-

-

-

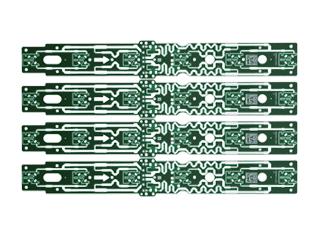

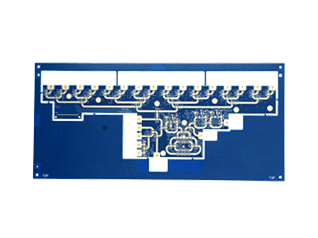

- Medical PCB

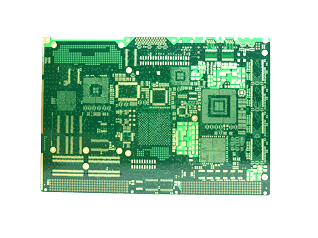

8-layer high-frequency mixing pressure mechanical blind hole PCB

Rated 0 out of 5Read more -

-

The medical and healthcare PCB products we provide

WellCircuits fabricates and assembles medical PCBs that are suitable for a broad array of medical devices like:

- Medical imaging devices

- Medical monitoring systems

- Robotic surgery

- Radiotherapy or radiation therapy

- Blood press monitor

The testing standards we follow for medical PCBs

We conduct continuous testing at every step of the production process to ensure the reliability of the medical circuit boards.

- Automatic optical inspection (AOI): AOI takes pictures of the PCB by using one 2D camera and/or two 3D cameras. The image captured is then checked against the schematic. If the circuit does not conform to the schematic, the board goes through manual inspection.

- Solderability tests ensure that the solder joints are safe.

- Testing for ionic contamination: Ionic contamination testing is carried out to find Ionic residues that result from the process of fabrication and soldering.

- Peel Test: Determines the measure of strength needed to peel the laminate off the board circuit.

- Micro-sectioning analysis The examination is conducted to assess the condition on the circuit board and to detect internal faults.

- Test of flying probes: The test probe is moved from test points to different test points and then checked for shorts, openings, and other issues.

- Reflectometer in the time-domain (TDR): TDR impedance measurements are vital to verify the integrity of the signal. It also monitors for electrical irregularities in connectors or another electrical pathway.

Medical PCB: The Products We Provide for Healthcare

WellCircuits fabricates and assembles medical PCBs that are suitable for a broad array of medical devices like:

Medical imaging devices

Medical monitoring systems

Robotic surgery

Radiotherapy or radiation therapy

Blood press monitor

WellCircuits specializes in medical PCB assembly, utilizing specialized manufacturing processes and strict quality assurance protocols in compliance with standards such as ISO 13485 to ensure the highest reliability for medical applications.

WellCircuits’ medical printed circuit boards are used in life saving devices such as life support ventilators and ultrasound machines, as well as other medical devices including small medical devices for wearable and implantable applications. Healthcare specialists rely on such devices, including air respirators and monitoring systems, which are powered by advanced PCB technologies. WellCircuits produces high quality medical pcb and medical grade PCBs, which are essential for ensuring the safety, reliability, and compliance of medical devices. This includes multilayer PCBs with miniature components and advanced electronic components to meet the stringent requirements of the medical sector. A multilayer pcb is a complex, high-density board with multiple layers of substrates and conductive materials, providing advanced functionality for sophisticated medical devices such as CT scanners and MRI machines. Thermal management and the use of reliable conductive material are critical in ensuring the safety and performance of every medical device PCB. As leading PCB manufacturers, WellCircuits utilizes surface mount technology and other advanced PCB technologies to support a wide range of medical applications in the medical field.

Introduction to Medical PCBs

Medical Printed Circuit Boards (PCBs) are foundational to the operation and advancement of modern medical devices. These specialized circuit boards are engineered to perform reliably in the demanding environments of healthcare, where precision and safety are paramount. From diagnostic equipment and monitoring systems to therapeutic instruments and life saving devices, medical printed circuits are integral to a wide range of medical equipment. The medical industry depends on these high-performance PCBs to ensure that devices function accurately and consistently, supporting healthcare professionals in delivering effective patient care. As technology continues to evolve, the role of medical PCBs in enabling innovation and improving outcomes in the medical field becomes increasingly significant.

