Have you ever wondered what an LED Aluminum PCB is? Or maybe you’ve heard about them and were too curious to ignore. Perhaps you want to know what makes these boards so remarkable that even the sites that sell them can’t stop themselves from going on and on about how great they are.

Maybe you’re just bored. Those things sounded like a good idea, so here we are. So you’re going to buy an aluminum PCB for your next board?

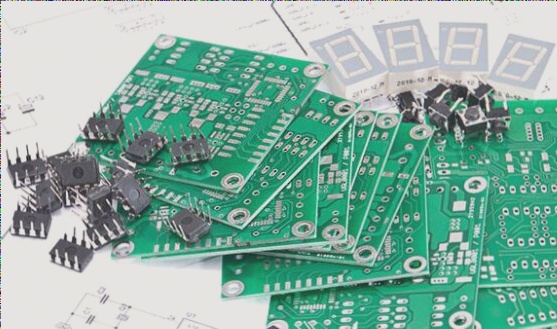

Aluminum is an excellent choice as it can be layered just like a wood base layer on top of a regular PCB (or FR-4 material) and provides an ideal base for the soldered components.

These boards are of high quality and can be used in any project. There are other options for the base materials, but aluminum is considered one of the best choices due to its unique properties that allow for large surface mount footprints and wide traces, which will work well with many SMD LEDs and through-hole (non-SMD) components.

What Is An LED Aluminium PCB?

An LED aluminum PCB is a printed circuit board consisting of an aluminum core with or without copper foil laminated on both sides of the aluminum.

The heat generated by high-power LEDs during operation can be dissipated much faster by this kind of board, which dramatically increases the life span of the LEDs.

In addition, since aluminum has higher thermal conductivity than FR-4 and CEM-3, the size of an LED aluminum PCB can be smaller than that of a regular PCB with the same components populated.

These are printed circuit boards (PCBs) designed explicitly for connecting LEDs. As you know, it is the most crucial part of LED lighting. Since PCBs have been used for years, we may feel indifferent about them. But don’t be so quick to judge this simple part before knowing more about it.

Nowadays, LED lights are becoming more and more popular because they are more energy-efficient than traditional ones.

This can significantly reduce our electricity bills and carbon footprint and is gaining lots of attention from industries and governments worldwide.

What Are The Types Of The LED PCBs?

There are two types of LED PCBs: Single-sided and double-sided boards.

- Single-Sided Boards

Single-sided boards are cheaper but do not offer as much flexibility when designing your circuit layout. You cannot use both sides of the board for mounting components like resistors or capacitors.

- Double-Sided Boards

Double-sided boards cost more initially but allow for greater flexibility in design because components can be placed on either side of the board without any issues with heat dissipation or electrical noise interference between layers.

Why Should One Buy LED PCBs?

There are many reasons you would want to use LEDs on your PCBs.

- One reason is that they give off more light than incandescent bulbs and fluorescent tubes, meaning you can use more of them without worrying about overheating your electrical equipment.

- Another reason is that they’re easier on your eyes because they don’t produce any glare as incandescent bulbs do.

- Finally, they’re more energy-efficient than other lighting sources because they use less power to produce more light which saves money!

What are the PCB LED Applications?

The LED lights are used in the panels designed for the PCB. The developed technology has enhanced the usage of these lights in a wide range of applications. These applications have led to a change in the lighting system of the world and will continue to do so.

- Street Lamps:

The most common application for LED lights is street lamps or traffic signals, where brightness levels vary greatly depending on weather conditions or time of day.

For example, during heavy rainstorms, it may be necessary for drivers to slow down because conventional lamps do not provide enough light to use LED lamps.

- Mobile Phones

The small circuit boards in your mobile phone use PCB LEDs to illuminate many different parts of the device.

These LEDs can be found on either side of the keypad to illuminate the keys when needed. They can also be seen adorning the screen for better visibility.

- Computers

PCB LEDs can be used to illuminate the keyboard on laptops and computers. It is becoming more common for these lights to be used instead of backlighting because they are smaller and do not require as much space as a bulb. They also last longer than backlighting and require less electricity to run.

- Lightings:

LED lighting is used in some unique lamps, such as ceiling lamps or wall lamps, which can be made into various colors and shapes to meet people’s individual needs, especially for high-end hotels, bars, and unique shops.

- Industry Lights:

Industrial lighting lamps are mainly used for indoor and outdoor lighting. The outdoor lights can be installed on the top of the building or along the street to attract people’s attention. Industrial lighting is widely used in various industries.

LED high bay lights are often used in factories with a height of 4-10 meters, and LED floodlights are often used in outdoor playgrounds and road lighting. Indoor lamps are often used in high-end electrical equipment production plants.

- Automobile Lighting:

Automobile lighting is also one application of LED lights, which is usually equipped with some auxiliary lights that use LED chips, such as car fog lights, headlamps, chassis lights, etc., making driving safer at night.

