PCB Board Means: Understanding the Importance and Process of PCB

Printed Circuit Boards (PCBs) are the spine of contemporary digital devices, imparting each structural assist and electric connectivity for additives. From smartphones and medical gadgets to automobile electronics and business machinery, PCBs play a vital function in ensuring the capability and performance of electronics. However, what exactly does the PCB board method do? This text explores the importance of PCBs, their numerous kinds, design and manufacturing tactics, and destiny tendencies.

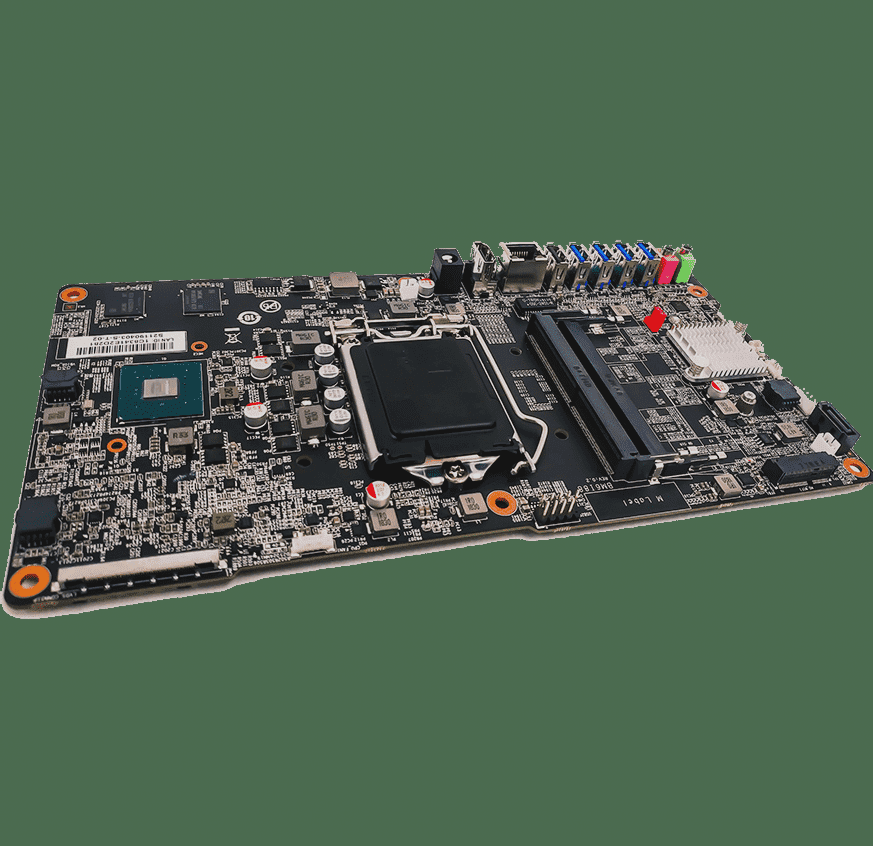

What is a PCB Board?

A PCB board is a non-conductive substrate (consisting of fiberglass or plastic) that helps digital additives and connects them through conductive copper traces. These copper traces shape the electrical pathways that enable additives like diodes, capacitors, resistors, and transistors. relying on the software, PCBs may be unmarried-layer, double-sided, or multi-layered, with every type designed to meet unique complexity and area requirements. PCB is the foundation of modern-day electronics, offering both mechanical guides and electric connections.

Types of PCB Boards

PCBs are available in various paperwork to shape distinctive desires:

- Single-Sided PCB: Components and copper lines are on one side, best for simple programs like toys or basic household home equipment. PCB is simple and cost-effective for basic digital gadgets.

- Double-Sided PCB: components are hooked up on each facet, related via vias (small holes) for more complex devices such as audio devices. PCB has superior capability with additives on both facets.

- Multilayer PCB: more than one layer of copper lines separated with the aid of insulating substances, utilized in compact, high-performance devices like laptops and smartphones. PCB method excessive-density integration for superior electronics.

- Flexible PCB: Crafted from flexible substances, these PCBs can bend and adapt to various shapes, making them best for wearable gadgets and flexible displays. PCB has adaptability and versatility for modern electronics.

