The Evolution of Surface Treatment Technology in PCB Manufacturing

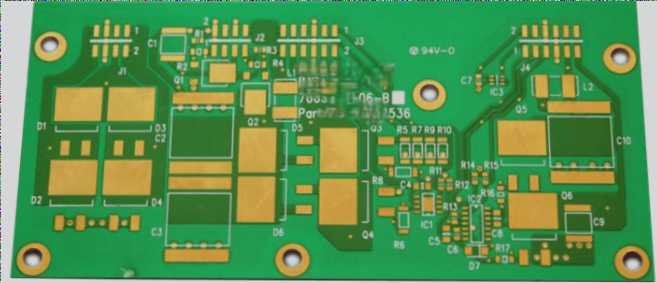

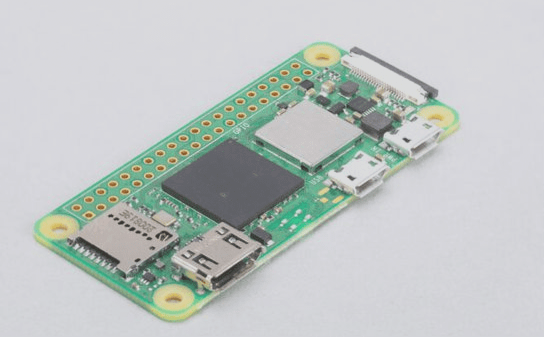

Modern PCB circuit boards rely on advanced surface treatment technologies that have evolved from traditional plating techniques. These methods incorporate scientific principles from various disciplines such as materials science, mechanics, electronics, and nanomaterials. The goal is to enhance the surface properties and performance of solid materials, resulting in improved electrical conductivity, heat resistance, oxidation resistance, wear resistance, and other specialized functions.

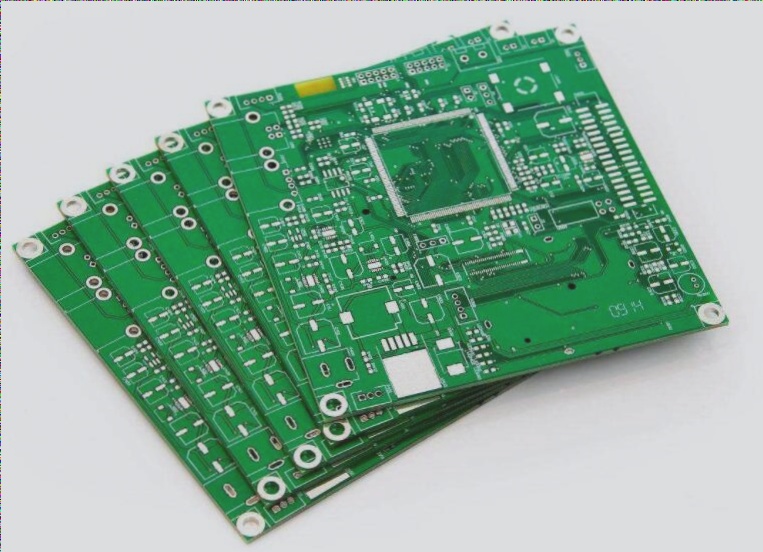

Key Considerations for Effective Surface Coating in PCB Manufacturing

For PCB manufacturers focusing on fingerprint module production, achieving an economical and high-quality surface coating is essential. This process begins with a deep understanding of the technical requirements of the product design, operational environment, and potential failure modes. By selecting the right coating design and material and matching them with suitable plating processes, manufacturers can ensure optimal performance. The following principles guide the design of surface coatings:

- Performance Alignment: The coating must meet operational and environmental requirements, considering factors like stress, working medium, and temperature fluctuations.

- Substrate Compatibility: The coating should bond well with the substrate material, maintaining physical and chemical compatibility.

- Mechanical Integrity: The coating must not compromise the mechanical properties of the substrate, preserving its strength and load-bearing capacity.

- Process Feasibility: The chosen coating and process should seamlessly integrate into the PCB manufacturing workflow.

- Process Controllability: The coating process should be easily controlled within manufacturing capabilities to ensure consistent quality.

- Performance Verification: Reliable testing methods should be in place to confirm the coating meets required standards.