Optimizing PCB Design: Mastering Return Paths for Superior Signal Integrity

Understanding Return Path Fundamentals in High-Speed PCB Design

In modern PCB fabrication, current flow follows the path of least impedance rather than least resistance – a critical distinction for engineers designing high-frequency circuits. The return path represents the current’s journey back to its source, and optimizing this path significantly enhances signal integrity and reduces electromagnetic interference (EMI).

Why Proper Return Paths Matter in Today’s PCB Landscape

- Increasing demand for miniaturized PCB designs with higher component density

- Growing adoption of flexible and rigid-flex circuits in consumer electronics

- Dramatic reduction in operating voltages across modern devices

- Need for faster signal transmission with minimal distortion

Advanced Routing Techniques for Optimal Return Paths

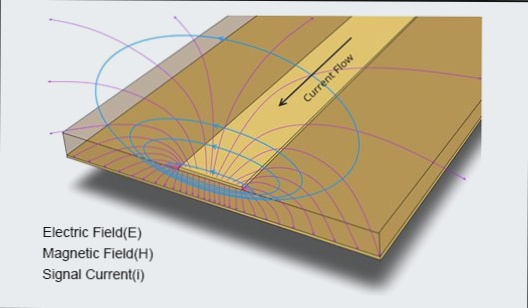

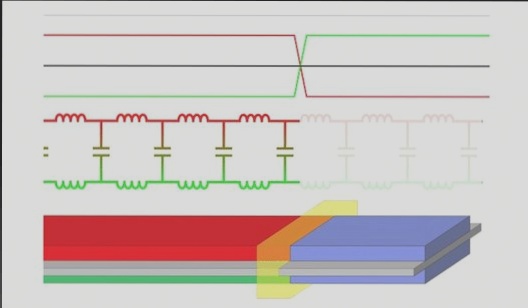

When alternating current flows through a circuit, electric fields permeate surrounding conductors, potentially affecting nearby circuits. The propagation delay of magnetic field changes – occurring at fractions of light speed – creates timing challenges in high-speed PCB design.

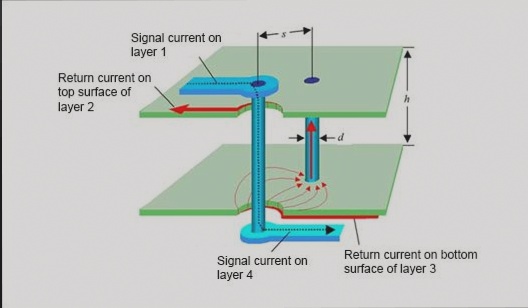

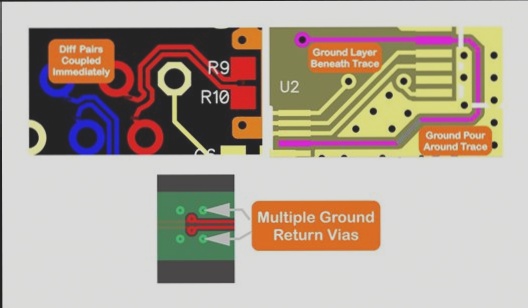

“Always provide a ground return path in the same layer (or adjacent layer) for single-ended signals, power planes, and differential pairs to prevent unwanted current establishment in nearby conductors.”

Key Considerations for Return Path Implementation

- Inductive and capacitive coupling forms return paths when not explicitly designed

- Unplanned return paths can create signal integrity issues and crosstalk

- Proper return path design reduces radiated emissions and improves EMC performance

The Science Behind Path of Least Impedance

High-speed signals naturally follow the path of least impedance, not resistance. Many engineers focus solely on the resistive component, neglecting the crucial reactive elements that dominate at higher frequencies. As frequency increases and rise/fall times decrease, the reactive impedance components become increasingly significant.

Frequency-Dependent Return Path Behavior

- Low frequency: Return current flows directly from load to source

- High frequency: Mutual inductance creates low-impedance paths beneath traces

- Ground plane return currents mirror signal layer traces at RF frequencies

Best Practices for Return Path Implementation

Implement these PCB design strategies to optimize your return paths:

- Route fast-changing signals with immediate adjacent return paths

- Maintain close proximity of differential pairs exiting package pins

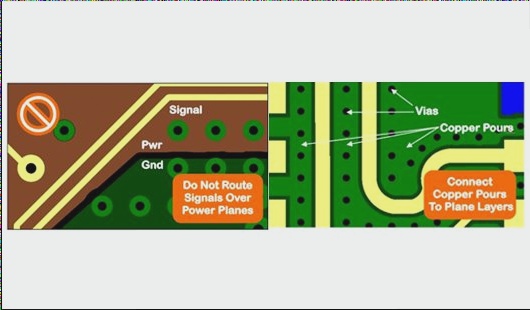

- Surround clock signals with ground pours and uninterrupted ground planes

- For FCC compliance, route high-speed signals between ground planes with via stitching

Two Essential Techniques to Reduce Ground Noise

- Maintain differential pair proximity throughout entire routing paths

- Provide ground return paths directly beneath or adjacent to signal lines

Common Pitfalls in Return Path Design

Signals traversing power planes before reaching ground layers can share electric fields with power planes, creating signal noise and integrity issues. Other frequent mistakes include:

- Insufficient ground return vias for high-speed signals

- Improper stackup design that creates impedance discontinuities

- Neglecting return path analysis in multi-layer PCB designs

Conclusion: Implementing Effective Return Path Strategies

Careful return path planning prevents unwanted currents and ensures optimal PCB performance. For high-frequency designs, always provide dedicated ground return paths and vias for all critical signals. Partner with experienced PCB manufacturers in China like WellCircuits to implement these advanced techniques in your next project.

Ready to optimize your PCB designs? Contact our team of experts today to discuss your high-speed PCB fabrication and assembly requirements.