Medical Industry Overview

The medical industry is at the forefront of technological advancement, continually seeking new ways to enhance patient care and improve health outcomes. Central to this progress are medical devices that rely on sophisticated printed circuit boards (PCBs) to function with precision and reliability. From diagnostic equipment and monitoring systems to therapeutic instruments, medical equipment is becoming increasingly complex, demanding the highest standards of safety and performance. As a result, medical device manufacturers must work closely with experienced PCB manufacturers who understand the unique requirements of the medical industry. The use of medical grade PCBs is essential in ensuring that various medical devices operate flawlessly, supporting healthcare professionals in delivering accurate diagnoses and effective treatments. In this dynamic environment, the quality and reliability of medical PCBs are not just important—they are critical to the success of the entire healthcare ecosystem.

Medical PCB Applications

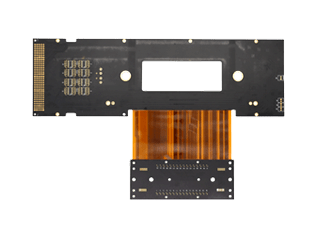

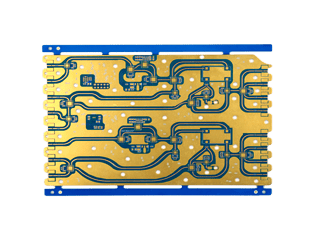

Medical PCBs are at the heart of a vast array of medical devices and equipment, supporting everything from diagnostic imaging to real-time patient monitoring. In the medical industry, these high-quality printed circuit boards are essential for ensuring the performance, reliability, and safety of healthcare technology. Medical PCB applications span numerous specialties, including cardiology, neurology, oncology, and more, powering devices such as pacemakers, MRI machines, infusion pumps, and advanced patient monitoring systems. The growing demand for portable and wearable medical devices has accelerated the adoption of flexible and rigid flex PCBs, enabling the development of compact, lightweight, and highly reliable smart devices for continuous patient care. As medical technology evolves, the role of medical PCBs in supporting innovative monitoring systems and life-saving equipment continues to expand, driving improvements in patient outcomes and healthcare delivery.

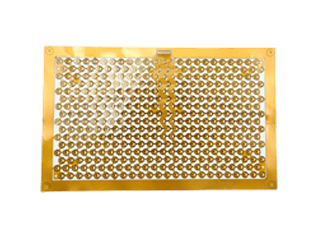

Types of Medical PCBs

The medical industry relies on several types of PCBs, each engineered to meet the specific demands of various medical devices. Rigid PCBs are widely used in applications that require high reliability and structural stability, such as medical imaging equipment and patient monitoring systems. Flexible PCBs, crafted from flexible materials, are ideal for wearable devices and implantable devices, where space constraints and the need for flexibility are paramount. Rigid-flex PCBs combine the durability of rigid boards with the adaptability of flexible circuits, making them perfect for complex medical device designs that require both stability and movement, such as in advanced monitoring systems and surgical instruments. High-density interconnect (HDI) PCBs are utilized in devices that demand high-speed signal transmission and intricate circuitry, including MRI and CT scanners. Each type of medical PCB is designed to deliver high reliability and performance, ensuring that medical device manufacturers can meet the stringent requirements of the healthcare sector.

The Role of PCBs in Medical Devices

Printed circuit boards are the backbone of modern medical devices, enabling the precise control and regulation of electronic functions essential for patient care. In medical equipment, PCBs ensure that devices operate accurately and reliably, supporting critical applications from diagnostic imaging to life support. The development process for medical device PCBs involves meticulous attention to electrical design, manufacturing quality, and regulatory compliance. Medical PCBs must adhere to rigorous standards set by organizations such as the Food and Drug Administration (FDA) and ISO, ensuring patient safety and device reliability. As medical devices become more sophisticated, the role of PCBs in enabling advanced features and maintaining high standards of safety and performance becomes even more vital, supporting healthcare professionals in delivering the best possible care.

Designing Medical Grade PCBs

Designing medical grade PCBs is a meticulous process that requires a deep understanding of both technical and regulatory requirements. Medical device manufacturers must prioritize signal integrity, thermal management, and the selection of high-quality materials to ensure the reliability and safety of their products. Every aspect of the design must comply with stringent medical industry standards, including those set by the Food and Drug Administration (FDA) and international regulatory bodies. Advanced pcb technologies are employed to address the unique challenges of medical applications, such as miniaturization, high reliability, and resistance to electromagnetic interference. By adhering to best practices in PCB design and leveraging the latest innovations, manufacturers can produce medical grade PCBs that meet the rigorous demands of the medical industry and support the development of next-generation healthcare solutions.

