TU-662: High Thermal Reliability Laminate and Prepreg

Discover the Superiority of TU-662/TU-66P for Your PCB Needs

Looking for a reliable solution for your PCB applications? TU-662/TU-66P laminate/prepreg is crafted from top-notch woven E-glass coated with an epoxy resin system. This unique combination not only provides UV-blocking properties but also ensures compatibility with Automated Optical Inspection (AOI) processes. Whether you need exceptional thermal cycle resistance or durability during assembly, TU-662 laminates are the ideal choice. They offer outstanding coefficient of thermal expansion (CTE), excellent chemical resistance, and thermal stability suitable for lead-free soldering assembly with general CAF resistance.

Applications in Various Industries

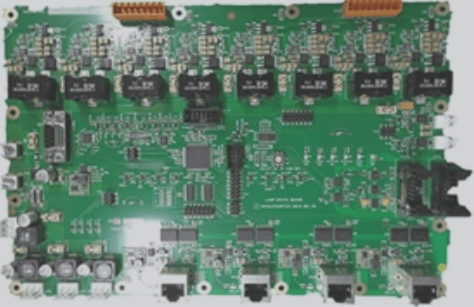

- Automotive

- Consumer Electronics

Key Features of TU-662/TU-66P

- Lead-free process compatibility

- Superb coefficient of thermal expansion

- Anti-CAF properties

- Compatibility with FR-4 processing conditions

- Outstanding chemical and thermal resistance

- Fluorescent for AOI inspections

- UV-blocking for optical clarity

- High interlayer bonding strength with optimal resin flow

- Low moisture absorption

Explore the Material Properties

- Tg (DMA): 160°C

- Tg (DSC): 150°C

- Tg (TMA): 140°C

- Td (TGA): 340°C

- CTE z-axis (50 to 260°C): 3.2%

- T-260/T288: >60 min / >10 min

- Permittivity (RC 50%) @1GHz: 4.3

- Loss Tangent (RC 50%) @1GHz: 0.014

Trusted Industry Approvals

- IPC-4101 Type Designation: /21, /98, /99, /101

- UL Designation – ANSI Grade: FR-4.0

- UL File Number: E189572

- Flammability Rating: 94V-0

- Maximum Operating Temperature: 130°C

Standard Availability Options

- Thickness: 0.002” [0.05mm] to 0.062” [1.58mm], available in sheet or panel form

- Copper Foil Cladding: Various options for different needs

- Prepregs: Available in roll or panel form

- Glass Styles: Choose from a variety of options like 106, 1080, 2113, and more

For all your PCB and PCBA inquiries, feel free to reach out to us at info@wellcircuits.com.