Selecting the Optimal PCB Thickness for High-Performance Prototypes

In the competitive world of PCB manufacturing and export, selecting the appropriate thickness for your printed circuit board is a critical decision that impacts performance, durability, and cost-efficiency. As a leading PCB manufacturer in China, we understand how thickness influences conductivity, resistance, and overall functionality in electronic devices.

Understanding PCB Thickness Standards for Global Export Markets

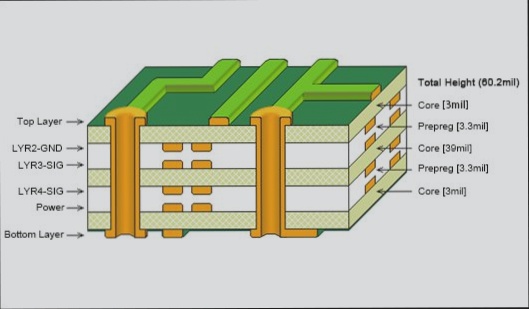

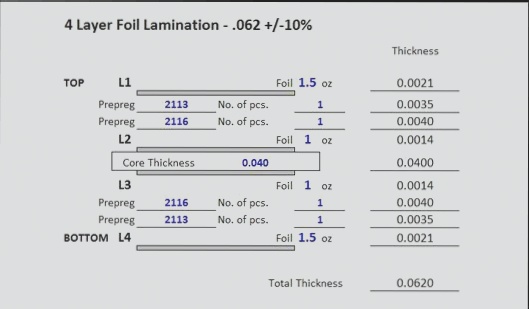

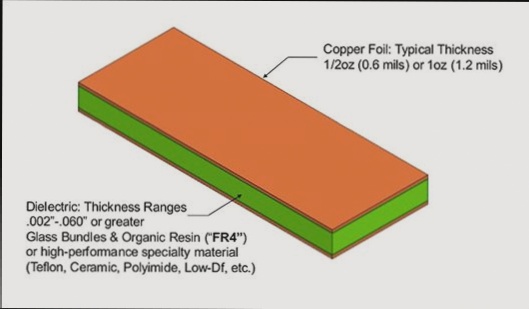

The evolution of PCB thickness options reflects changing industry demands. While the traditional standard of 0.063 inches (1.57mm) remains popular due to historical plywood substrate usage, modern multi-layer PCB fabrication techniques now offer a broader range from 0.008 to 0.240 inches.

Key Considerations for PCB Thickness Selection:

- Application requirements (consumer electronics vs industrial equipment)

- Component density and high-current PCB design needs

- Weight restrictions for portable devices

- Space constraints in compact electronics

- Impedance matching for signal integrity

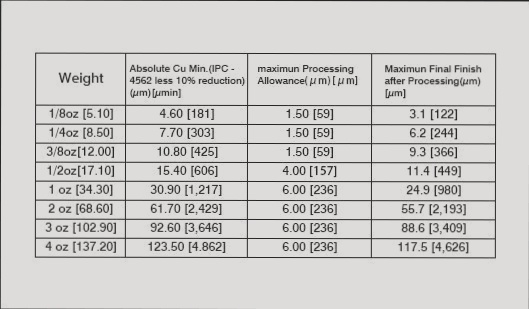

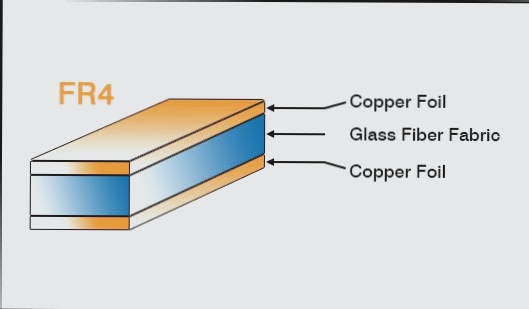

Copper Thickness: Balancing Performance and Cost

When exporting quick-turn PCB prototypes, copper thickness significantly affects both functionality and pricing. The standard ranges are:

“Internal layers typically use 1.4-2.8mm copper, while external layers often require 2-3oz thickness for optimal current handling capacity in high-performance PCB applications.”

Remember that increased copper thickness means:

- Better current-carrying capacity

- Higher manufacturing costs

- More complex processing requirements

PCB Trace Thickness: Preventing Overheating in Export-Grade Boards

For reliable PCB prototypes, trace thickness must accommodate expected current loads without overheating. Our PCB trace width calculator helps designers determine optimal dimensions by analyzing:

- Maximum current requirements

- Temperature rise thresholds

- Copper weight specifications

- Dielectric material properties

How to Specify PCB Thickness for International Clients

When preparing PCB fabrication files for export, include these critical specifications:

- Core and prepreg thickness combinations

- Solder mask application requirements

- Final finished board tolerance (±10% standard)

- Copper weight for each layer

- Impedance control needs

5 Critical Factors for Choosing PCB Thickness

As a trusted PCB assembly manufacturer in China, we recommend evaluating these aspects:

| Factor | Thin PCBs | Thick PCBs |

|---|---|---|

| Mechanical Strength | More fragile | More durable |

| Flexibility | Higher | Lower |

| Space Requirements | Compact devices | Larger enclosures |

| Component Compatibility | Surface-mount | Through-hole |

| Impedance Control | Challenging | Easier to manage |

Why Partner with a Professional PCB Manufacturer for Export?

Choosing the right China PCB fabrication partner ensures you receive boards with:

- Precise thickness tolerances for high-quality PCB prototypes

- Proper material selection for your application

- Expert impedance matching

- Reliable current-handling capacity

- Competitive pricing for export markets

For quick-turn PCB fabrication and assembly that meets international standards, contact our export team today to discuss your project’s specific thickness requirements and receive a competitive quote for global shipping.