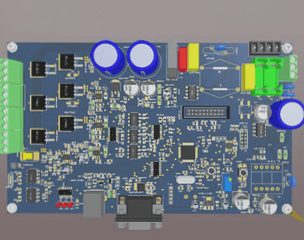

Rigid, Flexible, and Rigid-Flex PCB Types

Circuit boards come in various types, including rigid, flexible, and rigid-flex PCBs. Rigid PCBs are the most common type, while flexible PCBs offer the unique ability to bend. Rigid PCBs typically have thicknesses ranging from 0.2mm to 2.0mm, whereas flexible PCBs are usually around 0.2mm thick, with reinforced soldering areas.

Materials Used in PCBs

Rigid PCBs commonly use materials like phenolic paper laminate, epoxy paper laminate, polyester glass mat laminate, and epoxy glass cloth laminate. On the other hand, flexible PCBs utilize materials such as polyester film, polyimide amine film, and fluorinated ethylene propylene (FEP) film.

Classification by Circuit Layers

PCBs can be categorized based on the number of layers, including single-sided, double-sided, and multi-layer boards. Multi-layer boards are often 4-layer or 6-layer, with more complex designs featuring numerous layers.

Single-Sided Boards

Single-sided PCBs have components on one side and wiring on the other. These boards were commonly used in earlier circuits due to their design constraints, allowing routing on only one side.

Double-Sided Boards

Double-sided boards feature wiring on both sides connected through vias. This design allows for more complex circuits by utilizing both surfaces for wiring, overcoming the limitations of single-sided boards.

Multilayer Boards

Multilayer PCBs incorporate multiple wiring layers to increase the available area for wiring. These boards consist of alternating single- or double-sided layers bonded with insulating material, forming 4-layer or 6-layer boards. The number of layers does not always correspond to the wiring layers, as void layers may be included for thickness control.

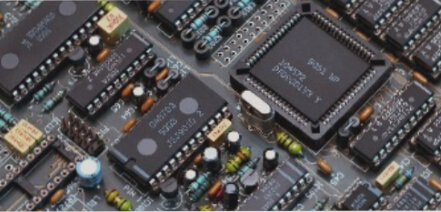

Advantages of PCBs

- High Density: PCBs offer high density, evolving with integrated circuit technology advancements.

- High Reliability: Through rigorous testing, PCBs can operate reliably for extended periods, up to 20 years.

- Design Flexibility: PCB designs can be customized to meet specific requirements, allowing for efficient development and optimization.

Key Advantages of PCBs

- Manufacturability: Advanced management techniques enable efficient mass production of PCBs through standardized, automated processes, ensuring consistent quality.

- Testability: A wide array of testing methods, equipment, and standards are accessible to evaluate the performance and durability of PCB products.

- Assembly Compatibility: PCBs support streamlined component assembly, allowing for automation and large-scale manufacturing. They can also be combined with other parts to create more extensive systems or complete machines.

- Maintainability: With standardized PCB components produced on a large scale, replacing parts for quick system restoration is simple. Other advantages include system downsizing, weight reduction, and improved high-speed signal transmission.