PCB Manufacturing Process

The manufacturing process for medical PCBs is characterized by strict quality control and adherence to industry standards at every stage. PCB manufacturers begin with a detailed design phase, followed by precision fabrication using high-quality materials and advanced techniques such as surface mount technology (SMT). During assembly, components are placed and soldered with exacting accuracy to ensure optimal performance. Rigorous testing, including automated optical inspection (AOI) and functional verification, is conducted to detect any defects or inconsistencies. Throughout the process, compliance with process qualification standards and regulatory requirements, such as ISO 13485, is maintained to guarantee the safety, reliability, and traceability of every medical device PCB. This commitment to quality control ensures that medical PCBs meet the high expectations of the healthcare industry.

The testing standards we follow for medical devices and PCBs

Quality assurance is a top priority at WellCircuits, with all processes adhering to strict medical industry standards and a comprehensive quality management system to ensure the safety, reliability, and compliance of every medical PCB.

We conduct continuous testing at every step of the production process to ensure the reliability of the medical circuit boards.

Automatic optical inspection (AOI): AOI takes pictures of the PCB by using one 2D camera and/or two 3D cameras. The image captured is then checked against the schematic. If the circuit does not conform to the schematic, the board goes through manual inspection.

Solderability tests ensure that the solder joints are safe.

Testing for ionic contamination: Ionic contamination testing is carried out to find Ionic residues that result from the process of fabrication and soldering.

Peel Test: Determines the measure of strength needed to peel the laminate off the board circuit.

Micro-sectioning analysis The examination is conducted to assess the condition on the circuit board and to detect internal faults.

Test of flying probes: The test probe is moved from test points to different test points and then checked for shorts, openings, and other issues.

Reflectometer in the time-domain (TDR): TDR impedance measurements are vital to verify the integrity of the signal. It also monitors for electrical irregularities in connectors or another electrical pathway.

We follow rigorous process qualification standards to ensure high accuracy and reliability in every pcb assembly. A detailed quality management system is implemented to comply with international regulations, such as ISO 13485:2016, and to manage hazardous materials safely throughout the production process.

What can we do to ensure your highest reliability requirements for medical grade PCBs by providing 100% traceability

As per IPC-6012 class 2 and Class 3, we design and build basic, advanced micro and standard boards that have high quality and precision. The advanced boards have UL Standard 94 V-0 for flammability. We offer the following documentation and certifications:

Certificate of conformity

Specifications on the material

First Article Inspection Report

Reflow Profile Copy (included in the article that begins)

Requirements for photos

IPC J-STD-001E

Documentation of all calibrated tools employed during the manufacturing process.

Report of AOI or visually inspected report

Testing in circuits or using a flying probe Report

The report of the Ionic Cleansing Test

All medical electrical equipment is designed and manufactured in compliance with international standards to ensure safety and reliability. Traceability begins at the initial schematic design stage, ensuring that every step of the process is documented and controlled.

The following guidelines are followed which help us create high-quality and reliable medical PCBs to the medical and healthcare business.

IPC 6011 Specification for performance of classes 1, class 2, and PCBs of class 3

IEC 60601-1 The general requirements to ensure fundamental safety and performance of electrical medical equipment

IEC 60601-1-2 Definition of electromagnetic needs (EMI as well as EMF) in medical PCBs

ISO 1335:2016: Provides quality management systems for medical equipment

We provide DFM/DFA check-ups on each medical printed circuit board.

We focus on DFM as well as DFA analysis to prevent problems and provide an internal quality inspection system that guarantees no-defect boards. We also offer engineering assistance to determine if the product is performing in the way you expect and is IPC class 3 certified if you choose to use the IPC class 3.

Comprehensive electrical testing of medical PCBs

We are not compromising in terms of quality. We adhere to the strict fabrication guidelines that medical boards must meet, which means continuous testing at every step of the production process, including cross-sections and AOI tests, BGA X-ray, flying probes, and various other electrical tests.

Fantastic and all assembly within one building

Miscommunication between the separate factories and assembly facilities can lead to delays in delivery and errors in the board. A PCB manufacturer who doesn’t manage assembly will not run DFA checks to verify that the board will be assembled properly. Only one vendor is accountable.

Comparison to Consumer Electronics

While both medical PCBs and consumer electronics rely on advanced circuit board technology, the requirements for medical device manufacturers are far more stringent. In consumer electronics, the focus is often on cost efficiency and rapid production cycles. In contrast, medical PCBs must meet rigorous safety, reliability, and quality standards, as even minor failures can have serious consequences for patient health. Medical device manufacturers are required to use only the highest quality components, implement comprehensive testing protocols, and comply with strict regulatory guidelines, including those from the FDA and ISO. These stringent requirements make the design and production of medical PCBs more complex, time-consuming, and costly than those for consumer electronics, but they are essential to ensuring the safety and efficacy of medical electrical equipment.

