Pyrolysis Technology in Waste Circuit Board Recycling

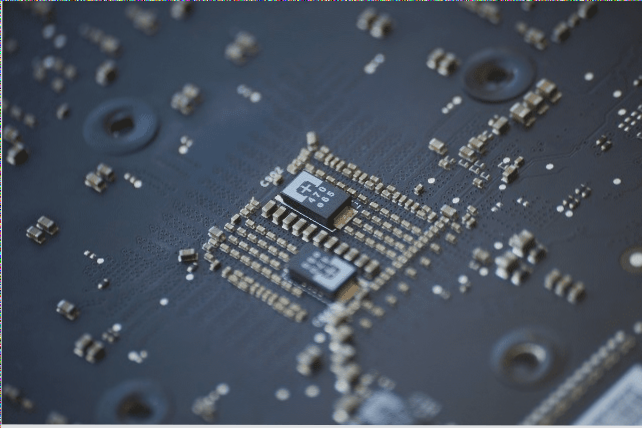

Pyrolysis technology is a cutting-edge method for recycling waste circuit boards. It offers advantages such as larger crushing particle sizes and lower energy consumption, making it a more promising approach compared to other methods.

Efficient Waste Treatment Solution

Pyrolysis technology plays a crucial role in the recycling of waste circuit boards. Ongoing research into its fundamental principles and the development of pyrolysis equipment are paving the way for it to become a leading method for recycling circuit boards from discarded electrical appliances.

Challenges in Bromine-Containing Products Analysis

Current research on measuring bromine-containing products from circuit board pyrolysis is mainly qualitative. Accurate quantitative analysis of specific bromine compounds remains a challenge, hindering a comprehensive understanding of the transformation and migration of bromine-containing flame retardants during the pyrolysis process.

Environmental Impact and Breakthroughs

Researchers are making strides in eliminating bromine-containing pollutants through pyrolysis technology. Inappropriate recycling methods can lead to harmful emissions, posing risks to the environment and processing equipment. Understanding the transformation of flame retardants is crucial for effective debromination and pollution control.

Resource Recovery and Pollution Prevention

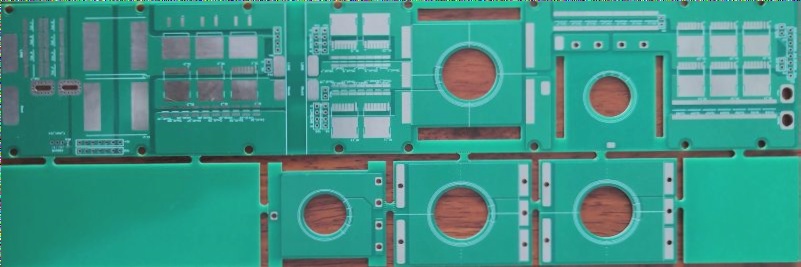

The pyrolysis process captures gas and oil from circuit boards, leaving behind metal and glass fiber residues. These residues can be separated and recovered using physical methods, preventing toxic gas release and ensuring environmental safety. While current recycling methods focus on precious metal recovery, addressing non-metallic components is essential to reduce secondary pollution and promote sustainable waste management.