Essential PCB Manufacturing Equipment Used by Professional Electronics Manufacturers

The Evolution of PCB Manufacturing Technology

The printed circuit board (PCB) industry has undergone remarkable technological transformation, enabling modern high-density interconnect (HDI) boards and multilayer PCB solutions. Leading PCB manufacturers in China now utilize advanced equipment that combines precision engineering with automated processes to meet global demand for high-quality circuit boards.

Core Equipment in Professional PCB Fabrication

1. Schematic Design Systems

Professional PCB fabrication services begin with sophisticated electronic design automation (EDA) software running on high-performance workstations. These systems enable:

- Circuit simulation and verification

- Multi-layer board planning

- Design for manufacturability (DFM) analysis

Many international PCB suppliers offer design-to-production services, handling everything from schematic capture to final assembly.

2. Precision Imaging Equipment

Modern PCB production lines use:

- Laser direct imaging (LDI) systems

- UV exposure units

- Automated photoresist application machines

This equipment ensures micron-level accuracy when transferring circuit patterns to copper-clad laminates.

3. Advanced Etching and Stripping Systems

State-of-the-art facilities utilize:

- Automated alkaline etching lines

- Closed-loop chemical management systems

- Precision stripping machines

These systems maintain consistent trace width control while meeting environmental compliance standards for PCB export businesses.

Specialized PCB Processing Equipment

4. Solder Mask Application Systems

Professional PCB manufacturers employ:

- Curtain coating machines

- UV-curable solder mask printers

- Automated inspection systems

This ensures proper insulation and protection of copper traces while maintaining precise opening accuracy for component pads.

5. Surface Finish Treatment Equipment

For export-quality PCBs, manufacturers use:

- Electroless nickel immersion gold (ENIG) lines

- Organic solderability preservative (OSP) systems

- Immersion silver treatment equipment

These processes enhance solderability and protect against oxidation during international shipping.

6. Multilayer Lamination Presses

High-volume PCB factories utilize:

- Hydraulic lamination presses

- Vacuum bonding systems

- Automated prepreg handling

This equipment enables production of complex multilayer boards with perfect layer alignment.

7. CNC Routing and Drilling Systems

Modern PCB manufacturing equipment includes:

- Laser drilling machines

- High-speed mechanical drills

- Automated routing systems

These ensure precision hole placement and clean board outlines for high-mix production environments.

PCB Assembly and Testing Equipment

8. Solder Paste Printing Systems

Leading PCB assembly services feature:

- Laser-aligned stencil printers

- 3D solder paste inspection (SPI)

- Automated cleaning stations

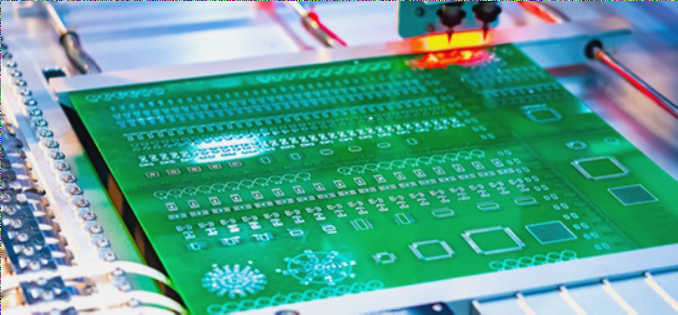

9. Component Placement Technology

Advanced PCB production facilities utilize:

- High-speed pick-and-place machines

- Vision-assisted component alignment

- Automated feeder systems

10. Soldering Systems

Professional PCB manufacturing solutions include:

- Nitrogen reflow ovens

- Selective soldering machines

- Wave soldering systems

11. Comprehensive Testing Equipment

Final quality assurance involves:

- Automated optical inspection (AOI)

- In-circuit test (ICT) systems

- Flying probe testers

Choosing the Right PCB Manufacturing Partner

When selecting a professional PCB manufacturer for your export business, verify they maintain:

- ISO-certified production facilities

- Modern equipment with regular maintenance

- Capability for your specific board requirements

Top-tier Chinese PCB suppliers combine advanced equipment with technical expertise to deliver high-reliability boards for global markets.