AI Smart Bracelet Manufacturing: Complete Guide to Circuit Board Production

“Precision-engineered circuit boards form the backbone of high-performance wearable technology, requiring exacting manufacturing standards for global markets.”

Introduction to AI-Powered Smart Bracelets

The AI smart bracelet represents the cutting edge of wearable health technology, combining sophisticated sensors with advanced data processing capabilities. As a leading smart bracelet manufacturer in China, we specialize in producing medical-grade wearables that meet international export standards for accuracy and reliability.

Core Components of Premium Smart Bracelets

Essential Hardware Elements

- Compact ergonomic design (typically 40-50mm diameter, 10-15mm thickness)

- High-resolution OLED/LCD touch displays

- Multi-sensor arrays for comprehensive health tracking

Advanced Monitoring Capabilities

Our best smart bracelets for health monitoring feature:

- Military-grade motion tracking with 99% step counting accuracy

- Medical-grade PPG optical heart rate sensors

- Advanced sleep stage analysis technology

- SpO2 monitoring for blood oxygen levels

Smart Bracelet PCB Manufacturing Process

Step-by-Step PCBA Production

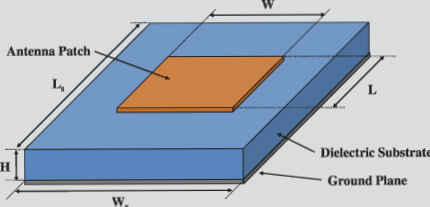

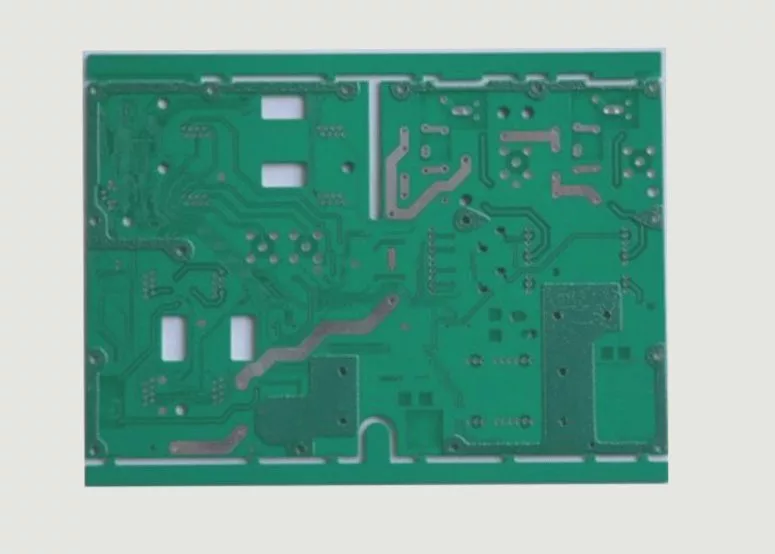

- Material procurement: High-quality FR4 substrates and RoHS-compliant components

- PCB fabrication: 6-layer HDI boards with 0.1mm minimum trace width

- SMT assembly: High-precision component placement (±0.025mm accuracy)

- Reflow soldering: Nitrogen atmosphere for oxidation-free joints

- Functional testing: Automated optical inspection (AOI) and flying probe tests

Critical Design Considerations

- How to choose a reliable PCB manufacturer in China: Verify ISO 13485 medical device certification

- Ultra-low power consumption designs (typically <5mA in sleep mode)

- EMI/EMC shielding for wireless communication stability

- Waterproof conformal coating (IP68 rating achievable)

Rigorous Quality Assurance Protocol

Comprehensive Testing Procedures

- Continuity testing (500V Hipot withstand voltage)

- Current consumption analysis (including peak load scenarios)

- Sensor calibration against medical reference devices

- Bluetooth 5.2 range and interference testing

- Environmental stress testing (-20°C to +60°C operational range)

Export-Ready Manufacturing Solutions

As a trusted smart bracelet supplier for international trade, we provide:

- CE/FCC/IC certification support

- Multi-language app compatibility

- Custom branding and packaging solutions

- DDP shipping arrangements worldwide

Conclusion: Partnering for Wearable Tech Success

Understanding how AI smart bracelets are manufactured helps global buyers make informed sourcing decisions. Our vertically integrated production facility combines:

- State-of-the-art SMT lines (50,000 components/hour capacity)

- Class 10000 cleanroom for medical device production

- In-house reliability testing laboratory