Understanding PLCC and LCC Packages for PCB Assembly

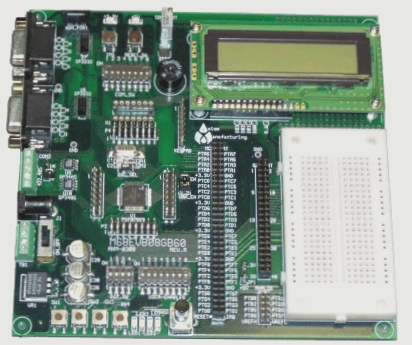

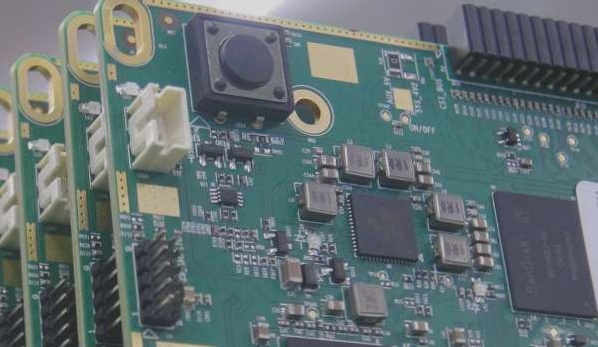

For those familiar with PCBs, understanding different electronic component packages is crucial. One such option is PLCC, a Plastic Leaded Chip Carrier, offering benefits in prototype PCB assembly.

What is PLCC?

PLCC stands for Plastic Leaded Chip Carrier, a four-sided ‘J’-leaded surface mount device commonly colored green. It supports direct soldering onto the PCB and socket mounting, facilitating integrated circuit attachment.

PLCC Design and Benefits

- Rectangular or square shapes

- Cost-effective compared to ceramic leaded chip carriers

- ‘J’ shape simplifies soldering and socket mounting

- Easy replacement without PCB replacement if damaged

- Thermal dissipation capability varies

PLCC vs LCC Package

While PLCCs and LCCs share similarities, they differ significantly:

- PLCCs have leads, LCCs do not

- LCCs are more versatile in mounting and dismounting

- PLCCs support soldering and socket mounting, LCCs use surface mounting

Benefits of PLCC Packages

- ‘J’ Shape saves space and is efficient

- Attachment options: soldering or socket mounting

- Chip protection during soldering

- Cost-effective compared to ceramic leadless chip carriers

Understanding PLCCs is essential for PCB projects. Contact experienced PLCC service providers for professional assistance tailored to your needs. Reach out for guidance on PLCCs or related services at your convenience.