Addressing Short Circuits and Micro Shorts on PCB Circuit Boards

Short circuits and micro shorts are common issues on PCB circuit boards, but there are effective methods to resolve them. Here’s a detailed explanation:

Testing Challenges

Finished boards with micro shorts or short circuits may not be detectable using standard low-voltage testers to avoid customer complaints. High-voltage testing machines are developed to address this issue, but even with these machines, a 100% pass rate is not always guaranteed.

Identifying Short Circuits

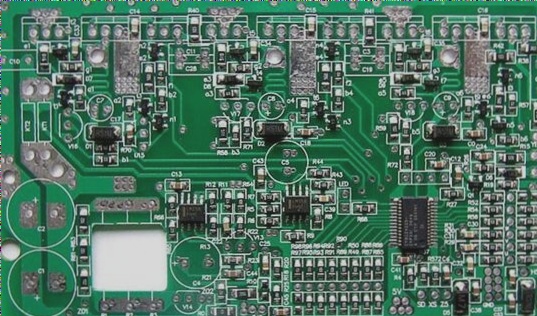

Some boards may pass low-voltage tests but fail high-voltage tests, indicating a short circuit. Using a multimeter to measure resistance can confirm a complete short circuit. Examination with a magnifying glass may reveal the cause, such as solder mask ink.

Solution: Board Grinding Machine

An effective solution is to use a plate grinding machine for edge treatment. This process involves grinding, bridging wires, and applying green oil to prevent short circuits. Implementing swing brushing and high-pressure washing can further enhance the board’s quality.

Preventing Short Circuits

WellCircuits Limited specializes in manufacturing high-precision circuit boards, including HDI, thick copper, backplanes, and rigid-flex assemblies. These boards are designed to minimize the occurrence of short circuits and meet diverse customer needs.