Optimizing Robotic PCB Assembly: Key Applications and Selection Factors for Export Businesses

Why Robotic PCB Assembly Matters in Modern Automation

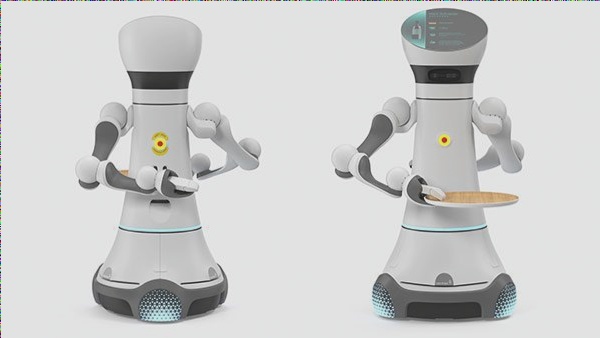

The global shift toward industrial automation has made robotic PCB assembly a cornerstone technology for manufacturers worldwide. As a leading PCB manufacturer in China, we understand how printed circuit boards serve as the neural network of robotic systems, controlling everything from precision motion feedback to sensor integration.

The Five Critical Elements of Robotic Systems

- Sensors – Environmental data collection

- Motion mechanisms – Physical movement execution

- Structural body – Mechanical framework

- Power supply – Energy delivery system

- PCB control system – Electronic command center

How to Select the Best PCB for Robotic Applications

When evaluating automation PCB solutions for export markets, consider these critical design factors:

1. Alignment Width Optimization

Proper trace width calculation prevents thermal damage while maintaining signal integrity. Our robotic PCB assembly services recommend:

- Minimum 90-degree turn avoidance

- Power/ground plane separation standards

- Current-carrying capacity verification

2. Precision Drill Sizing

For high-reliability robotic PCBs, we implement:

- 0.008″ minimum hole diameter

- Solder fill compensation (+15-20% oversizing)

- IPC-2221 clearance standards

Overcoming Challenges in Robotic PCB Manufacturing

As a trusted PCB supplier for automation, we address these critical concerns:

Quality Assurance Protocols

Our export-quality PCB production follows:

- ISO 9001:2015 certified processes

- IPC-6012 Class 3 standards

- Automated optical inspection (AOI)

Design Risk Mitigation

We employ advanced DFM analysis including:

- 3D design rule checking (DRC)

- Signal integrity simulations

- Thermal stress testing

“In robotic applications where human safety depends on flawless operation, zero-defect PCB manufacturing isn’t optional – it’s an absolute requirement for global export markets.”

Why Choose Our Robotic PCB Assembly Services?

For international buyers seeking reliable PCB manufacturers in China, we offer:

- Customized solutions for industrial automation systems

- ROI-focused production with 30% faster lead times

- Full compliance with international export standards

- End-to-end PCB assembly for robotics services

Contact our export specialists today to discuss your custom robotic PCB requirements and learn how our solutions can enhance your automation projects.