PCB Component Placement Solutions

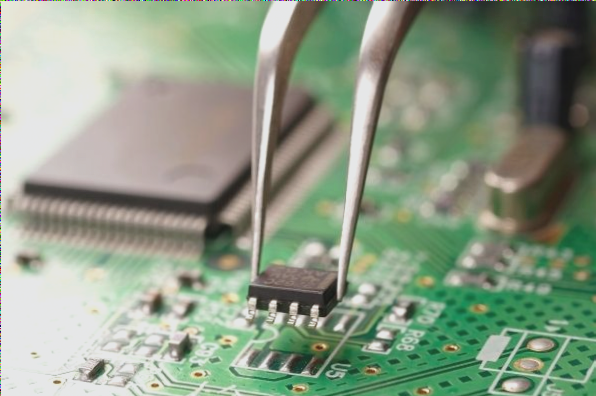

To achieve the required PCB placement accuracy and accommodate various components, the following commonly used solutions are employed:

Solution 1: Multi-Chip Placement

In this method, multi-chip flexible printed circuit boards (FPCs) are positioned on a pallet using a positioning template to ensure stability during the SMT placement process.

Scope of Application:

- Component Types: Ideal for chip components larger than 0603 and QFQs with lead pitches of 0.65mm or more.

- Number of Components: Each FPC typically contains a few to a dozen components.

- Placement Accuracy: Moderate level of accuracy is sufficient.

- FPC Characteristics: FPC is slightly larger than the area without components, with MARK marks and positioning holes for alignment.

FPC Fixing Process:

- CAD data used to create a high-precision positioning template.

- Positioning pins on the template match FPC’s positioning holes.

- Pallets fabricated with minimal warpage material like FR-4.

- Pallet placed on the template’s positioning pins before SMT process.

Minimizing storage time between fixing the FPC on the pallet and starting the soldering process is crucial for accuracy.

Solution 2: High-Precision Placement

Involves fixing FPCs onto a high-precision positioning pallet for optimal placement during SMT assembly.

Summary and Key Insights:

- Solution 1: Ideal for medium placement accuracy and small to moderate component numbers.

- Solution 2: Recommended for higher precision placement.

- High-quality materials and low warpage essential for both solutions.

Minimizing time between FPC fixation and SMT processes is crucial for high-quality results.

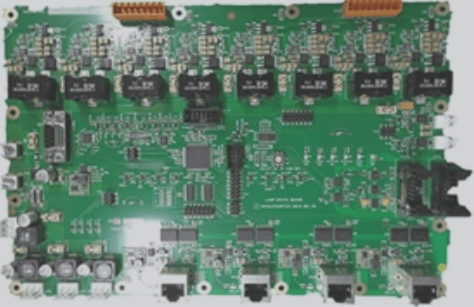

Scope of Application

A. Component Types: Compatible with conventional components and QFP components with less than 0.65mm pitch.

B. Number of Components: Designed for applications with more than a dozen components, suitable for medium to high-density PCB designs.

C. Placement Accuracy: Ensures high precision, especially for components like QFP with up to 0.5mm pitch.

D. FPC Characteristics: FPCs have large surface areas, positioning holes, and MARK marks for optical alignment.

FPC Fixing Mechanism

A. FPC Positioning on Pallets: FPC placed on a highly precise pallet with two pins for accurate positioning.

High-Precision Placement and Process Considerations

A. FPC Orientation: Careful planning of FPC placement direction ensures proper soldering and minimizes solder joint risks.

B. Moisture Sensitivity: Consideration needed for moisture-sensitive components during the assembly process.

Important Considerations for Flexible Printed Circuits (FPCs)

- Moisture Absorption: Similar to plastic SMD components, FPCs can absorb moisture, leading to warping and delamination under high temperatures. It is crucial to dry FPCs at 125°C for 12 hours before use.

- Solder Paste Storage: Solder paste is sensitive to temperature and humidity. Store it between 4°C-8°C and allow it to reach room temperature for 8 hours before use to prevent soldering defects.

Environmental Requirements

- Temperature and Humidity: Maintain a constant temperature of 20°C with humidity below 60% for optimal solder paste printing results.

Component and Hole Wall Processing

- Chemical Corrosion vs. Polishing: Consider using a local chemical polishing method to improve hole wall smoothness over traditional chemical corrosion.

- Laser Processing: Laser methods offer precise results with smooth hole walls, ideal for fine-pitch components like QFPs with 0.3mm pitch.

Printing Parameters

- Squeegee Type and Hardness: Use polyurethane flat squeegees with a hardness of 80-90° for FPC printing.

- Squeegee Angle: Maintain a squeegee angle between 60°-75° for optimal paste deposition.

- Printing Direction: Printing from left to right or front to back ensures even paste distribution on QFP pads.

- Printing Speed: Control printing speed between 10-25mm/s to avoid uneven paste distribution.

- Printing Pressure: Adjust pressure between 0.1-0.3 kg/cm for proper paste application.

Reflow Soldering Process

- Hot Air Convection Infrared Reflow: Use hot air convection infrared reflow soldering for even heat distribution and consistent results.

- Temperature Profile Testing: Calibrate reflow soldering temperature profiles using test pallets with components to ensure quality soldering.

- Temperature Curve and Conveyor Speed: Optimize temperature zones and control reflow time to approximately 3 minutes for reliable soldering results.

By adhering to these guidelines, you can achieve high-quality soldering for FPC-based assemblies, guaranteeing optimal performance in various applications.