PCB vs PCBA: Understanding the Core Differences for Global Export Businesses

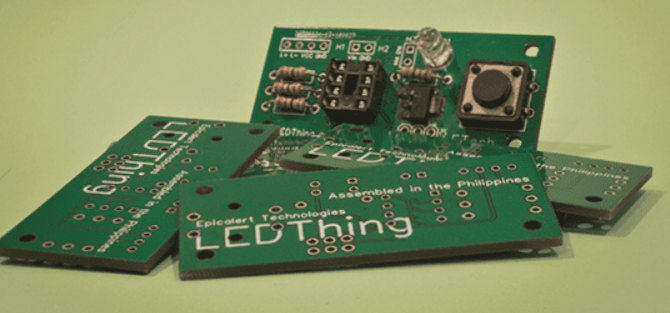

What Is a Printed Circuit Board (PCB)? The Foundation of Modern Electronics

In today’s global electronics manufacturing landscape, Printed Circuit Boards (PCBs) serve as the backbone of virtually all electronic devices. As a leading PCB manufacturer in China, we understand international buyers need clear technical distinctions when sourcing components.

“PCBs revolutionized electronics by replacing point-to-point wiring with integrated conductive pathways, enabling mass production of reliable devices.”

Key Characteristics of PCBs

- Substrate Materials: Fiberglass (FR4), ceramic, or flexible polymers

- Conductive Layers: Copper traces with tin-lead or gold plating

- Primary Function: Mechanical support and electrical connectivity

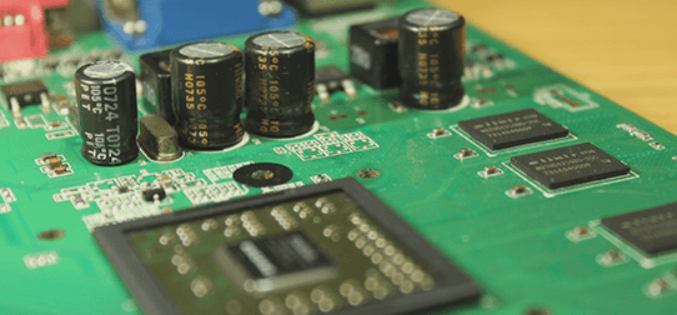

What Is PCBA? The Complete Circuit Solution

Printed Circuit Board Assembly (PCBA) represents the next evolutionary stage – a fully populated board ready for integration into end products. For businesses seeking turnkey electronic manufacturing services, understanding PCBA is crucial.

PCBA Manufacturing Processes

- Surface-Mount Technology (SMT): Best for high-density, compact designs

- Through-Hole Technology (THT): Ideal for high-reliability applications

- Mixed Technology: Combines both methods for complex assemblies

Critical Differences: PCB vs PCBA for International Buyers

Structural Comparison

| Feature | PCB | PCBA |

|---|---|---|

| Components | Bare board only | Fully populated with components |

| Conductivity | Potential pathways only | Functional electronic circuits |

| Testing Requirements | Basic continuity checks | Full functional testing |

Global Market Applications: Where to Use PCB vs PCBA

PCB Applications

- Prototype development for new electronics

- Custom circuit designs requiring specialized components

- Educational and research purposes

PCBA Applications

- High-volume consumer electronics manufacturing

- Medical device production requiring certified assemblies

- Automotive and aerospace systems

Choosing Between PCB and PCBA for Your Export Business

When evaluating how to source electronic components from China, consider these factors:

- Design complexity: Simple circuits may only need PCBs

- Volume requirements: PCBA becomes cost-effective at scale

- Testing capabilities: PCBA providers offer complete quality assurance

- Supply chain management: PCBA simplifies component procurement

Future Trends in PCB/PCBA Technology

The global PCB market is evolving with these innovations:

- High-density interconnect (HDI) technology

- Flexible and rigid-flex circuit solutions

- Embedded component technology

- Environmentally friendly manufacturing processes

Why This Matters for Exporters

Understanding these differences helps businesses:

- Select the best PCB manufacturer for industrial applications

- Optimize electronics sourcing strategies

- Navigate international quality standards and certifications

For companies looking to import electronic components from Asia, recognizing the distinction between bare boards and complete assemblies ensures you procure exactly what your production line requires.