Silkscreen Standards in PCB Technology

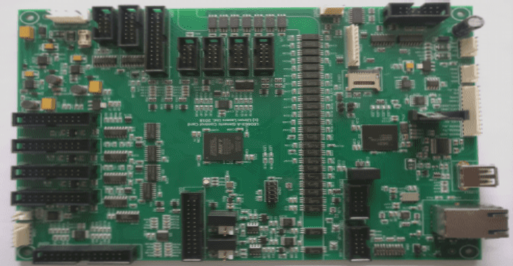

Silkscreen standards play a crucial role in ensuring the quality and efficiency of PCB assembly. Silkscreen, the printed text and graphics on a PCB, serves to identify component positions, polarity, orientation, and provide essential manufacturing information.

Key Requirements for PCB Silkscreen:

- Components and Holes: All components, mounting holes, and positioning holes must have corresponding silkscreen for easy installation and identification.

- Character Orientation: Silkscreen characters should follow a left-to-right and bottom-to-top orientation for visual consistency.

- Treatment for Pads and Traces: Avoid silkscreen on component pads and solder traces requiring soldering to ensure reliability.

- Polarized Components: Clearly mark the polarity of components like capacitors and diodes on the silkscreen.

- Directional Connectors: Indicate the correct insertion direction on the silkscreen to prevent errors.

- Board Information: Ensure clear and prominent display of board name, date, version number, and other relevant details.

- Manufacturer Details: Include complete manufacturer information and ESD markings for safety and compliance.

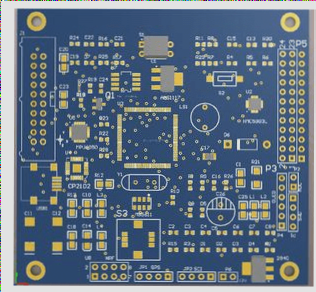

- Gerber Files: Verify that Gerber files contain all necessary layers for manufacturing accuracy.

- Consistent Designators: Match designators on the PCB with those in the Bill of Materials (BOM) for consistency.

By adhering to these silkscreen standards, PCB manufacturers can enhance the quality, reliability, and efficiency of circuit board production.

Key Factors for Quality PCB Design

- Gerber File Completeness

- Consistency in Designators

- Importance of Silkscreen Design Standards

Gerber files play a crucial role in PCB manufacturing, as they contain essential layers like routing, silkscreen, and solder mask. Ensuring that all necessary layers are included in the Gerber files is vital for achieving accuracy during production.

Consistency in design is paramount for a successful PCB assembly process. Matching the designators on the PCB with those in the Bill of Materials (BOM) is necessary to maintain coherence between the design and the BOM.

Silkscreen design standards are significant for clear component identification and correct installation, leading to improved assembly efficiency and reduced errors. Well-designed silkscreen markings, including designators, polarity indicators, and connector orientations, are crucial for precise assembly and maintenance procedures. Proper silkscreen placement prevents soldering process interference and aids in identifying PCB versions and manufacturers. Adhering to these standards enhances PCB reliability and quality, ensuring seamless production and maintenance workflows.