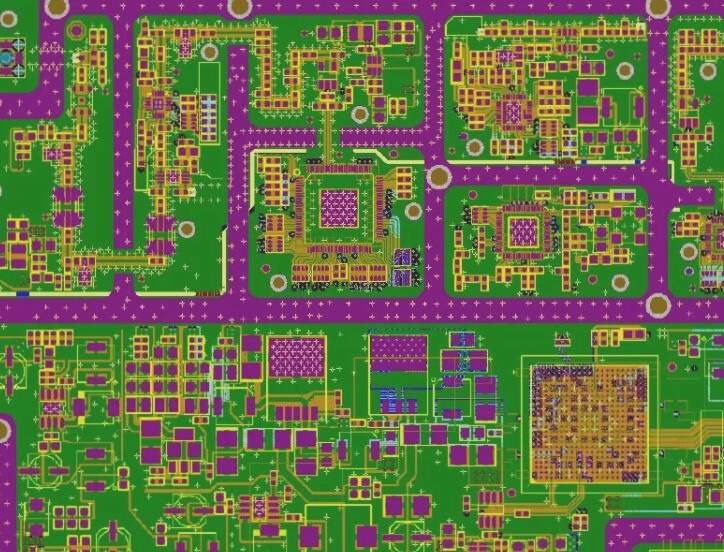

The Advantages of SMT Chip Processing Packaging

1. Smaller Size and Higher Installation Density

SMT chip electronic components are significantly smaller and lighter than traditional components, reducing electronic equipment size by 40% to 60% and mass by 60% to 80%. The grid for SMT components has evolved to as small as 0.5mm, enhancing relative density.

2. High Reliability and Enhanced Anti-Vibration Ability

SMT chip components offer high reliability, compact size, lightweight construction, and strong anti-vibration capabilities. Automated production ensures high installation reliability with low defect rates in solder joints.

3. Superior High-Frequency Characteristics and Reliable Performance

Chip components with minimized parasitic inductance and capacitance improve high-frequency characteristics and reduce electromagnetic interference. SMC and SMD circuits can reach frequencies up to 3 GHz, enhancing performance.

4. Improve Productivity and Achieve Automated Production

Automating PCB production with SMT technology increases efficiency and reliability. Automatic placement machines enhance component installation density and are effective for handling small electronic components.

5. Reduce Costs and Lower Expenses

SMT processing reduces PCB area usage, hole numbers, and frequency of circuit debugging, resulting in significant cost savings on materials, labor, and transportation. Overall costs can be reduced by 30% to 50%.

PCB Circuit Board Substrate Material Classification

The PCB substrate, comprising resin, reinforcing materials, and conductive materials, is crucial in PCB production. Common substrates include epoxy resin, phenolic resin, paper-based or glass cloth reinforcing materials, and copper foil as the standard conductive material.

PCB Substrate Material Classification:

- According to Different Reinforcing Materials:

- Paper substrate (FR-1, FR-2, FR-3)

- Epoxy glass fiber cloth substrate (FR-4, FR-5)

- Composite substrate (CEM-1, CEM-3, Composite Epoxy Material Grade-3)

- HDI (High-Density Interconnect) PCB sheet (RCC)

- Special substrates (metal, ceramic, thermoplastic)

- According to Flame Retardant Performance:

- Flame-retardant type (UL94-V0, UL94-V1)

- Non-flame retardant type (UL94-HB grade)

Types of PCB Boards Based on Resins:

- Phenolic Resin PCB Board

- Epoxy Resin PCB Board

- Polyester Resin PCB Board

- BT Resin PCB Board

- PI Resin PCB Board