PCB Circuit Board Baking: Pros and Cons

When it comes to PCB circuit board baking, there are advantages and disadvantages to consider.

Advantages of Baking:

- Baking helps in drying the pad moisture, which improves soldering and reduces false soldering and repair rates.

Disadvantages of Baking:

- Baking may change the color of the PCB, affecting its appearance.

Preservation and Baking Methods for PCB Circuit Boards

Proper preservation and baking methods are crucial for maintaining the quality of PCB circuit boards.

Storage and Baking Guidelines:

- For large circuit boards (16 PORT and above), stack up to 30 pieces flat in the oven and cool for at least 10 minutes after baking.

- For small and medium-sized PCBs (8 PORT and below), stack horizontally with up to 40 pieces, and cool naturally after baking.

Factors such as region and production process influence the storage time and baking temperature of PCBs. In regions with high humidity, like southern areas, PCBs should be used within 24 hours of exposure to air to prevent oxidation.

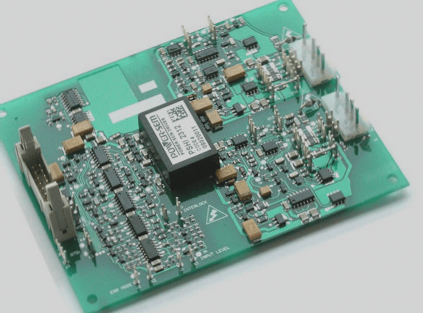

Material Operation Process in PCBA Production

PCBA production facilities follow strict material operation procedures to ensure quality standards are met and materials are used effectively.

Standard Material Operation Process:

- The quality assurance department sets validity periods for raw materials based on standards.

- The warehouse manager prints material labels with essential details like product name, production date, and expiration date.

- Regular checks are conducted on stock materials to monitor expiration dates and re-inspection requirements.

- Materials nearing expiry undergo re-inspection to maintain quality standards.

Effective material management is essential for the smooth operation of PCBA production, ensuring quality and compliance with standards.

Quality Assurance Guidelines for PCB Materials

- Materials passing re-inspection must be approved by the quality assurance department within the specified timeframe.

- If materials are deemed unusable, the purchasing department will negotiate with the supplier for exchange, or the warehouse manager will request the quality assurance department to handle them as non-conforming products.

- Unqualified materials are to be categorized as non-conforming products.

- SMT solder paste should be utilized within 6 months of the production date. Any solder paste exceeding this timeframe will be considered non-conforming and subject to the same procedures as other unqualified items.

- Latest Update: It is crucial for PCB manufacturers to stay updated on industry trends and advancements in PCB material technology. Keeping abreast of the latest innovations can enhance production efficiency and product quality.