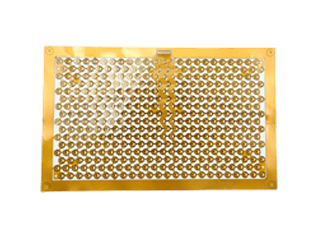

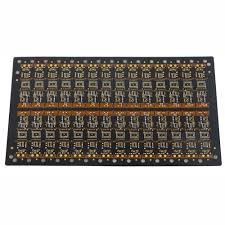

WellCircuits specializes in producing high-precision and complex flex PCBs that include multilayer flex PCBs and ultra long flex PCBs along with 90° degree bending flexible circuits. The company specializes in manufacturing flex PCBs that range from 1 to 32 layers within China.

Flex PCB

Flexible PCBs consist of flexible substrates that are both extremely thin and lightweight while rigid-flex PCBs integrate rigid and flexible technologies to enhance versatility and mobility. Flex PCBs offer many benefits and advantages compared to rigid PCBs and traditional rigid PCBs, including superior flexibility, lightweight construction, and design versatility. These advantages make flex PCBs ideal for applications where space-saving, dynamic bending, and complex geometries are required. This section provides additional details about flexible technology compared to rigid technology and addresses some commonly asked questions (FAQs). Read further if interested in the latest PCB design trends.

The substrate of flexible PCBs combines exceptional bendability with high tensile strength and physical flexibility, which allows these boards to be shaped into complex three-dimensional forms for application in multiple industries. In flex circuit construction, different materials such as various base films and polymer films—including polyimide and polyester—are used. Polymer film serves as the flexible substrate material and acts as the base layer, providing essential physical and electrical properties for various types of flex PCB designs, including polymer thick film circuits and single-sided flexible circuits. The choice of base film directly affects the electrical, mechanical, chemical, and thermal performance of the flexible circuit board. Initially developed for military applications because of their durability and lightweight nature, flexible boards have since gained popularity across multiple fields, including medical devices, fitness wearables, cameras, and as replacements for wiring harnesses or ribbon connectors.

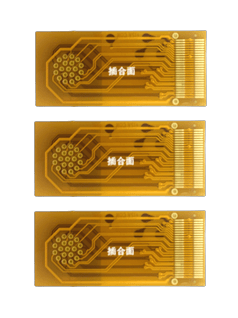

Flexible circuits fall under three main categories, which include single layer (single-sided) boards, double sided flex (double sided flex PCB), and multi-layered boards. The term sided flex PCB can refer to both single and double-sided designs.

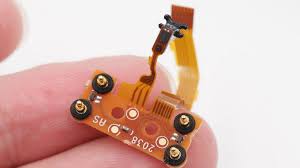

The construction of single-sided flexible circuit boards represents the most basic method among flexible board types. A single conductor layer on a flexible substrate forms its construction, which is sandwiched by a flexible polyimide layer and a fine copper sheet, while holes in the surface enable component leads to pass during soldering processes, and coverlays made from polyimide act as a protective layer to shield against environmental elements and electromagnetic interference that may compromise circuit performance.

The construction of double-sided flexible circuit boards involves bonding two conductor layers to both sides of a polyamide flexible substrate. This double sided flex or double sided flex PCB structure allows for trace patterns on both sides, facilitating more complex connections and increased functionality compared to single-sided designs. Copper foil is bonded to both sides through adhesive application, while plated holes or vias (through holes) create electrical connections between layers, and protection layers are added to one side, both sides, or none, depending on circuit design demands.

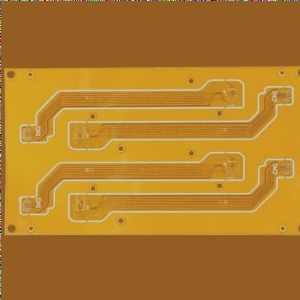

Multi-layered flex circuits, also known as multilayer flex circuits, consist of more than two conductor layers made of copper wire connected by vias or PTHs (through holes)—much like double-sided boards—providing an efficient means of solving design challenges related to specific impedance specifications, crossings that cannot be avoided and crosstalks, component density, and shielding. Through holes are essential for connecting conductor layers, enhancing design complexity and electrical connectivity.

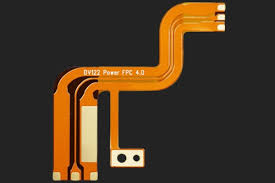

FFC (flexible flat cables) is a type of cable electrically flexible and flat, whereas an FPC is a flexible and printed circuit. Flexible circuit boards are a key component of flexible electronics, enabling the mounting of electronic components such as integrated circuits, resistors, and capacitors on flexible substrates. FFC is a form of ribbon cable, and it is named in honor of its wide and flat design. These are typically straight connectors used in PCB layout that do not have any other components. FFC cables typically consist of a film made of plastic with multiple connectors made of metal are attached. The distance between them is known as”pitch”.

