PCB Panelization and Depanelization Techniques

PCB panelization is a manufacturing method that involves arranging multiple PCBs on a single larger panel. This technique streamlines the PCB assembly process and is commonly used to enhance efficiency, especially for small or irregularly shaped PCBs.

Benefits of PCB Panelization:

- Facilitates movement through assembly line

- Allows for different board designs on the same panel

- Eases separation of individual boards post-manufacturing

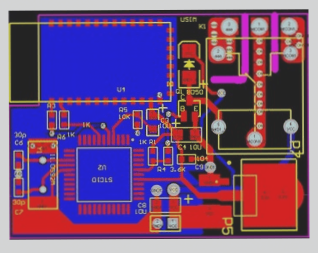

Figure 1: PCB Panelization

Depanelization Techniques

Depanelization is the process of separating individual circuit boards from a panel after manufacturing. Two common depanelization methods are V-Scoring and Tab Routing.

V-Scoring Method

V-scoring involves cutting V-shaped grooves into the panel to separate the boards. While effective for straight-line cuts, V-scoring may not be suitable for irregular shapes or boards with components extending over the edges.

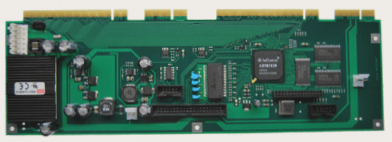

Figure 2: V-Scoring

Tab Routing Method

Tab routing involves creating tabs along the board edges for separation. This method is versatile, accommodating irregular shapes and components extending beyond the board edges. Perforations on tabs aid in clean separation post-assembly.

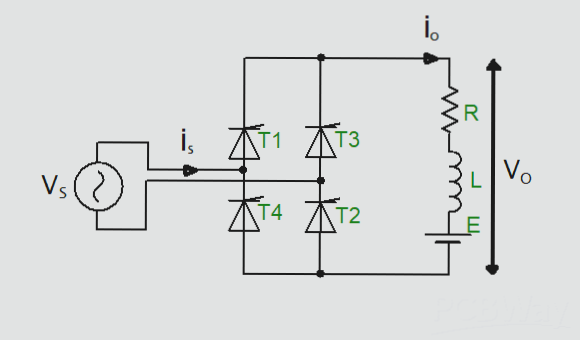

Figure 3: Tab Routing

Enhancements:

- Perforations for easier separation

- Breakaway rails for added support

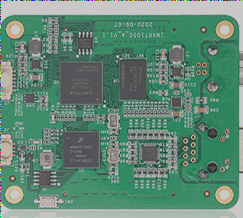

Figure 4: Breakaway Rails

If you have any queries about PCBs or PCBA, reach out to us at info@wellcircuits.com.