How to Design a Printed Circuit Board Yourself: A Comprehensive Guide

Understanding PCB Basics for DIY Design

Printed circuit boards (PCBs) form the backbone of modern electronics, found in everything from smartphones to industrial machinery. As a leading PCB manufacturer in China, WellCircuits Electronics Services provides this step-by-step guide to help international buyers understand how to design a PCB from scratch for prototyping or small-scale production.

Essential Components of PCB Design

- Substrate Material: Typically FR-4 fiberglass for rigidity and insulation

- Copper Layer: Conductive pathways etched onto the substrate

- Solder Mask: Protective green/brown coating preventing short circuits

- Silkscreen: Component labels for assembly guidance

Step-by-Step PCB Design Process

1. Substrate Preparation and Copper Lamination

The foundation begins with a non-conductive substrate laminated with copper foil. For high-quality PCB fabrication, we recommend using 1oz copper for standard applications.

2. Circuit Pattern Transfer

Using photolithography, your design transfers to the copper layer:

- Apply UV-sensitive photoresist

- Expose through your circuit pattern mask

- Develop to remove unexposed areas

3. Etching and Drilling

Chemical etching removes unwanted copper, leaving only your circuit traces. For multi-layer PCB assembly, precision drilling connects internal layers via plated through-holes.

“Proper hole plating ensures reliable interlayer connections – a critical factor in professional PCB manufacturing.” – WellCircuits Engineering Team

4. Solder Mask Application

The iconic green coating serves multiple purposes:

- Prevents solder bridges between components

- Protects copper from oxidation

- Provides electrical insulation

5. Silkscreen Marking

Component labels and logos applied via epoxy ink help with:

- Accurate part placement during PCB assembly services

- Troubleshooting and repairs

- Quality control verification

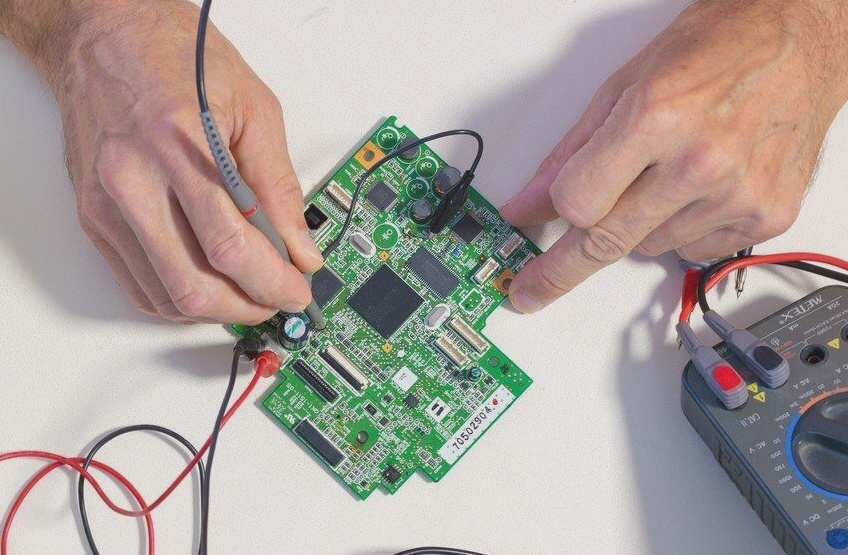

Critical Testing Procedures

Before deploying your DIY PCB, conduct these essential tests:

Electrical Testing

- Continuity checks for open circuits

- Insulation resistance measurements

- High-voltage dielectric tests

Automated Optical Inspection (AOI)

Fast, accurate detection of:

- Trace defects

- Solder mask imperfections

- Silkscreen errors

When to Partner with a Professional PCB Manufacturer

While DIY PCB design works for prototypes, consider China PCB manufacturing services for:

- High-volume production runs

- Complex multi-layer designs

- Specialized materials (high-frequency, flexible PCBs)

- Strict quality compliance (IPC Class 2/3)

Why Choose WellCircuits for Your PCB Needs?

As a trusted PCB supplier for international trade, we offer:

- DFM (Design for Manufacturing) analysis

- Fast-turn prototyping (24-48 hours)

- Competitive MOQs for export businesses

- Complete documentation for customs clearance

For more guidance on how to select the right PCB materials or best PCB manufacturing processes, visit WellCircuits Electronics Services – your partner in global electronics trade solutions.