In addition, many automobiles have been equipped with traffic indicators on the outside mirror of the car body to reduce accidents caused by improper operation of the driver or other pedestrians who walk around the car.

- Traffic Lights

Traffic lights can indicate the direction of vehicles and tell pedestrians to cross the road safely. In the past, incandescent lamps were used for traffic lights.

However, because incandescent lamps have poor shock resistance and a short life span, they are prone to burnout during operation. Therefore, LEDs are widely used in traffic lights at present.

- Medical Treatment Apparatus

LEDs can be used in all aspects of medical treatment apparatus, including lamp panels and indicators. Examples are laser therapy machine light sources, color-coded hemostatic probes, ophthalmic instruments, endoscopic light sources, laparoscopy light sources, otoscopy illumination, etc.

Compared with traditional lamps, LEDs have the advantages of long service life and good shock resistance, ensuring that they are not damaged during use in medical equipment due to bumps or falls.

- Household Appliances:

LED is also widely used in household appliances. For example, TV screens, mobile phones, calculators, and others have all begun to use LED backlight sources or display screens.

What are the Features of LED PCB?

LED PCB circuit board can be divided into two categories: the LED display screen, which is mainly used in outdoor large-screen display systems and indoor advertising media; the other is LED lights PCB circuit board, which is primarily used in various kinds of lighting products.

Generally speaking, the main features of an LED PCB circuit board are as follows:

Smaller Volume:

The volume and weight of LED circuit boards are smaller than those of traditional incandescent lamp circuit boards or fluorescent lamp circuit boards.

High Power Density:

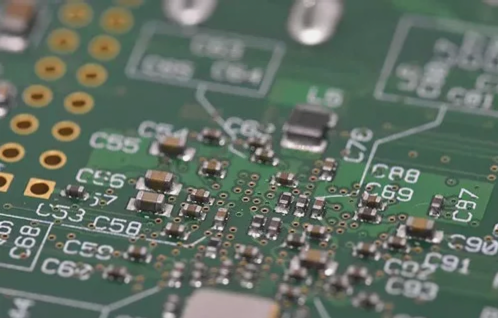

The power density of a single module or device can reach 10W/cm2 – 100W/cm2, which is several orders higher than that of standard electronic components. Therefore, it needs to consider the problem of heat dissipation in the design process.

High Pressure:

The forward voltage drop of different colors of LEDs is different from each other and changes with temperature characteristics, generally between 1V and 4V (blue light 3V to 4V).

High-Speed Transmission Technology

As the increase in electronic product functions gradually increases the data transmission rate between circuits, it has also put forward higher requirements on PCB circuit boards. Therefore, high-speed transmission technology is one of the critical technologies for PCB circuit boards.

High-Frequency Circuit Technology

High-frequency circuits refer to circuits with operating frequencies above 1MHz. With the development of communication and radar systems in recent years, the application frequency range of electronics has expanded from a few MHz to hundreds or even thousands of MHz.

Moreover, high-frequency circuit technology has become an important research topic in microwave integrated circuits fields.

The Heat-Conducting Performance Is Good

The LED PCB board has an excellent heat-conducting performance, so it can ensure the long-term stable operation of the chip and will not cause the circuit to be damaged due to overheating.

Good Insulation Performance

The LED PCB board has excellent insulation performance, effectively preventing the circuit’s leakage or short circuit and damaging the chip.

The Thickness Is Thin

The thickness of the LED PCB board is skinny, which significantly reduces the volume of the whole product and makes it more convenient for users to carry and use. At the same time, this can also make the product more beautiful when used.

Stable Performance

The LED PCB board has stable performance, so it will not cause any damage to the entire product during use, and it does not need to be repaired frequently. At the same time, it can also ensure that the product can generally work under harsh conditions and in an extreme environment.

Good Resistance to Chemical Corrosion

The LED PCB board has a strong resistance to chemical corrosion, so it has better durability than other circuit boards when used in harsh or terrible environments such as high temperature or high humidity.

Bottom Line:

Due to their aluminum base, LED aluminum PCBs conduct more heat and dissipate it faster than any other type of PCB. No other PCB works as well at managing heat in LED backlighting units. Despite this substantial advantage, LED aluminum PCBs are still a little rare in the market because they are relatively new.

Products made with these PCBs might be more expensive and less common than those on traditional PCBs. Still, if you are looking for the best possible product or want to add higher overall value to your product, an LED aluminum PCB is likely worth every penny.

wellcircuits is a China-based manufacturer of printed circuit boards operating for many years. We offer a broad range of printed circuit board (PCB) fabrication services to meet diverse customer requirements, including standard PCBs up to 28 layers, HDI PCBs, Flexible PCBs, and Rigid-Flex PCBs.

As a professional PCB manufacturer with over 10 years of experience in this industry, wellcircuits has had many experiences working with customers from North America, Australia, Europe, and the Middle East.