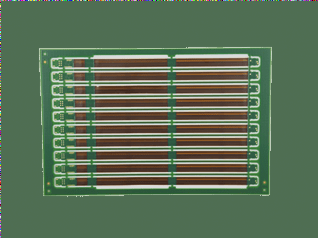

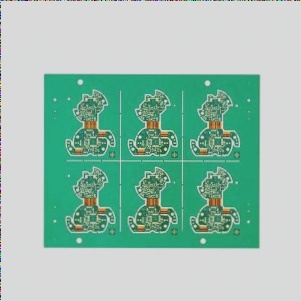

WellCircuits is a technical flexible PCB manufacturer with expterise on Rigid-flex PCBs, once reserved for military and aerospace, now power diverse industries. Transitioning from manual to automated production, these boards offer miniaturization and reliability. Flexible polyimide films connect rigid sections, replacing cables and connectors in tight spaces.We specialize in optimized rigid-flex PCB design, combining RF PCB expertise with advanced manufacturing. Let us help you achieve precision and reliability for your next project.

Rigid-Flex PCB

- 3D design freedom.

- Dynamic possibilities.

- Reduce volume and weight.

- Reliable connection.

- Simplified assembly process.

- Reduce costs.

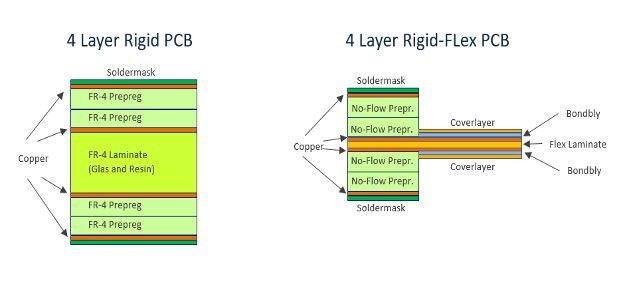

Rigid-Flex PCB Substrates

- Flexible copper-clad laminate.

- Coverlay.

- Non-flowing prepreg.

- Bond ply material.

- Rigid clad material.

Rigid Flex PCB

Rigid-Flex PCBs merge the features of rigid and flexible printed circuit boards to provide dependable compact circuit designs. They allow the creation of intricate 3D designs and complex shapes in flex PCB applications, enabling the achievement of the desired shape for the final product, which renders them perfect for use in smartphones and industrial and aerospace systems. The creation of these PCBs requires strict management of complex manufacturing rules and specialized materials to maintain flexibility and performance during both flex prototype and production phases. Early involvement in the design process and close collaboration with fabricators is essential to address complex design challenges, material selection, and design rules for reliable rigid-flex PCB production.

Polyimide-based flexible PCBs provide essential adaptability for wearable technologies and offer special benefits in condensed circuit layouts. Rigid-Flex PCBs combine rigid boards with flexible segments to deliver both adaptability and strong support. The design of traditional rigid PCBs uses materials such as FR-4 which prevents bending while rigid-flex PCB manufacturing requires flexibility considerations. The integrated design approach and use of flexible materials during production and assembly make rigid-flex PCBs both complex and expensive. The manufacturing process involves multiple intricate steps, including layering, drilling, plating, and testing, which add to the complexity and cost.

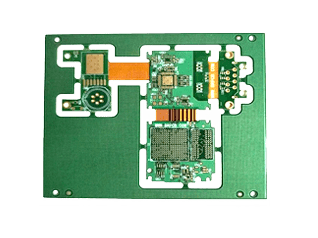

The combination of rigid outer layers and flexible inner layers through copper-plated vias enables rigid-flex PCBs to offer advanced circuit board solutions. Proper layer stackup and careful management of layer counts are critical for achieving mechanical flexibility and maintaining signal integrity in these designs. The design decreases dependency on connectors and wiring harnesses to enhance reliability and component density for large scale rigid-flex PCB applications, especially beneficial in the flex portion. Flex areas, flex sections, and flexible layers are strategically integrated within the stack-up to provide the necessary bending flexibility and electrical performance required for advanced applications.

