The Importance of Turnkey PCB Manufacturing and Assembly

Turnkey PCB manufacturing and assembly play a vital role in the production of electronics and digital devices. Previously, this process was cumbersome and costly, but with advancements in technology, it has become more streamlined and efficient.

Benefits of Turnkey PCB Assembly

Turnkey PCB assembly involves designing, manufacturing, and assembling printed circuit boards under one roof. This integrated approach ensures better quality control and faster turnaround times compared to consigning PCB assembly.

Clients have the option to either entrust the entire process to a single provider or source components from multiple manufacturers.

The 6 Stages of Turnkey PCB Manufacturing and Assembly

Manufacturers now follow a structured approach consisting of six main stages to ensure a smooth and cost-effective turnkey PCB production process. These stages include:

1. High-Quality Prototyping

Modern manufacturers utilize advanced software for designing and prototyping PCBs, reducing the risk of errors and optimizing the use of electronic components. This results in cost-effective prototyping and efficient design validation.

By offering their designs online, manufacturers can attract potential clients and secure projects effectively.

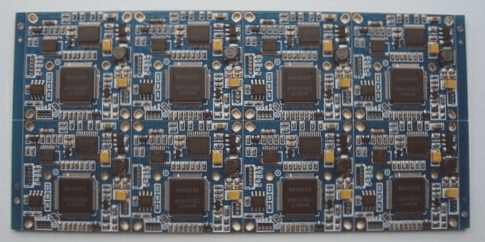

2. Manufacturing of Turnkey PCBs

Once the design is approved, manufacturers proceed with the manufacturing of turnkey PCBs. From simple to complex designs, the use of software streamlines the production process, ensuring high-quality outputs.

- Streamlined production process

- Cost-effective prototyping

- Efficient design validation

- Integrated approach for better quality control

- Faster turnaround times

Cost Factors in Turnkey PCB Design

- Manufacturers’ pricing varies based on the complexity of the PCB design.

- Clients often provide materials or components for the manufacturing process.

- Manufacturers undertake various steps like board preparation, copper addition, layer printing, and bonding during manufacturing.

The cost of turnkey PCB projects is influenced by manufacturing complexity and design type.

Electronic Component Assembly

Turnkey PCB manufacturing involves assembling PCBs to serve as the core of electronic devices. Many clients opt to have both PCB manufacturing and assembly done by the same manufacturer for seamless integration.

- Consolidating manufacturing and assembly ensures optimal performance of electronic devices.

- Companies with manufacturing contracts rely on manufacturers for component assembly.

- Manufacturers follow client specifications for assembling electronic components.

Choosing the same manufacturer for PCB manufacturing and component assembly streamlines the process, enhancing device functionality and ensuring timely delivery.

Turnkey PCB Assembly Testing

After assembly, rigorous testing is crucial to confirm the correct placement of components. Manufacturers conduct initial and final tests to validate the circuit board’s functionality.

- Testing includes inspecting soldering and assembly quality for optimal performance.

- The circuit board acts as the central control unit for the entire device.

Final testing involves selecting appropriate packaging to match your product’s image, ensuring thorough quality checks.

Secure Storage and Management

With large orders, electronic companies rely on manufacturers for proper storage and management of PCB assemblies. Manufacturers must efficiently handle storage and delivery to meet client expectations.

Outsourcing storage to manufacturers with expertise ensures efficient management and quality control.

Integration System

Choosing a manufacturer for PCB assembly via API integration signifies entrusting them with the entire order preparation and delivery process.

Benefits of Turnkey PCB Assembly

- Simplified Process: The electronic device company streamlines the ordering process by assessing the portfolio and handling the entire PCB design and manufacturing process.

- Stress-Free Experience: When opting for turnkey PCB assembly, you can relax knowing that the manufacturer will take care of the order placement, production, and timely delivery.

- Efficient Delivery: Expect organized, well-packed PCBs to arrive on schedule, eliminating any shipping concerns.

With turnkey PCB assembly, you can wave goodbye to the hassle of coordinating with multiple companies for shipment. The manufacturer handles everything, allowing you to concentrate on growing your business, devising effective marketing strategies, and paving the way for success.

Conclusion

In summary, turnkey PCB assembly offers a hassle-free solution where the burden of post-order worries is lifted off your shoulders. Once you’ve provided the necessary product details and expectations, you can shift your focus back to your core business activities. From planning to delivery, the manufacturer manages the entire process, ensuring your PCB assembly needs are met efficiently and promptly.