Soldering Process in PCB Manufacturing

1. Solder Paste Printing Machine

A modern solder paste printer is a crucial component in PCB assembly. It involves applying solder paste onto the circuit board pads through a stencil, preparing them for component placement.

2. Mounter

The mounter, also known as a Surface Mount System, accurately places surface-mounted components onto the PCB pads after the solder paste printing process. It comes in manual and automatic variants.

3. Reflow Soldering

Reflow soldering is a vital step in electronics manufacturing, where solder paste is melted to create reliable connections between components and the PCB. Heating the assembly to a specific temperature profile ensures proper solder melting and solidification.

Additional Information on Reflow Soldering:

- Heating air or nitrogen to a high temperature in the reflow process aids in melting solder for bonding.

- Advantages include precise temperature control, oxidation prevention, and cost-effective manufacturing.

4. AOI Detector

Automatic Optical Inspection (AOI) technology detects soldering defects by scanning PCBs with cameras and comparing solder joints against predefined parameters stored in a database.

5. Component Trimming Machine

This machine is used to cut and reshape pin components for PCB assembly.

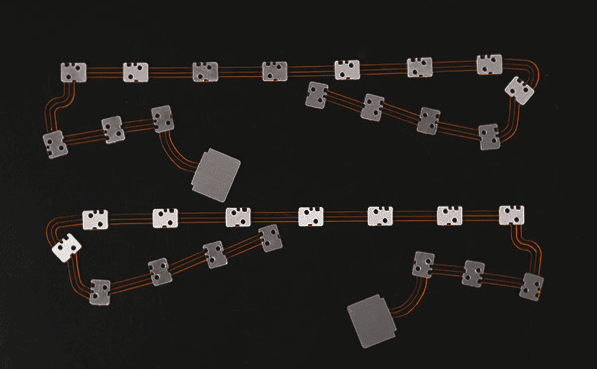

6. Wave Soldering

Wave soldering involves making the soldering surface of a plug-in board directly contact high-temperature liquid tin for soldering purposes, using solder bars.

7. Tin Furnace

A tin furnace is a welding tool that ensures good welding consistency and high work efficiency in electronic soldering processes.

8. Plate Washer

A plate washer device effectively cleans PCBA boards, removing residues left after soldering.

9. ICT Test Fixture

ICT testing involves using test probes to check for open circuits, short circuits, and soldering quality on PCBAs.

10. FCT Test Fixture

Functional Testing (FCT) creates simulated operating environments to evaluate the functionality of PCBs under different design states.

11. Aging Test Frame

The aging test frame batch tests PCBA boards to simulate long-term user operations and identify potential issues.