Advanced drilling techniques used in rigid-flex PCB production maintain precision tolerances of +/- 0.05 mm while enabling intricate mechanical designs that adhere to strict design rules from the beginning. Impedance control and maintaining signal integrity are crucial, as improper design or layer transitions can affect signal quality, leading to performance issues. More complex design rules are required for rigid-flex PCBs compared to rigid PCBs, due to the need to manage bend radii, layer transitions, and material constraints.

Specialized handling processes, together with careful material selection and rigorous inspection, ensure long-term performance and reliability in rigid-flex PCB production. Material constraints play a significant role in determining the flexibility, thermal expansion, and manufacturability of the final product.

During installation, static applications need flexibility but dynamic applications require ongoing flexing throughout operation as seen in flexible PCB implementations. ED copper serves static applications while RA copper works for dynamic applications to maintain durability during flex and rigid-flex PCB manufacturing so PCB portions excel in high-performance tasks. Selecting an appropriate bend radius in flex areas is essential to prevent mechanical failure and ensure the durability of the flex section during repeated flexing.

Consumer electronics such as smartphones and wearables frequently use Rigid-Flex PCBs to demonstrate flexible circuit boards’ adaptable capabilities. These PCB solutions deliver durable and space-efficient designs by overcoming rigid PCB constraints while maintaining proper integration between rigid and flexible circuit board components. Rigid-flex PCBs are especially advantageous in weight sensitive applications, where minimizing size and weight is critical.

The superior flexibility and durability of Rigid-Flex PCBs enables them to endure extreme conditions, making them the preferred option for aerospace and defense applications. They are well-suited for harsh environments, withstanding temperature fluctuations, vibrations, and mechanical stress. The fabrication process of rigid-flex circuit boards meets rigorous industry reliability standards through essential design rule adherence and advanced flex technology deployment for large scale production needs. Heat dissipation is a key challenge in rigid-flex PCB design, as flexible substrates can impact thermal management and device longevity.

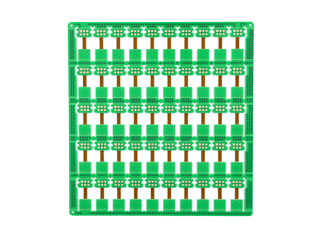

Rigid-Flex PCBs demonstrate their critical role in flex and rigid-flex circuit boards applications through enhanced reliability and space reduction in medical devices such as pacemakers. Precise fabrication and flexibility enable miniaturization and high-density interconnects in flexible sections of flexible-rigid assemblies. The use of multiple layers in rigid-flex PCBs increases design flexibility and functionality for advanced electronic applications.

Rigid-Flex PCBs incorporate rolled annealed copper foil as part of their advanced materials portfolio to deliver both high-density functionality and dynamic flexibility in their design. The development of rigid flex prototypes enables quality flex PCB fabrication with reduced part counts and performance improvements during early design stages. Rigid board technologies, rigid circuit boards, and rigid materials form the foundation of these advanced printed circuit board solutions, enabling the integration of both rigid and flexible elements.

Long-term reliability and performance of rigid-flex PCB solutions are secured through the use of advanced manufacturing techniques like high-reliability materials and precision drilling. Reliability issues, especially in via structures, can be mitigated by using specific construction methods such as air gap configurations, which help meet industry standards and extend the functional longevity of the flex sections.

The market requirement for compact yet dependable devices leads to increased production of Rigid-Flex PCBs which extend their use into rigid board technology and support cutting-edge flexible circuit board designs. The use of multi-layer designs and selective connections in rigid-flex boards improves flexibility and strength and thus meets future electronic requirements for large-scale rigid-flex PCB manufacturing with strategic rigid-flex integration. Compared to traditional PCBs, rigid-flex PCBs offer superior space efficiency, durability, and design versatility.