Choosing a PCB Manufacturer

Selecting the right PCB manufacturer is a pivotal decision for medical device manufacturers aiming to deliver safe, reliable, and innovative products. The medical industry imposes strict requirements on PCB manufacturers, making it essential to choose a partner with a proven track record in producing medical grade PCBs. Key factors to consider include robust quality control measures, comprehensive certification, and a detailed quality management system that aligns with medical industry standards. Experience with advanced electronic components, rigid flex and flexible PCBs, and surface mount technology is also crucial, as is the ability to perform automated optical inspection for defect-free production. Furthermore, familiarity with regulatory requirements from organizations like the Food and Drug Administration (FDA) ensures that every medical device meets the necessary compliance benchmarks. By prioritizing these criteria, medical device manufacturers can confidently select a PCB manufacturer capable of supporting their commitment to quality, safety, and innovation in the medical field.

Our Expertise

At WellCircuits, we bring extensive expertise to the design and manufacturing of high-quality medical PCBs for a diverse range of medical applications. Our team of skilled engineers and technicians is well-versed in medical industry standards, regulatory requirements, and the latest pcb technologies. We specialize in producing rigid, flex, and rigid-flex circuits, as well as multilayer and HDI PCBs, tailored to the unique needs of medical device manufacturers. By implementing robust design, assembly, and testing procedures—including comprehensive quality management systems and advanced flex circuits—we ensure that every medical printed circuit board we deliver meets the highest standards of safety, reliability, and performance. Our dedication to innovation and customer satisfaction has established WellCircuits as a trusted partner in the medical industry, supporting the development of cutting-edge electronic medical devices that improve patient care and outcomes.

Benefits of Partnering with Us

Partnering with WellCircuits offers medical device manufacturers a distinct advantage in the competitive healthcare market. Our extensive experience in producing medical grade PCBs for a wide range of medical devices—including ultrasound machines, patient monitoring systems, and life saving devices—ensures that our clients receive products of the highest quality and reliability. We maintain a detailed quality management system that governs every stage of production, from initial design to final assembly, guaranteeing compliance with all relevant medical industry standards. Our expertise spans rigid, flexible, and rigid flex PCBs, as well as advanced technologies like multilayer PCBs, flex circuits, and high-density interconnects. This allows us to support the development of innovative monitoring systems and other critical medical applications. By choosing WellCircuits, medical device manufacturers benefit from our commitment to quality management, technical excellence, and a collaborative approach that helps bring groundbreaking medical devices to market—improving patient care and saving lives.

Trends in Medical PCBs

The landscape of medical PCB manufacturing is rapidly evolving, shaped by technological advancements and the changing needs of the medical industry. One significant trend is the push toward miniaturization and portability, driving the development of flexible and rigid flex PCBs for compact, wearable, and implantable medical devices. As medical devices become more complex, maintaining signal integrity and managing electromagnetic interference (EMI) have become critical considerations in PCB design. The adoption of advanced manufacturing techniques, such as 3D printing and the use of innovative materials, is enabling the production of more sophisticated and reliable medical printed circuit boards. Quality control remains a top priority, with automated optical inspection and comprehensive testing processes ensuring that every medical PCB meets stringent industry standards. These trends are paving the way for the next generation of high quality medical PCBs, supporting the creation of safer, more effective, and more reliable electronic medical devices for the healthcare sector.

How do I get a price for medical PCBs

We can run DFM/DFA analyses to assist you. We will provide you with an analysis report. It is possible to upload your data safely through our site.

The following details are required to be able to offer you the following quote:

Gerber, ODB++ or IPC-2581

BOM if you require assembly

Quantity

Time to turn

Conclusion

In summary, the medical industry’s reliance on advanced technologies such as medical PCBs is fundamental to improving patient care and saving lives. For medical device manufacturers, selecting a trusted partner for PCB manufacturing is essential to meet the stringent requirements of medical grade applications. WellCircuits stands out as a leader in medical PCB applications, offering expertise in medical device PCB design, assembly, and quality assurance. Our dedication to producing high-quality medical grade PCBs, combined with our deep understanding of regulatory standards and innovative manufacturing processes, makes us the ideal partner for medical device manufacturers. Together, we can develop next-generation medical devices that set new benchmarks for quality, reliability, and patient safety. We look forward to collaborating with you to advance healthcare technology and make a meaningful difference in the lives of patients worldwide.