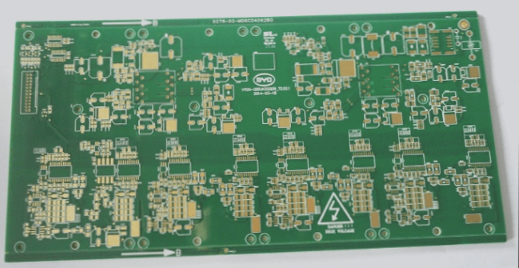

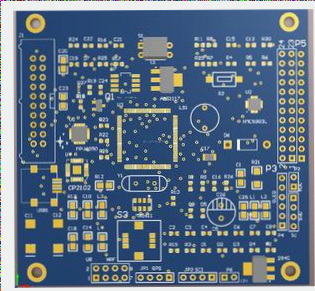

FPC: The Ultimate Guide to Flexible Printed Circuits

FPC, short for Flexible Printed Circuit, is a versatile circuit board known for its high wiring density, lightweight design, and thin profile. Commonly used in mobile phones, laptops, PDAs, digital cameras, LCMs, and various other electronic devices, FPC is a crucial component in modern technology.

The Key Characteristics of FPC

- Flexibility: FPC can bend and twist without losing functionality.

- Reliability: Made from polyimide or polyester film, FPC is highly durable and reliable.

- Cost-effectiveness: FPC offers a cost-effective solution for complex circuit designs.

Electroplating of Flexible Circuit Boards

Electroplating is a critical process in the manufacturing of FPCs. It involves depositing a layer of metal onto the surface of the circuit to enhance conductivity and durability.

Pre-treatment for FPC Electroplating

Before electroplating, it is essential to clean the copper conductor surface thoroughly to ensure proper adhesion and prevent oxidation. Special alkaline abrasives are used to remove contaminants and oxide layers, ensuring a clean surface for plating.

The thickness of the electroplating is crucial for uniform coating across the circuit. Attention to detail during the electroplating process is necessary to avoid issues like uneven plating thickness and discoloration.

Electroless Plating of Flexible Circuit Boards

For isolated line conductors that cannot serve as electrodes, electroless plating is used. This method involves plating solutions with strong chemical properties, such as electroless gold plating, to enhance conductivity.

Hot Air Leveling of Flexible Circuit Boards

Hot air leveling is another essential process in FPC manufacturing, ensuring a smooth and level surface for optimal circuit performance.

Hot Air Leveling Process for Flexible Printed Circuits

The hot air leveling process, originally designed for rigid printed circuit boards coated with lead and tin, has now been adapted for flexible printed circuits (FPCs) due to its simplicity. This process involves immersing the board vertically in a molten lead-tin bath and then using hot air to blow off excess solder.

Challenges for Flexible Printed Boards

- If the FPC cannot be submerged in solder without precautions, it must be clamped between titanium steel screens before immersion.

- The FPC surface must be cleaned and pre-coated with flux to ensure successful hot air leveling.

Potential Issues to Address

The stringent conditions of the hot air leveling process can lead to solder penetration from the edge of the cover layer beneath it, especially when the bonding strength between the cover layer and the copper foil is weak. Additionally, the moisture-absorbing nature of polyimide film can cause the cover layer to bubble or delaminate during the process due to rapid moisture evaporation.

Precautionary Measures

It is crucial to properly dry and moisture-proof the FPC before subjecting it to the hot air leveling process to prevent potential issues and ensure a successful outcome.