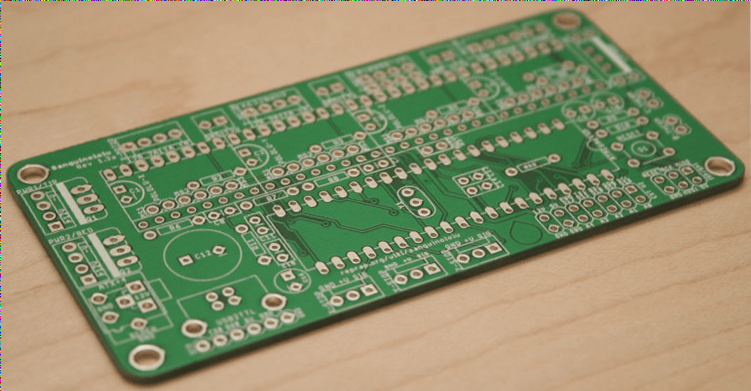

SMT Chip Processing and White Residue on PCB Circuit Boards

SMT chip processing plays a critical role in PCB board soldering during production. However, the presence of white residues on PCB circuit boards post-soldering can impact both appearance and performance. Let’s explore the causes of white residues and how to address them:

- Improper use of flux, such as rosin flux, during the assembly process can leave white spots. Consider switching to a different flux or using strong solvents for cleaning.

- Residues left on the circuit board during production can lead to white spots over time. Utilize strong solvents for effective cleaning.

- White spots may appear due to improper processing of the circuit board. Clean affected boards with a strong solvent.

- Incompatibility of flux with oxidation maintenance can cause issues. Try using a different flux to resolve the problem.

- Solvents used during manufacturing can degrade PCB raw materials, resulting in white residues. Minimize storage time and pay attention to solutions used in the nickel plating process.

- Old flux absorbing moisture or solder remaining too long before cleaning can lead to white spots. Use fresh flux and clean promptly.

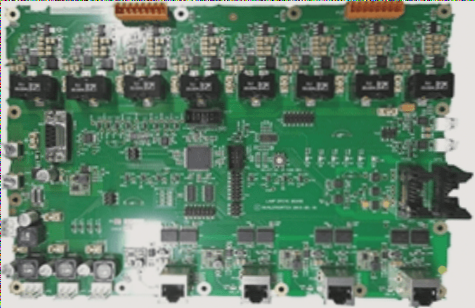

Applying Anti-Corrosion Paint in SMT Chip Processing

When applying anti-corrosion paint, ensure proper techniques to avoid issues like uneven surfaces. Thicker coatings may offer waterproof and heat-insulating properties but can affect PCB appearance if excessively applied.

It’s essential to balance cost and adherence to PCB thickness standards when applying anti-corrosion coatings. Aim for a thin yet effective coating to maintain product quality without deviating from industry standards.

For any PCB manufacturing requirements, feel free to contact us.