Preventing PCB Board Deformation: Causes and Solutions

Deformation During PCB Processing

Deformation in PCBs can be attributed to thermal and mechanical stress encountered during processing. Thermal stress arises during pressing, while mechanical stress occurs during stacking, handling, and baking.

Incoming Copper-Clad Laminate

During the pressing process, variations in curing speed and resin curing degree can lead to deformation in copper-clad laminates. The dynamic viscosity of the resin and temperature variations across the hot plate play crucial roles in this process.

Pressing

PCB pressing generates thermal stress due to material and structural differences. The stress is relieved during subsequent processes like drilling, shaping, or grilling, potentially causing board deformation.

Baking Process of Solder Mask, Characters, etc.

Exceeding the glass transition point of materials during the curing process can make the board elastic and prone to deformation under its weight or airflow in the oven.

Hot-Air Solder Leveling

Thermal stresses develop during the heating and cooling stages of solder leveling, leading to microscopic strain and overall deformation in the PCB.

Storage

Improper storage, including tightness adjustment of racks and stacking of boards, can result in mechanical deformation, especially in thinner boards.

Prevention of PCB Warpage and Deformation

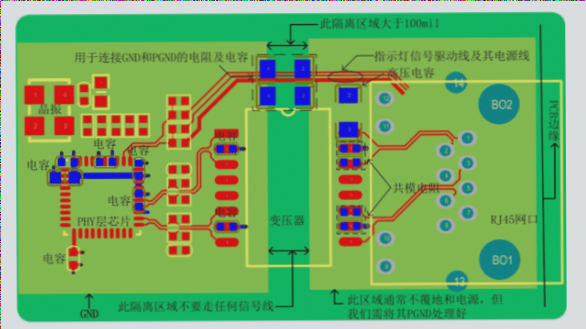

Warpage can disrupt the production process and subsequent operations. Symmetrical arrangement of interlayer prepregs is crucial in minimizing warpage after pressing.

- Engineering Design: Symmetrical arrangement of interlayer prepregs is essential to prevent warpage.

PCB Board Warpage Prevention Techniques

- Ensure Both Core and Prepreg are from the Same Supplier

- Balance Circuit Pattern Areas on A-Side and B-Side

- Dry the Board Before Cutting to Remove Moisture

- Consider Warp and Weft Direction of the Prepreg

- Relieve Stress After Lamination to Prevent Warping

- Straighten Thin Boards During Electroplating

- Cool the Board Properly After Hot-Air Leveling

- Treat Warped Boards with Baking and Pressing

It is crucial to follow these steps to prevent PCB warping issues. Not adhering to these anti-warping measures may result in unusable boards that need to be scrapped.

PCB Board Warpage Standards

For PCB warpage standards, refer to IPC-A-600G, Section 2.11 (Flatness Standard). The distortion or bowing for boards with surface-mounted components should not exceed 0.75%, while other types of boards should not exceed 1.5%. The testing method is outlined in IPC-TM-6502.4.22.