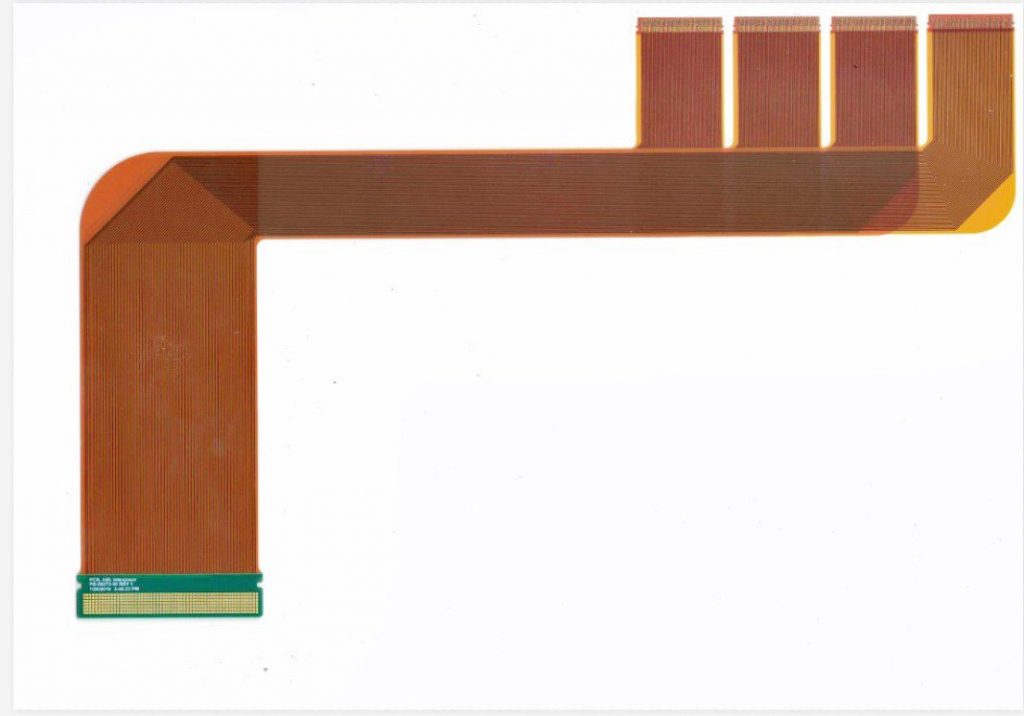

Quick Turn RIGID-FLEX PCB Prototyping in Modern Electronics

In today’s fast-paced electronics industry, rapid PCB prototyping has become a game-changer, enabling companies to accelerate innovation in flex and rigid-flex PCB designs, reduce time-to-market, and stay competitive. This article highlights the importance of rapid PCB prototyping and its key benefits in modern printed circuit board manufacturing, including quick-turn flex PCB and rigid flex printed applications.

I The Importance of Quick Turn PCB Prototyping

Accelerating Innovation

Rapid PCB prototyping allows engineers to create and refine flexible PCB designs at unprecedented speeds, reducing lead times from weeks to days or even hours, especially for quick-turn prototypes. This capability is crucial for companies to stay ahead in competitive markets, quickly iterate designs of rigid-flex PCBs, and drive technological innovation in rigid-flex PCB manufacturing.

Shortening Time-to-Market

Manufacturers like WellCircuits can produce up to six-layer PCBs within 24 hours, with PCB capabilities extending to 64 layers and precision levels of 0.05 mm, including flex PCBs and rigid flex PCBs. This efficiency directly addresses the critical time pressures associated with product launches, enabling companies to introduce quick-turn rigid flex PCBs more quickly and capitalize on market opportunities.

Ensuring Quality and Reliability

Despite the focus on speed, rapid PCB prototyping maintains high quality standards, especially for flex and rigid-flex PCBs, ensuring timely turnaround times. Each PCB undergoes rigorous testing, including Automated Optical Inspection (AOI) and Electrical Testing (E-Test), to ensure reliability and compliance with IPC Class 2 or 3 standards for flexible PCBs. This ensures that prototypes meet high-performance and long-life requirements, particularly for critical applications in rigid-flex circuits.

Cost Efficiency

By streamlining production processes, rapid PCB prototyping reduces both direct manufacturing costs and indirect time-related costs associated with flex and rigid-flex PCB fabrication, showcasing the benefits of flex. It minimizes the risk of design errors and rework, further enhancing cost-effectiveness in the production of flexible printed circuit boards and rigid PCBs.

