PCB Trace Design for High-Speed Signals

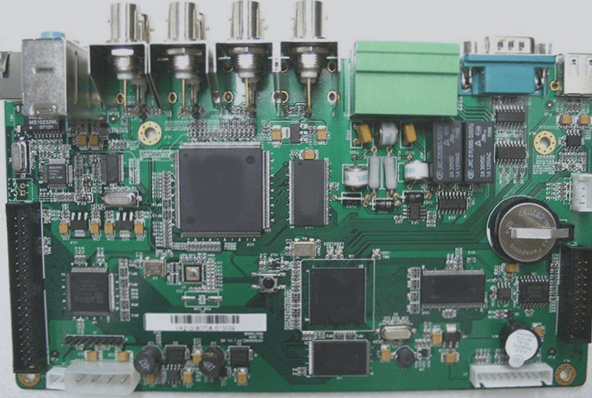

When designing a PCB, it’s crucial to consider the impact of traces on signal delay, especially for high-frequency signals. Serpentine traces are often used to compensate for delay discrepancies among signal lines in the same group. Clock lines, like CIClk and AGPClk, are critical examples that require precise timing without additional logic processing.

The equalization of line lengths in high-speed digital PCBs is essential to ensure data integrity within a single cycle. Excessive delay gaps between signals can lead to data misinterpretation. Ideally, the delay difference should not exceed 1/4 of a clock cycle. Factors affecting delay include line width, length, copper thickness, and board layer structure.

While long traces can increase distributed capacitance and inductance, improving signal quality, it’s vital to manage inductance carefully. Serpentine traces should maintain a spacing of at least twice the line width to minimize inductance-induced phase shifts in signal harmonics.

In computer boards, serpentine traces serve various functions based on specific requirements. They can act as filter inductors to enhance circuit interference immunity. For critical signals like HUBLink in INTEL HUB architecture, precise trace length matching is crucial to prevent timing issues, often achieved through winding techniques.

Overall, when implementing serpentine traces, ensuring proper line spacing and length alignment is key. Whether for impedance matching, inductance coil applications, or signal integrity maintenance, thoughtful PCB trace design plays a vital role in electronic system performance.