In demanding environments such as aerospace, automotive, and medical devices, high reliability is a key advantage of flexible PCBs, as they maintain performance under vibration, shock, and thermal stress.

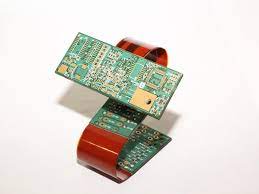

When integrating flex and rigid technologies, options include rigid boards, flex and rigid combinations, rigid flex board, and rigid flex circuits. Rigid flex circuits combine rigid and flexible substrates into a single laminated structure, offering unique design and assembly advantages for complex electronic assemblies.

While rigid PCBs and traditional rigid PCBs remain widely used for applications requiring high-power handling and mechanical stability, flexible circuit boards provide unique advantages in terms of flexibility, weight, and design freedom.

Introduction to Flexible Circuits

Flexible circuits, often referred to as flex circuits, represent a transformative advancement in printed circuit board (PCB) technology. Unlike traditional rigid boards, flexible circuits are constructed on a flexible substrate, allowing them to bend, fold, and twist to fit into compact or irregularly shaped spaces without compromising performance. This flexibility is achieved through a multi-layered structure, typically consisting of a conductive layer—most commonly copper—sandwiched between a flexible dielectric layer such as polyimide or polyester, and a protective layer that shields the circuit from moisture, dust, and extreme temperatures.

The unique construction of flexible circuits enables the integration of complex electronic pathways within a lightweight and durable format. The protective layer not only guards against environmental hazards but also enhances the longevity and reliability of the circuit, making it ideal for use in demanding applications. Flexible circuits are widely used in medical devices, where their ability to conform to small, intricate spaces is crucial, as well as in consumer electronics, where space constraints and lightweight designs are paramount. By leveraging the inherent advantages of flexible substrates and advanced layering techniques, flex circuits have become a cornerstone of modern electronic design, supporting innovation across a diverse range of industries.

Applications

The versatility of flexible circuits has led to their widespread adoption across numerous industries, where their unique properties deliver significant benefits. In consumer electronics, flexible circuits are found in smartphones, tablets, laptops, and wearable devices, enabling sleek, compact designs and reliable connections between densely packed components. Their ability to bend and flex without breaking makes them essential for devices that require frequent movement or folding.

In the medical field, flexible circuits are integral to the development of advanced medical devices such as pacemakers, implantable cardioverter-defibrillators, and portable monitoring equipment. Their lightweight and adaptable nature allows for minimally invasive designs and enhances patient comfort, while maintaining the high reliability required for life-critical applications.

Aerospace and defense sectors also rely heavily on flexible circuits for satellites, spacecraft, and aircraft systems, where weight reduction, durability, and the ability to withstand vibration and thermal cycling are critical. Additionally, flexible circuits are used in industrial automation, robotics, and control systems, where they provide robust and efficient connections in environments that demand both flexibility and reliability.

By enabling reduced size and weight, improving reliability, and offering unparalleled design flexibility, flexible circuits continue to drive innovation in electronic products and systems across the globe.

Design Considerations

Designing flexible printed circuit boards (flex PCBs) requires a strategic approach that balances electrical performance, mechanical durability, and manufacturability. Unlike traditional rigid boards, flexible circuits must endure repeated bending, twisting, and folding, all while maintaining reliable electrical connections and meeting the stringent requirements of modern electronic devices.

A critical first step in flex PCB design is the careful selection of the base material. Polyimide films are widely favored for their advantageous electrical, mechanical, and thermal properties, making them the backbone of most flexible printed circuit boards. These materials provide the flexibility needed for dynamic applications while ensuring the circuit can withstand high temperatures and harsh environments, which is especially important in medical devices and aerospace systems.

The design of the conductive layer is equally important. Copper foil is the standard choice due to its excellent conductivity and flexibility. The thickness of the copper layer must be optimized: too thick, and the circuit loses flexibility; too thin, and it may not handle the required current or mechanical stress. For multilayer flex circuits, careful planning of conductor routing and via placement is essential to maintain signal integrity and reliable electrical connections across all layers.

Protective layers, such as polyimide coverlays or flexible solder masks, are applied to shield the conductive traces from moisture, dust, and mechanical abrasion. These layers not only enhance reliability but also help prevent electromagnetic interference (EMI), which can be more pronounced in flexible circuits due to their thin profiles and close proximity to other electronic components.

Space constraints are a defining factor in flex PCB design, particularly in consumer electronics and medical devices where every millimeter counts. Designers must optimize circuit layouts to maximize functionality within minimal space, often employing advanced flex PCB design techniques to route traces efficiently and avoid unnecessary complexity. The assembly process for flexible PCBs can also be more intricate than for rigid boards, requiring specialized equipment and handling procedures to prevent damage during component placement and soldering.

