PCB Board Design and Development

Effectively manage the entire hardware development process to ensure that PCB controller hardware meets customer requirements and national standards.

Scope

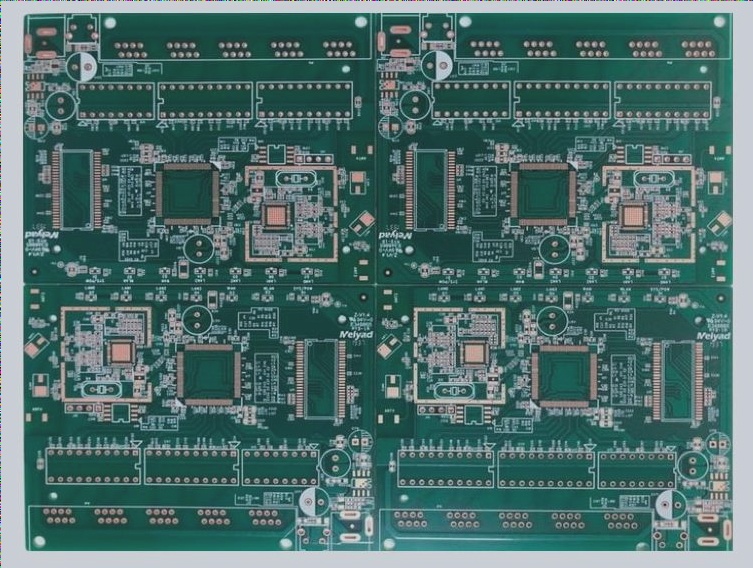

This role involves developing new controller products and improving finalized products.

Duties

- A dedicated development team is formed when control board design and development are required, consisting of product development supervisors, hardware engineers, test engineers, and reliability engineers.

- The product development supervisor oversees project planning and execution, coordinates design processes, and finalizes the design.

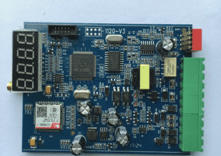

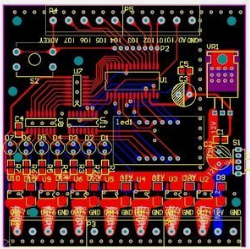

- The hardware engineer handles PCB board layout, hardware circuit design, and debugging.

- The test engineer is responsible for testing hardware circuit prototypes and finished products.

- The reliability engineer designs and verifies hardware circuits for reliability.

Establishment of the Development Team

The PCB product development supervisor forms a hardware development team based on project requirements and creates a “Hardware Product Development Plan.” This plan covers design and development phases, activities, responsible parties, and schedules for each phase.

The plan is regularly updated to reflect design progress, approved by the project team, and reported to superiors.

Methods for PCB Soldering

There are five PCB soldering methods, each with unique advantages:

- Manual Soldering: Ideal for product trials, small batch production, and maintenance, requiring basic tools and simple steps.

- Dip Soldering: Offers high efficiency but requires precision in solder bath temperature control to prevent defects.

- Wave Soldering: Suited for large-scale PCB soldering, controllable in terms of temperature and flux but may lead to solder bridge formation.

- Reflow Soldering: Minimizes thermal stress, ideal for SMD components, but requires advanced tools.

- PCB Contact Welding (Wuxi Welding): Practical for connecting cables to PCB terminals but not suitable for radio PCB welding.