PCB Circuit Board Design: Minimizing Parasitic Effects of Vias

Printed circuit boards (PCBs) play a crucial role in establishing electrical connections among electronic components. While commonly known as “PCBs,” the term “PCB boards” is redundant and incorrect.

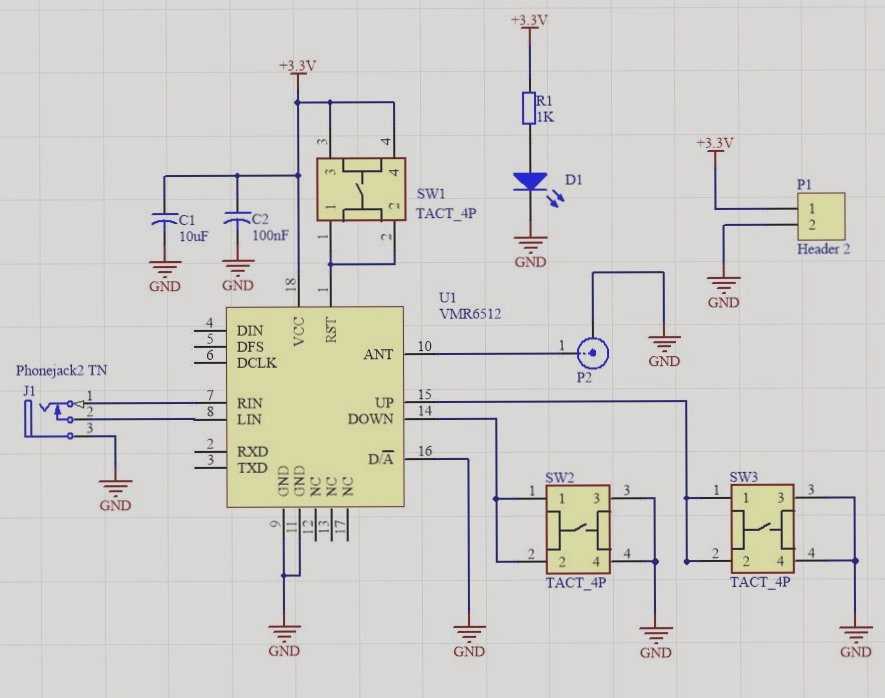

Throughout the PCB design process, even seemingly simple vias can have significant negative impacts on the circuit board’s performance if not carefully planned. Here are some strategies to minimize the adverse effects of parasitic parameters caused by vias in PCB design:

- Place power and ground vias as close to their respective pins as possible to minimize inductance. Keep the lead between the via and the pin short and use thick power and ground traces to reduce impedance.

- Keep signal traces on the PCB direct to minimize unnecessary vias, which introduce parasitic inductance and resistance that can affect signal integrity.

- Consider using a thinner PCB to reduce parasitic parameters like inductance and capacitance associated with vias, leading to improved overall performance.

By implementing these strategies during the via design process, you can effectively mitigate the adverse effects of parasitic parameters and enhance the overall performance of your PCB circuit board.

- When balancing cost and signal integrity, choose an appropriate via hole size. For instance, in the design of 6-10 layer memory module PCBs, 10/20Mil (drilled/pad) vias are recommended. For high-density, small-size boards, 8/18Mil vias may be suitable.

- Position grounded vias near signal vias to provide the shortest return path for the signal. Including multiple redundant ground vias on the PCB can be beneficial.

WellCircuits is an innovative manufacturing company specializing in high-precision PCBs. Our focus includes microwave high-frequency PCBs, high-frequency mixed-pressure boards, ultra-high multi-layer IC testing, 1+ to 6+ HDI, AnyLayer HDI, IC substrates, IC test boards, rigid-flex PCBs, and conventional multi-layer FR4 PCBs. Our products cater to various industries such as Industry 4.0, communications, automotive, medical, aerospace, and the Internet of Things.

If you have any PCB manufacturing requirements, feel free to contact us.