II. Technical Advantages of Rapid PCB Prototyping

Advanced Manufacturing Technologies

Rapid PCB prototyping leverages cutting-edge technologies such as laser printing and 3D printing to enhance precision and efficiency in the manufacturing processes of polyimide flex materials and flex PCBs. These technologies enable the production of complex, multi-layer PCBs with hybrid materials like FR4 and Rogers, meeting the demands of modern electronics and aerospace applications for rigid-flex printed circuit boards.

Innovative Materials

A wide range of flexible materials, including FR4, Teflon, Rogers, and aluminum, are used to meet diverse design requirements for state-of-the-art rigid-flex PCBs. Advanced surface finishes like ENIG and immersion tin/silver ensure high-quality and reliable PCB performance, particularly in state-of-the-art manufacturing facilities.

Artificial Intelligence and Automation

AI-driven Design Rule Check (DRC) systems detect potential defects with high accuracy, reducing design errors in rigid flex printed circuit boards. Automated inspection processes like AOI and E-Test ensure consistent quality control, further enhancing production efficiency for flex circuits and rigid circuit boards.

Robust CAD/CAM Software

Advanced CAD tools with DRC functions enable early detection of design issues in multilayer quick-turn rigid flex PCBs, ensuring optimal functionality and manufacturability for flexible circuits. These tools support complex design creation with high precision, particularly for quick-turn flex PCBs and multilayer flexible circuits.

III. Industry Applications

Industrial Sector

Rapid PCB prototyping is used in automated equipment and control systems, enabling quick turn rigid flex PCB testing and optimization of designs to meet industrial reliability standards for flex and rigid-flex PCBs.

Medical Device Manufacturing

Rapid prototyping in the medical device industry allows for quick development and validation of high-reliability flex PCBs for critical devices like pacemakers and defibrillators, ensuring they meet stringent aerospace standards.

Consumer Electronics

For consumer electronics, rapid PCB prototyping helps manufacturers quickly develop and test new printed circuit boards, enabling faster time-to-market and meeting consumer demands for high-performance devices.

IV. Choosing the Right PCB Manufacturer

Quality Control System

Ensure the manufacturer has a robust quality control system compliant with ISO and IPC standards to guarantee high-quality rigid circuit boards, particularly for flex PCB design and rigid flex circuits.

Rapid Manufacturing Capability

Choose a circuit board manufacturer with rapid prototyping capabilities to reduce turnaround times and accelerate product development for rigid flex PCBs.

Instant Quotation and Project Management

Select a flex PCB manufacturer offering instant quotations for PCB services to streamline project management and improve efficiency in rigid-flex PCB solutions.

Industry Certifications and Compliance

Consider manufacturers with certifications like AS9100D, ISO 9001:2015, and RoHS compliance to ensure adherence to industry standards for rigid flex PCBs.

Advanced Manufacturing Technology and Customization Capabilities

Evaluate the manufacturer’s ability to handle advanced PCB assembly technologies and offer customization options to meet specific stackup design needs for rigid-flex printed circuit boards.

In conclusion, rapid PCB prototyping is essential for modern electronics development, particularly in the realm of quick-turn PCBs, flexible PCBs, and rigid flex printed circuits. It accelerates innovation, reduces time-to-market for quick-turn PCBs, ensures quality, and enhances cost efficiency in rigid and flexible designs, particularly using polyimide material. By selecting a reliable manufacturer with advanced capabilities, companies can fully leverage the benefits of rapid PCB prototyping to stay competitive in the fast-paced electronics industry, especially for rigid-flex boards.

| Well Circuits supports flex circuits in harsh operating conditions, offering materials with waterproof, moisture-proof, shock-proof, high-temperature resistance, and corrosion resistance properties, showcasing the benefits of flex. As you delve into the world of flexible PCBs, trust our seasoned engineers to guide you through efficient, quick-turn PCB assembly services, ensuring fast turnaround. design and manufacturing Processes for flex, rigid-flex, and HDI-flex PCBs—all crafted within the U.S., emphasize the importance of quality in quick turn prototype production. Experience unparalleled quality, innovation, and localized manufacturing with Well Circuits, a leading flex and rigid-flex PCB manufacturer. |