Thermal management is another key consideration. Flexible PCBs, by nature of their thin and lightweight construction, can be more susceptible to heat buildup. Incorporating thermal vias, heat spreaders, or selecting base materials with superior thermal properties can help dissipate heat and maintain optimal performance, even in demanding applications.

Electromagnetic interference is a potential challenge in flex circuit construction, as the flexible sections can act as antennas if not properly shielded. Employing ground planes, shielding layers, or strategic trace placement can mitigate EMI and ensure signal integrity, which is vital for high-speed or sensitive electronic devices.

Component selection must also align with the flexible nature of the circuit. Surface-mount technology (SMT) components are typically preferred, as they are lightweight and can better withstand the mechanical stresses of flexing. The assembly process should be tailored to accommodate the unique handling requirements of flexible PCBs, ensuring that components remain securely attached throughout the product’s lifecycle.

Different types of flex PCBs—whether single layer, double sided flex, or multilayer flex circuits—each present unique design challenges. For example, double sided flex PCBs require precise via design to ensure robust electrical connections between layers, while multilayer designs demand careful management of layer stacking and interconnections to avoid signal loss or crosstalk.

Ultimately, successful flex PCB design hinges on a holistic understanding of materials, electrical requirements, mechanical stresses, and assembly processes. By addressing these considerations from the outset, engineers can create flexible printed circuits that deliver high reliability, superior performance, and the space-saving advantages demanded by today’s advanced electronic products. For applications requiring even greater versatility and durability, rigid flex PCBs offer a compelling solution by combining the strengths of both rigid and flexible technologies in a single, integrated design.

Reliability

Reliability is a defining characteristic of flexible circuits, making them the preferred choice for applications where consistent performance is non-negotiable. Engineered to endure a wide range of environmental stresses—including extreme temperatures, vibration, and moisture—flexible circuits are manufactured using high-quality materials and advanced fabrication techniques that ensure long-term durability.

The robust design of flexible circuits allows them to maintain electrical integrity even in harsh environments, such as those encountered in aerospace, automotive, and industrial settings. Their construction minimizes the risk of mechanical failure, as the flexible substrate absorbs shocks and vibrations that could otherwise damage traditional rigid boards. Furthermore, the manufacturing process for flexible circuits incorporates rigorous testing and inspection protocols, enabling early detection and correction of defects to enhance overall product reliability.

By providing a dependable means of connecting electronic components in challenging conditions, flexible circuits help OEMs and engineers achieve high reliability in their end products. This reliability, combined with their adaptability and performance, continues to expand the use of flexible circuits in mission-critical applications where failure is not an option.

Flexible Circuit Base Material

The base material forms the backbone of flexible printed circuit boards, playing a pivotal role in determining their flexibility, durability, and electrical performance. In flexible circuits, the choice of base material directly influences how well the board can withstand repeated bending, thermal cycling, and the rigors of assembly, making it a key consideration for engineers designing advanced electronic devices.

Polyimide films, such as Kapton, are the most prevalent owing to their exceptional high temperature resistance, chemical stability, and ability to retain advantageous electrical properties across a broad temperature range. These flexible polyimide substrates are lightweight and can be manufactured in extremely thin layers, which is essential for applications where space savings and lightweight designs are critical—such as in medical devices, consumer electronics, and aerospace systems. The polyimide base material is typically laminated with a conductive layer, most commonly copper foil, to form the circuit paths that carry electrical signals throughout the flexible printed circuit board.

Polyethylene naphthalate (PEN) is another popular base material, valued for its good mechanical stability and cost-effectiveness. While not as heat-resistant as polyimide, PEN offers sufficient thermal properties for many standard applications and is often chosen when budget constraints are a priority.

Other materials, such as polyester (PET) and fluoropolymers (FEP), are also used in specific scenarios. PET provides a balance of flexibility and electrical performance at a lower cost, making it suitable for high-volume, cost-sensitive products. FEP, on the other hand, is selected for its outstanding chemical resistance and ability to perform in harsh environments where exposure to aggressive chemicals or extreme temperatures is expected.

The selection of base material impacts not only the mechanical and thermal properties of the flexible printed circuit board but also factors such as assembly process, lead time, and overall cost. For example, high-performance polyimide films may increase material costs but enhance reliability and lifespan in demanding applications, while PET may be preferred for simpler, disposable electronic products.

Ultimately, the base material is a critical factor in flex PCB design, influencing everything from the board’s thickness and flexibility to its ability to handle heat dissipation and maintain signal integrity. By carefully matching the base material to the specific requirements of the application, engineers can ensure that their flexible printed circuits deliver optimal performance, reliability, and value.