- Metal-middle PCB: proposing a metallic base (normally aluminum) for heat dissipation, those PCBs are ideal for excessive-power programs like LED lighting fixtures and power substances. PCB board method green heat control for power-intensive devices.

PCB Design Process Means

Designing a PCB is a complex task that requires precision at every stage:

- Schematic layout: Engineers create a diagram outlining the electric connections using specialised software. PCB board is a nicely-planned electrical format.

- format design: components are placed on the PCB, and copper lines are routed to make certain proper electrical connections. PCB board means an optimized arrangement of additives.

- Layout Rule test (DRC): software program critiques the format for ability troubles, such as hint width or spacing violations, to ensure manufacturability. PCB board method ensuring design accuracy and reliability.

- Gerber document technology: those files comprise all the vital statistics for manufacturing, together with copper lines, drill holes, and solder mask layers.

PCB Manufacturing Process Means

Once the design is approved, the PCB moves to manufacturing:

- Copper Layer Software: Copper is applied to the substrate and etched to form the preferred strains. PCB board method is a precise copper pattern for electrical connections.

- Layer Stacking and Lamination: For multilayer PCBs, copper layers are stacked and bonded with insulating materials through the usage of heat and strain. PCB board method is a multi-layered shape for complex circuits.

- Drilling: Holes are drilled to create vias for electric connections among layers. PCB board manner permitting connections among specific layers.

- Solder mask utility: A defensive layer is implemented to prevent corrosion and solder bridging. PCB board approach protection for the copper traces.

- Silkscreen Printing: Labels and factor markings are printed on the PCB for clean identity. PCB board method clear identification of additives.

- Final Inspection and trying out: The PCB undergoes rigorous testing to ensure high quality and capability. PCB board means reliable electronics.

Importance of PCBs in Electronics

PCBs perform several critical functions in electronic devices:

- Structural help: PCBs provide a strong base for mounting additives. PCB board manner a solid foundation for electronic additives.

- Electric Connectivity: Copper strains create the electrical connections that allow additives to function collectively. PCB board approach green electrical pathways.

- Sign Integrity: The right layout minimizes interference and noise, ensuring dependable signal transmission. PCB board method dependable signal transmission.

- Thermal control: substances and layout assist in depleting warmth, ensuring safe and efficient operation. PCB board approach effective warmness management.

- fee and space efficiency: Compact designs lessen universal product size and value, making electronics greater cheap and efficient. PCB board method optimized area utilization.

Future Trends in PCB Technology

As technology advances, the demand for more efficient, compact, and dependable PCBs grows:

- Higher Density: Smaller devices require PCBs with higher component density without sacrificing performance. PCB board means higher integration for miniaturized devices.

- Flexible and Wearable Electronics: The rise of wearable and bendable devices drives the need for flexible PCBs that can adapt to different shapes. PCB board means innovation in flexible electronics.

- Sustainable Materials: Environmental concerns are leading to the increased use of eco-friendly materials in PCB production. PCB board means eco-friendly electronics.

Conclusion

Better Density: Smaller gadgets require PCBs with better factor density without sacrificing performance. PCB board method better integration for miniaturized devices.

Bendy and Wearable Electronics: The rise of wearable and bendable devices drives the need for flexible PCBs that can adapt to specific shapes. PCB board approach innovation in flexible electronics.

Sustainable materials: Environmental worries are the main reason for the increased use of materials in PCB production. PCB board means electronics.

conclusion

PCBs are crucial in present-day electronics, imparting structural support, electric connectivity, and thermal control. As the generation continues to adapt, PCBs will stay an important factor in improvements starting from scientific devices to customer electronics. Understanding the layout, production, and application of PCBs is essential for absolutely everyone in the electronics enterprise. PCB board means the future of electronics, and as we look in advance, the importance of green PCB layout and production will best grow, riding the development of advanced electronics in all sectors.

WellCircuits offers PCB and PCBA manufacturing services for 1 to 64 layers. For more details, please refer to our PCB manufacturing and PCBA Manufacturing.

If you have any PCB or PCBA RFQ, please send to info@wellcircuits.com