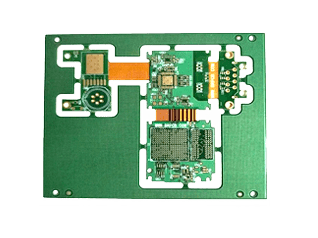

Rigid-flex PCBs provide the advantages of both rigid and flexible boards to produce compact and innovative circuits which deliver reliable performance across various industries. The combination of multiple rigid PCB assemblies into one module achieves both space and weight efficiency alongside mechanical stability. PCBs used in aerospace, medical, automotive, and communication applications demand precise design work and manufacturer collaboration due to their high-reliability requirements. The creation of advanced multilayer designs for commercial and high-end industrial applications utilizes polyimide and FR-4 materials along with sophisticated techniques.

Design Nuances and Considerations

Rigid-flex PCBs combine rigid board routing density with flexible circuit features which makes them perfect for applications involving high vibration levels. The combination of rigid and flexible elements in their design requires meticulous attention to mechanical and electrical specifications. The design process requires choosing the optimal bend radius to avoid mechanical failures and signal quality issues while ensuring signal integrity and EMI control in flexible areas and handling tear drop design constraints to improve through-hole stability.

Evolutionary Advancements in Rigid-Flex PCBs

Rigid-flex PCBs merge rigid and flexible substrates to produce multifunctional designs that maintain high adaptability. The combination of rigid and flexible substrates within these PCBs makes them perfect for modern applications such as smart devices and medical equipment because they require compact and reliable performance. The reliability of devices increases through the removal of delicate wiring and numerous solder joints by using rigid-flex PCBs. To achieve effective integration of this technology into innovative designs requires manufacturers’ early involvement.

Comparison of Flexible, Rigid-Flex, and Standard PCBs

Rigid-flex PCBs blend rigid portions with flexible sections within one board to provide multiple design possibilities. Standard rigid PCBs constructed from FR-4 materials do not provide flexibility but they remain economically viable for extensive production runs and fit standard device sizes.

Flexible PCBs made from polyimide or polyester materials deliver enhanced design adaptability to meet mechanical flexibility requirements in applications like wearables and medical devices.

While rigid-flex PCBs require more complex design processes and specialized materials which raise their costs, they deliver three-dimensional configuration capabilities for innovative device designs that standard rigid PCBs cannot provide.

Material Variations

The base dielectric thickness plays a major role in determining the cost of flexible laminates for rigid-flex PCBs. The choice of materials for both rigid and flexible sections is essential because of their different thermal expansion coefficients (CTEs) which impact device reliability. Design faces alignment issues when materials with distinct X and Y CTE values are combined. The fabrication process’s coverlayer and multiple lamination cycles often produce unpredictable material movement in first-run designs. In rigid-flex board shielding for controlled impedance applications you can select copper (solid or cross-hatched), shielding film, or conductive inks such as silver or carbon.

Cost Considerations

The most significant factor that raises production costs for rigid-flex PCB fabrication is the utilization of no-flow prepreg which makes these types of PCBs more expensive to produce than their rigid or flexible counterparts. Production expenses rise even more due to the complicated design requirements alongside necessary integration of multiple materials and specialized manufacturing techniques. Achieving long-term reliability and durability requires meticulous design and material selection which results in increased production costs. The design and assembly of rigid-flex PCBs demand specialized equipment and expert knowledge which adds to the manufacturing costs. The upfront costs of rigid-flex PCBs are outweighed by their space-saving capabilities and design flexibility which results in simpler assembly processes and potential long-term savings.

Benefits of Rigid-Flex Circuits

Rigid-flex circuits improve connection stability because they remove the requirement for board-to-board connectors and wiring harnesses. The technology decreases component numbers and installation complexity which leads to space optimization and enhanced mechanical stability making it advantageous for compact systems. The reduction of connectors and solder points results in decreased total costs while enhancing reliability which leads to longer product lifetimes.

Reliability and Durability

Rigid-flex PCBs improve reliability through the removal of fragile wiring and numerous solder joints which reduces connection problems in confined spaces. The high-reliability rolled annealed copper foil enables these components to endure hundreds of thousands of flex cycles in dynamic applications without experiencing failure. Standard materials enable these circuits to endure substantial warping while staying operational during 200,000 bending cycles. Polyimide materials demonstrate exceptional heat dissipation and high-temperature performance that surpasses FR-4 capabilities while delivering resistance to water, moisture, shock, and corrosion.

Adaptability to Applications

Rigid-flex PCBs provide dependable performance for applications that require structural strength and flexibility including smartphone design and aerospace systems. The flexibility and foldability of certain materials enables compact and detailed design work which makes them perfect for applications where space is limited, such as medical devices. PCBs achieve design flexibility and structural strength through materials such as polyimide and FR-4 which fulfill precise mechanical and thermal requirements. Flexible substrates enable these PCBs to support high component density alongside impedance demands while remaining multi-layered. Selecting appropriate materials along with proper design strategies results in cost savings and better production results for electronic applications.

Key Materials Used in Rigid-Flex PCBs

Copper foil laminated onto substrate layers with adhesive serves as the primary material for creating circuit paths in rigid-flex PCBs. Polyimide and polyester make up the flexible sections because of their bending adaptability while rigid sections utilize FR-4 and polyimide to maintain structural stability. Bonding materials and coverlays protect circuits and provide mechanical and environmental protection. The addition of stiffeners provides extra strength and support to regions needing better rigidity or for mounting electronic components.

