Solder Mask and Paste Mask in PCB Manufacturing

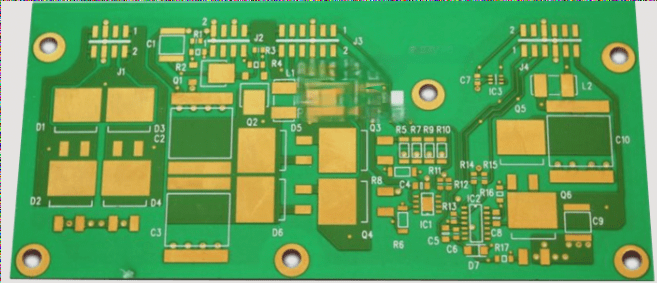

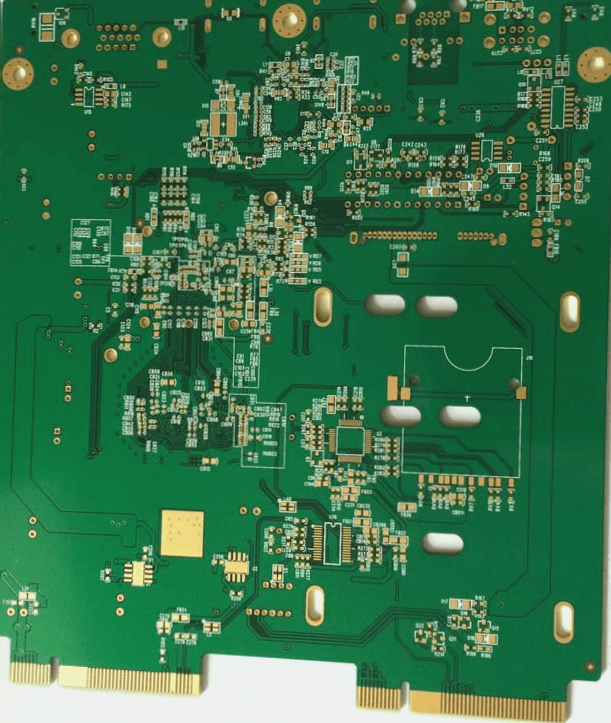

Solder Mask plays a vital role in PCB manufacturing. It is the colored layer seen on the PCB, acting as a protective coating. When applied, it exposes copper areas instead of covering them.

Wellcircuits Solder Mask Color Options

Wellcircuits offers 9 common solder mask colors. Check out the color chart below:

For more options, Wellcircuits provides Pink, Grey, Orange, and Transparent/Clear colors under the “Advanced PCB” category:

learn more about PCB Solder Masks.

Paste Mask in Surface-Mount Component Packaging

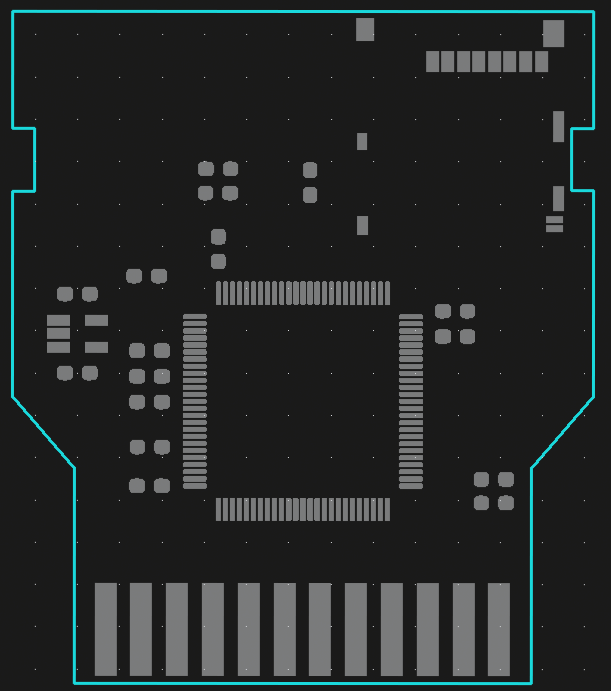

Paste Mask, or solder paste, is a stencil used in SMD component packaging. It matches the component pads and aids in the SMT process. The paste mask stencil is crucial for applying solder paste accurately.

Differences Between Solder Mask and Paste Mask

- The solder mask layer has no ink in its openings, while the paste mask layer contains solder paste.

- Solder mask is an integral part of the PCB, while the paste mask is solely for the assembly stencil.

- Solder mask applies solder mask ink, while paste mask applies solder paste.

- Solder mask is part of PCB manufacturing, while paste mask is for PCB assembly.

- Solder mask comes in various colors, while paste mask is typically gray.

For any inquiries about PCBs or PCBA, contact us at info@wellcircuits.com.