Rigid-flex PCBs demonstrate superior resilience to mechanical stress and vibrations which allows them to function effectively in demanding PCB fabrication settings, particularly when working with flexible and rigid-flex designs during both design and fabrication stages. The design lowers failure rates leading to extended product lifespans and dependable operation under harsh conditions, which proves essential for rigid components in rigid printed circuit boards while mindful selection of rigid-flex solutions is applied. Layer transition between rigid and flexible sections must be carefully managed, as improper layer transitions can result in impedance mismatches, signal degradation, and mechanical stress.

Rigid-flex PCBs combine rigid and flexible areas to remove connectors and cables and decrease the size and weight of flexible circuit applications. Flex areas and flexible layers are essential for achieving the required mechanical flexibility and electrical performance. Rigid-flex PCBs serve as perfect solutions for compact and lightweight applications within flexible and rigid-flex technology fields during the initial design stages where flexibility is prioritized.

The high reliability of Rigid-Flex PCBs stems from minimized connectors and solder joints, resulting in improved reliability and fewer potential failure points compared to traditional designs, making them an excellent option for rigid-flex solutions in demanding applications during soldering than rigid FR4 boards. These materials survive many bending cycles while delivering dependable performance when exposed to tough environments.

The production of rigid-flex PCBs requires specialized materials and processes which increase both cost and complexity, especially when flex layers must be integrated. The production of rigid-flex PCBs cuts assembly expenses by decreasing both component numbers and manual procedures, which still takes longer than producing rigid boards. Manufacturers like Sierra Circuits are known for their quick-turn capabilities in PCB fabrication and assembly.

Creating rigid-flex printed circuit boards demands adherence to complex design rules as well as meticulous planning to fulfill both mechanical and electrical requirements in PCB design. The production of a rigid flex prototype needs careful consideration of material limitations and layer stacking configurations. Complex design rules compared to rigid PCBs must be followed to ensure mechanical reliability, signal integrity, and manufacturability of the flexible sections.

Types of Flexible Circuits

Flexible circuits are foundational to the advancement of rigid flex technology, offering a range of configurations to address diverse electronic design requirements. Understanding the different types of flexible circuits is essential for engineers and OEMs aiming to optimize rigid flex PCB design for both performance and reliability.

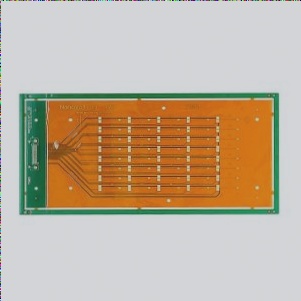

Single-Sided Flex Circuits utilize a single conductive layer on a flexible substrate, making them ideal for straightforward, low-density applications where space savings and flexibility are paramount. These circuits are commonly used in devices that require simple interconnections and must withstand repeated bending without compromising signal integrity.

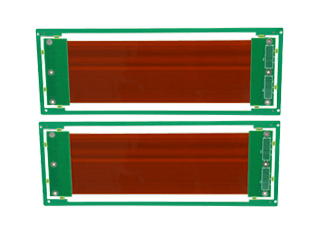

Double-Sided Flex Circuits feature conductive layers on both sides of the flexible substrate, connected by plated through-holes. This configuration supports more complex routing and additional signal layers, making it suitable for applications that demand higher circuit density and improved electrical performance.

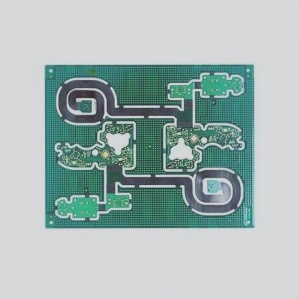

Multi-Layer Flex Circuits incorporate three or more conductive layers, separated by insulating materials. This structure enables the integration of multiple signal layers and power planes, which is critical in advanced rigid flex PCB designs where space constraints and high functionality are required. Multi-layer flex circuits are often found in medical devices and compact aerospace systems, where maintaining signal quality and controlling electromagnetic interference are essential.

