The Impact of Advanced PCB Technology on Electronic Product Development

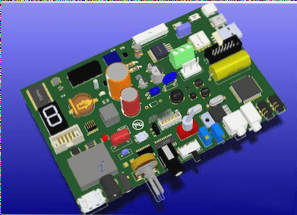

Key Trends in PCB Technology

- Narrower traces

- Smaller and increased trace spacing

- More pronounced height variations

The evolution of PCB technology has accelerated over the past five years, influencing the capabilities and development of electronic products globally.

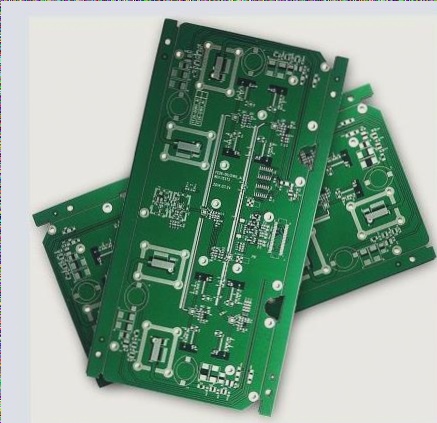

Challenges in PCB Board Industry Instruments

The development of PCB board industry instruments lags due to limitations in light source technology. Inadequate light sources hinder effective illumination and information extraction, impacting backend measurement technologies.

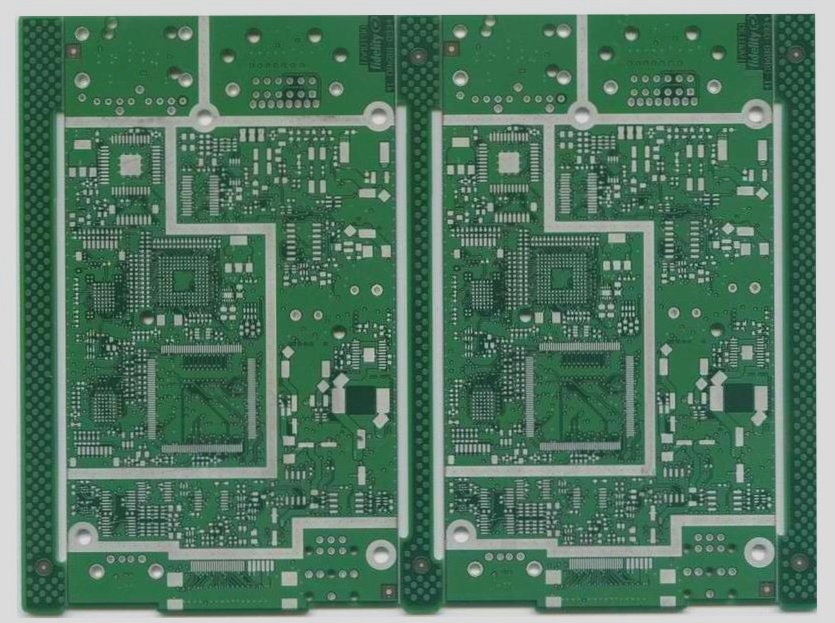

Proposed Solution: Adaptive Ring Light Source

A stable solution for thick dense PCB illumination involves an adaptive ring light source with a fixed-angle design. This design optimizes incident angles and utilizes LED directional light and a diffuser plate for uniform brightness.

Experimental Results

- Artifacts from Ordinary Light Source Illumination

- Impact of Geometric Features on Light Source Design

- Design of Fixed-Angle Adaptive Ring Light Source

Comparisons show that the proposed adaptive light source enhances image quality, ensuring uniformity and sharpness for precise testing and targeted information extraction in image processing.

Conclusion

Enhancing PCB Inspection with Advanced Light Source Design

In the realm of PCB inspection, traditional light sources face limitations when dealing with dense circuitry. A recent study has focused on addressing pseudo-image errors that arise due to low-angle illumination. The research explores how the interplay of geometric and optical factors impacts the design of light sources.

One innovative solution introduced in the study is a purpose-built ring light source with a fixed angle. This new design not only overcomes existing challenges but also improves the illumination of front-end systems and enables more precise extraction of information from PCBs.

The enhancements in image uniformity and contrast achieved through this new light source design have a significant positive impact on back-end processing and information extraction processes. This breakthrough technology shows great promise for widespread adoption in PCB inspection equipment, especially in the realm of line width inspection machines.