Essential Guidelines for Choosing the Best PCB Design Supplier for Your Export Business

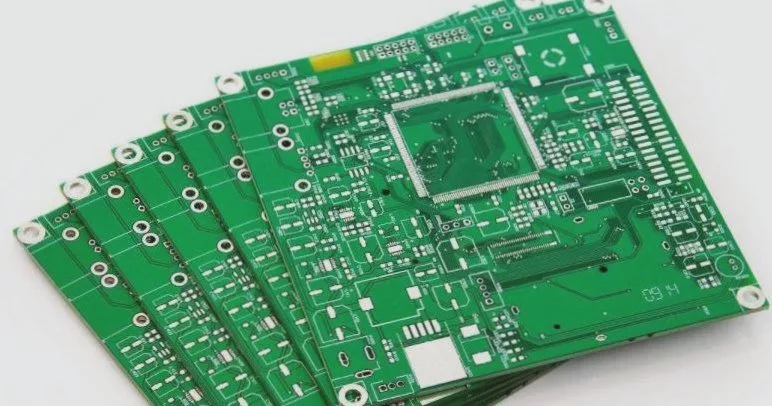

Modern electronics rely on Printed Circuit Boards (PCBs) to house and connect intricate components efficiently. With advancements in PCB manufacturing technology, businesses seeking high-quality PCB design suppliers must understand key industry standards to ensure optimal performance and cost-efficiency.

Why PCB Design Matters in Global Manufacturing

PCBs serve as the backbone of electronic devices, containing over 100 meters of copper wiring in compact layouts. As demand grows for reliable PCB manufacturers in China and other manufacturing hubs, following proven design guidelines becomes critical for export-ready products.

Key PCB Design Guidelines for International Suppliers

1. Establish Clear Design Rules Before Layout

“A well-planned PCB design prevents costly revisions in production” – Industry Expert

Top-tier PCB design suppliers begin with comprehensive planning:

- Conduct market research on similar products

- Verify schematics with clients

- Select appropriate board materials

- Analyze thermal and electrical requirements

2. Strategic Component Placement Techniques

Proper component arrangement affects heat dissipation, manufacturing costs, and product reliability:

- Place power components first for optimal thermal management

- Minimize net crossing to reduce via usage

- Group digital and analog sections separately

- Allow adequate spacing between components

3. Advanced Routing Strategies for Export-Quality PCBs

Effective routing separates professional PCB manufacturers from amateurs:

- Use appropriate trace widths for current loads

- Maintain symmetrical routing patterns

- Implement dedicated power and ground planes

- Consider thermal relief patterns for heat-sensitive designs

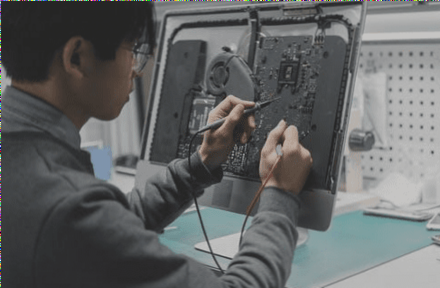

Quality Assurance in PCB Manufacturing

Reputable PCB suppliers in China implement rigorous testing protocols:

- Design Rule Checks (DRC)

- Electrical Rules Checks (ERC)

- Quality Assurance (QA) testing

- Design for Manufacturability (DFM) analysis

Choosing the Right PCB Design Partner

When selecting a PCB design supplier for export business, consider:

- Experience with international standards

- Advanced design software capabilities

- Multi-layer PCB expertise

- Proven quality control processes

- Competitive pricing for bulk orders

The global PCB market continues evolving with miniaturization trends and advanced materials. Partnering with an experienced PCB manufacturer in China ensures your products meet international quality standards while remaining cost-competitive in export markets.

By implementing these professional guidelines, businesses can develop high-performance PCBs that stand up to rigorous international market demands while optimizing production efficiency and reliability.