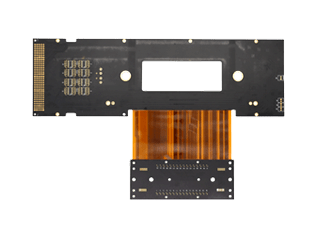

Rigid-Flex Circuits combine rigid and flexible sections within a single assembly, allowing for intricate three-dimensional configurations. Most rigid flex boards consist of rigid areas for component mounting and flexible sections for dynamic movement or tight-space routing. This hybrid approach is particularly valuable in applications that require both mechanical stability and the ability to withstand repeated bending, such as in medical implants or avionics.

Shielded Flex Circuits are designed with additional layers or materials to protect against electromagnetic interference (EMI) and radio-frequency interference (RFI). Shielding is crucial in high-speed or sensitive signal applications, ensuring that the flexible circuit substrates attached to rigid sections maintain optimal signal integrity even in electrically noisy environments.

Tape Automated Bonding (TAB) Circuits are specialized flexible circuits used for high-density interconnections between flexible substrates and integrated circuits. While less common, TAB circuits are essential in applications where space is at a premium and reliable, high-speed connections are required.

When selecting the appropriate type of flexible circuit for a rigid flex PCB, careful consideration must be given to factors such as the desired bend radius, the ability to withstand repeated bending, and the compatibility of materials between rigid and flexible sections. Properly transitioning signal layers between rigid and flexible areas is critical to avoid impedance mismatches and signal degradation. Additionally, controlling electromagnetic interference and managing the assembly process can significantly impact assembly costs and long-term reliability.

By leveraging the unique advantages of each flexible circuit type, designers can address the complex design rules associated with rigid flex technology, ensuring that the final PCB meets the stringent requirements of modern electronic products. Whether the goal is to minimize weight in aerospace applications, enhance reliability in medical devices, or achieve compactness in consumer electronics, understanding the types of flexible circuits is key to successful rigid flex PCB design.

Design Considerations for Rigid-Flex PCBs

Material Selection: Adhesives and Laminates

Modified epoxy film and polyimide laminates serve as essential bonding agents for circuit protection in flex circuits whereas rigid-flex components demand completely separate requirements. The choice of materials for rigid flex PCBs requires an evaluation of mechanical flexibility along with thermal and electrical performance characteristics to maintain design reliability over time.

Layer Configuration: PCB designs may come in single-sided, double-sided, and multi-layered configurations including flex layer options for rigid-flex designs.

Manufacturing rigid-flex PCBs involves creating single-sided, double-sided and multi-layered boards with stackup configurations that extend from four up to eighteen layers for both PCB fabrication and assembly. Multi-layered structures within rigid-flex printed circuit boards boost connectivity while increasing complexity to fulfill varying application demands during the design phase of rigid-flex PCBs.

Trace Width and Spacing decisions remain critical throughout the rigid-flex manufacturing phase.

Maintaining uniform trace width and spacing throughout the PCB design process helps achieve necessary impedance control and signal integrity for rigid-flex PCBs. Reliable performance in high-speed applications of rigid-flex circuit boards results from proper routing and design planning during the early stages of the rigid-flex design process.

Manufacturing Processes

Combining Rigid and Flexible Layers

The combination of rigid outer layers and flexible inner layers through copper-plated vias enables rigid-flex PCBs to offer advanced circuit board solutions. The design decreases dependency on connectors and wiring harnesses to enhance reliability and component density for large scale rigid-flex PCB applications, especially beneficial in the flex portion.

High-Precision Drilling Techniques

Advanced drilling techniques used in rigid-flex PCB production maintain precision tolerances of +/- 0.05 mm while enabling intricate mechanical designs that adhere to strict design rules from the beginning.

Quality Control Measures

Specialized handling processes, together with careful material selection and rigorous inspection,n ensure long-term performance and reliability in rigid-flex PCB production.

