PCB Board Shielding: Enhancing Electromagnetic Compatibility

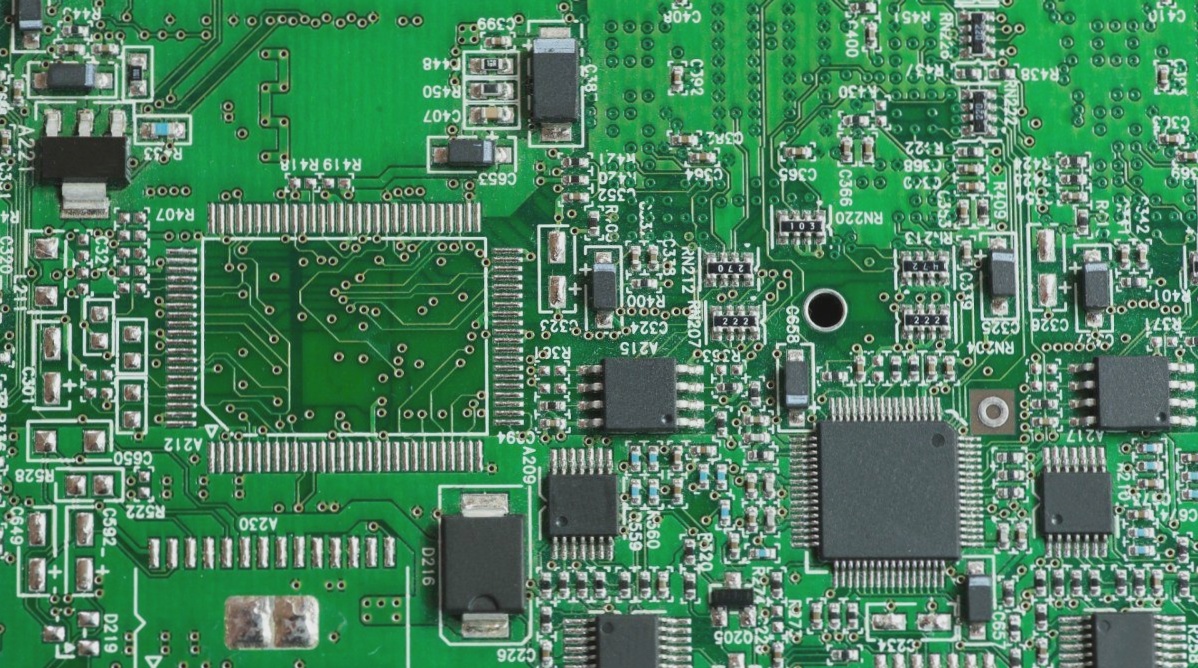

PCB board shielding is a crucial process in electronics manufacturing that involves isolating metal between two spatial areas to control the induction and radiation of electric fields, magnetic fields, and electromagnetic waves. By surrounding interference sources with shielding materials, the spread of interference electromagnetic fields can be prevented, ultimately reducing interference effects.

Key Principles of PCB Board Shielding:

- High-Frequency Interference: Utilize materials with low resistivity to generate eddy currents that counteract external electromagnetic waves.

- Low-Frequency Interference: Use materials with high magnetic permeability to confine magnetic lines of force within the shielding body.

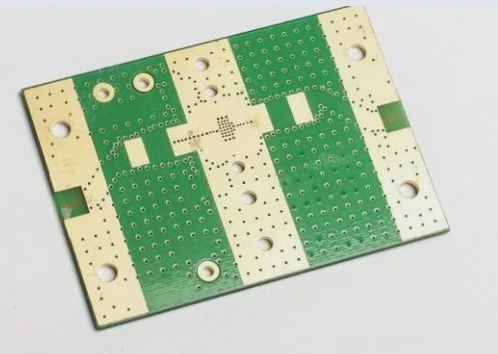

- Multilayer Shielding: Employ different metal materials in multiple layers for effective shielding of both high and low-frequency electromagnetic fields.

Contrary to common misconceptions, successful electromagnetic shielding is not solely achieved by grounding a metal box. The effectiveness of shielding depends on the shield’s conductivity, continuity, and the absence of direct conductors penetrating the shield. Non-conductive gaps in the shield can lead to electromagnetic leakage, which can be addressed by using conductive elastic materials like electromagnetic sealing gaskets.

Electromagnetic Sealing Gaskets:

- Conductive Rubber: Silicone rubber filled with metal particles for elasticity and electrical conductivity.

- Metal Braided Mesh: Tubular strips woven from beryllium copper, Monel, or stainless steel wire to enhance elasticity.

- Finger Reeds: Elastic and conductive reeds made of beryllium copper for effective shielding.

Understanding the principles of electromagnetic shielding and utilizing appropriate materials is essential in ensuring the integrity and reliability of electronic systems.

Multiple Conductive Rubbers for Improved Elasticity

Multiple conductive rubbers consist of two layers: an inner layer of ordinary silicone rubber and an outer layer of conductive rubber. This innovative material addresses the issue of poor elasticity found in traditional conductive rubber, allowing the rubber to exhibit full elasticity. Imagine it as a wire mesh strip with a rubber core, providing enhanced flexibility and conductivity.

Factors to Consider When Choosing Electromagnetic Sealing Gaskets

- Shielding Effectiveness Requirements

- Environmental Sealing Requirements

- Installation Structure Requirements

- Cost Requirements on the PCB Board

When selecting the appropriate type of electromagnetic sealing gasket, it is essential to evaluate these four factors to ensure optimal performance and cost-effectiveness for your PCB board.