What Does It Take To Set Up A PCB Manufacturing Factory: The Complete Guide

The Critical Role of PCBs in Modern Electronics

Printed Circuit Boards (PCBs) form the foundation of virtually all electronic devices in today’s interconnected world. From smartphones and computers to wearable technology and industrial equipment, these essential components power our digital lifestyle. As global demand for electronics continues to surge, establishing a PCB manufacturing facility presents a lucrative business opportunity for entrepreneurs and investors alike.

Essential PCB Manufacturing Equipment for Your Factory

Building a successful PCB production line requires careful planning and substantial investment in specialized machinery. Below we outline the core equipment needed for high-quality PCB fabrication:

1. Imaging and Etching Systems

- Photoimaging machines for precise circuit pattern transfer

- Advanced etching equipment for copper removal

- Automated stripping machines for resist removal

2. Metal Plating Equipment

Essential for creating durable conductive paths, these systems include:

- Electrolytic copper plating machines

- Tin-lead or lead-free plating systems

- Gold plating equipment for high-end applications

3. Solder Application and Inspection

“Automated solder paste printing is critical for achieving consistent results in high-volume PCB production.”

- Precision stencil printers

- 3D solder paste inspection (SPI) systems

- Automated optical inspection (AOI) equipment

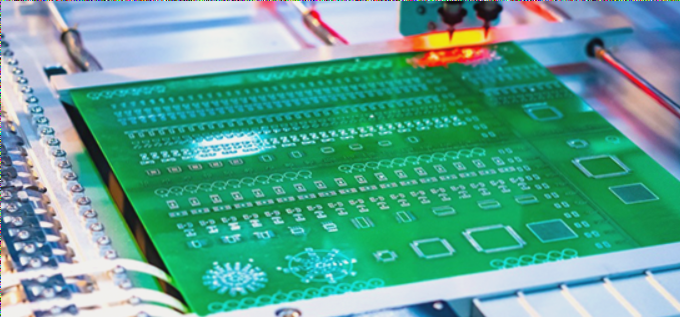

4. Component Placement Technology

Modern PCB assembly lines require:

- High-speed pick-and-place machines

- Multi-functional chip shooters

- Fine-pitch placement systems

5. Soldering Systems

- Reflow ovens for surface mount technology (SMT)

- Wave soldering machines for through-hole components

- Selective soldering equipment for mixed-technology boards

6. Testing and Quality Control

Essential for ensuring reliable PCB performance:

- In-circuit test (ICT) systems

- Flying probe testers

- Boundary scan equipment

Critical Raw Materials for PCB Production

Operating a PCB manufacturing business requires maintaining adequate inventory of essential materials:

Substrate Materials

- FR-4 epoxy laminate (most common)

- High-frequency materials (Rogers, PTFE)

- Flexible polyimide substrates

Conductive Materials

- Electrolytic copper foil (various weights)

- Copper-clad laminates

- Conductive inks for special applications

Protective and Marking Materials

- Solder mask (liquid photoimageable)

- Silkscreen inks for component marking

- Surface finishes (HASL, ENIG, OSP)

Assembly Components

- Solder paste (lead-free formulations)

- Solder wire for rework stations

- Fluxes and cleaning chemicals

Regulatory Compliance and Certifications

Establishing a legitimate PCB manufacturing operation requires obtaining proper certifications:

Essential Certifications

- ISO 9001:2015 Quality Management

- UL certification for safety standards

- IPC standards compliance (IPC-A-600, IPC-6012)

Environmental Regulations

- RoHS compliance for hazardous substances

- REACH chemical regulations

- WEEE directive for electronic waste

Strategic Considerations for PCB Factory Setup

When planning your PCB manufacturing business in China or other locations, consider:

- Location advantages (supply chain access, labor costs)

- Target market requirements

- Production capacity planning

- Technology roadmap for future expansion

Conclusion: Building a Future-Ready PCB Manufacturing Business

The growing demand for high-quality printed circuit boards presents significant opportunities for entrepreneurs. By investing in the right PCB production equipment, maintaining proper material inventory, and obtaining necessary certifications, you can establish a competitive PCB manufacturing facility capable of serving global electronics markets.