Manufacturing Processes Overview

Rigid-flex PCBs combine rigid FR-4 sections with flexible polyimide layers to achieve both structural strength and design versatility. The system connects complex circuit paths and achieves interconnectivity through the combination of flexible polyimide ribbons with multilayer rigid sections used for routing traces. The production of rigid-flex PCBs needs specific materials and meticulous design to achieve long-lasting durability and dependable performance. Flexible sections maintain operational integrity through more than 100,000 flex cycles without failing which contributes to improved reliability. Flexible areas use coatings such as flexible solder resist or Coverlay according to specific application requirements.

Stages of Fabrication

The production process for rigid-flex PCBs presents greater complexity compared to traditional PCBs because they combine both rigid and flexible materials. The manufacturing process begins with selecting materials that will provide structural strength and optimal performance. The layer lamination process fuses multiple layers together by applying adhesives. The creation of vias for electrical connectivity happens through subsequent drilling and plating operations. Rigorous testing and inspection processes verify that the PCBs fulfill required performance and quality benchmarks.

Quality Control Measures

The production of Rigid-Flex PCBs follows IPC standards to maintain both reliability and cost-efficiency. IPC-2223 serves as the preferred standard for maintaining quality throughout design and production processes. The production process requires bonding rigid and flexible layers through adhesive application during layer lamination. Designers control trace width and spacing to ensure impedance management and signal integrity in high-speed circuits. These PCBs hold UL certification according to UL94/V-0 standards which guarantees their safety and quality.

Industry-Leading Practices

The Rigid-Flex and Flex products combine multiple rigid PCB assemblies into one module which delivers better reliability and stability while saving space and weight. The fusion of rigid PCBs’ durability with flexible PCBs’ adaptability enables Rigid-Flex designs to provide innovative solutions for various industries while fulfilling requirements for condensed and dependable circuit structures. When PCB designers team up with manufacturers at the start of the development process they boost both design-for-manufacturability and cost-effectiveness. Starting product development partnerships from the beginning improve both yield rates and cost efficiency. Advancements in technology have led to Rigid-Flex PCBs becoming essential components in electronic design which boost innovation across both consumer electronics and aerospace sectors.

Insights from Well Circuits

As a leading manufacturer Well Circuits produces high-quality flex, rigid-flex, and HDI-flex PCBs from China. Our flexible PCBs enable unique design possibilities while allowing smooth integration at various edges and folding areas. The company delivers advanced PCB design software to optimize the full design potential. The implementation of lightweight polyimide in Well Circuits’ products replaces the traditional FR4 material to minimize weight and space usage. Our flexible flat cables (FCC) increase product efficiency by optimizing space utilization.

Strategies from All Flex

All Flex Solutions stands as a top manufacturer of custom rigid-flex PCBs and merges the advantages of flexible circuits with traditional rigid boards. Through standard material stack-up techniques the company manufactures rigid-flex PCBs that reach up to 32 layers while maintaining efficient production. All Flex achieves cost savings and improved production efficiency through its focus on standardized stack-ups and established market processes. Their expertise enables the creation and development of rigid-flex PCBs that perform reliably in high shock and vibration demanding applications. All Flex seeks to minimize assembly expenses by using fewer components and reducing manual work which results in more cost-effective rigid-flex PCB production.

Integrating Rigid-Flex PCBs into Designs

The design of Rigid-Flex PCBs combines rigid boards’ high routing density and interconnectivity with flexible circuits’ adaptability. This distinctive blend renders these systems perfect for applications with high shock and vibration while providing mechanical stability together with space efficiency and lighter weight. Rigid-flex PCBs achieve greater reliability and fewer potential failures through their buried flexible layers compared to traditional surface-mounted connectors and flex cables. Rigid-Flex PCBs achieve better performance than conventional boards in specialized applications and provide cost advantages in certain situations despite their limited market share compared to standard PCBs.

Technological Advancements in Rigid-Flex PCBs

Rigid-flex PCBs integrate rigid and flexible parts into one unified structure which supports complex designs with both flexible bending capabilities and structural rigidity. The definition of bend regions allows these PCBs to create complex layouts while providing flexible design options for compact electronic devices. The production of these boards requires the integration of several conductive layers with either flexible or rigid insulation which creates more complexity than standard PCB creation. Specialized materials and processes create cost and complexity because they require combining rigid FR-4 or polyimide sections with flexible substrates. Following IPC guidelines and best practices enables designers to achieve long-term reliability and durability through meticulous design and material selection.

Market Expansions and Trends

The growing consumer demand for micro-sized electronic devices that require reliability and versatility increases the adoption of rigid-flex PCBs in industries including smartphones, industrial equipment, and aerospace systems. Flexible PCBs maintain structural integrity in complex designs while providing flexibility which makes them perfect for dynamic electronic applications. Advancements in rigid circuit board technology have broadened their applications across automotive, medical, military, and consumer electronics sectors. Integration requirements between electronics and RF technology necessitate the use of rigid-flex PCBs to save space and weight while accommodating dynamic flexing needs. The movement toward compact and dependable products generates more demand for rigid-flex PCBs to discard connectors and improve thermal management.

Future Potential of Rigid-Flex PCB

The growing need for smaller electronic devices that provide reliable performance and versatility makes rigid-flex PCBs increasingly essential. The combination of rigid and flexible elements in these PCBs enables the creation of intricate designs that occupy minimal space while removing the need for extra connectors and wiring harnesses. The ability of these boards to endure extreme vibration and shock (above 10,000 G-forces) makes them perfect for use in drones as well as unmanned vehicles and aerospace applications. Rigid-flex designs require more complexity and higher costs than conventional PCBs but they deliver cost-effective miniaturization while maintaining full connectivity and functionality. The high routing density and more than 20 layers of rigid-flex PCBs make them perfect for applications needing high input/output connectivity and upcoming electronic advances.