Applications of Rigid-Flex PCBs

Static vs Dynamic Applications

During installation static applications need flexibility but dynamic applications require ongoing flexing throughout operation as seen in flexible PCB implementations. ED copper serves static applications while RA copper works for dynamic applications to maintain durability during flex and rigid-flex PCB manufacturing so PCB portions excel in high-performance tasks.

Use in Consumer Electronics

Consumer electronics such as smartphones and wearables frequently use Rigid-Flex PCBs to demonstrate flexible circuit boards’ adaptable capabilities. These PCB solutions deliver durable and space-efficient designs by overcoming rigid PCB constraints while maintaining proper integration between rigid and flexible circuit board components.

Aerospace and Defense Applications

The superior flexibility and durability of Rigid-Flex PCBs enables them to endure extreme conditions making them the preferred option for aerospace and defense applications. The fabrication process of rigid-flex circuit boards meets rigorous industry reliability standards through essential design rule adherence and advanced flex technology deployment for large scale production needs.

Medical Devices Integration

Rigid-Flex PCBs demonstrate their critical role in flex and rigid-flex circuit boards applications through enhanced reliability and space reduction in medical devices such as pacemakers. Precise fabrication and flexibility enable miniaturization and high-density interconnects in flexible sections of flexible-rigid assemblies.

Innovations in Rigid-Flex PCB Technology

Advanced Material Innovations

Rigid-Flex PCBs incorporate rolled annealed copper foil as part of their advanced materials portfolio to deliver both high-density functionality and dynamic flexibility in their design. The development of rigid flex prototypes enables quality flex PCB fabrication with reduced part counts and performance improvements during early design stages.

Enhanced Manufacturing Equipment and Techniques

Long-term reliability and performance of rigid-flex PCB solutions are secured through the use of advanced manufacturing techniques like high-reliability materials and precision drilling.

Industry Trends and Future Developments

The market requirement for compact yet dependable devices leads to increased production of Rigid-Flex PCBs which extend their use into rigid board technology and support cutting-edge flexible circuit board designs. The use of multi-layer designs and selective connections in rigid-flex boards improves flexibility and strength and thus meets future electronic requirements for large-scale rigid-flex PCB manufacturing with strategic rigid-flex integration.

Benefits of Rigid-Flex PCBs

Mechanical Durability

Rigid-flex PCBs demonstrate superior resilience to mechanical stress and vibrations which allows them to function effectively in demanding PCB fabrication settings particularly when working with flexible and rigid-flex designs during both design and fabrication stages. The design lowers failure rates leading to extended product lifespans and dependable operation under harsh conditions which proves essential for rigid components in rigid printed circuit boards while mindful selection of rigid-flex solutions is applied.

Space and Weight Reduction

Rigid-flex PCBs combine rigid and flexible areas to remove connectors and cables and decrease the size and weight of flexible circuit applications. Rigid-flex PCBs serve as perfect solutions for compact and lightweight applications within flexible and rigid-flex technology fields during the initial design stages where flexibility is prioritized.

Reliable Performance

The high reliability of Rigid-Flex PCBs stems from minimized connectors and solder joints which makes them an excellent option for rigid-flex solutions in demanding applications during soldering than rigid FR4 boards. These materials survive many bending cycles while delivering dependable performance when exposed to tough environments.

Challenges in Manufacturing Rigid-Flex PCBs

Cost and Complexity

The production of rigid-flex PCBs requires specialized materials and processes which increase both cost and complexity especially when flex layers must be integrated. The production of rigid-flex PCBs cuts assembly expenses by decreasing both component numbers and manual procedures which still takes longer than producing rigid boards.

Design and Prototyping Difficulties

Creating rigid-flex printed circuit boards demands adherence to complex design rules as well as meticulous planning to fulfill both mechanical and electrical requirements in PCB design. The production of a rigid flex prototype needs careful consideration of material limitations and layer stacking configurations.