PCB Prototypes: Revolutionizing Electronic Solutions

A prototype serves as a crucial sample or test version to explore innovative electronic solutions. The concept of printed circuit boards (PCBs) emerged in the early 20th century, revolutionizing various industries. Today, major companies exhibit a growing demand for PCB prototypes, necessitating diverse manufacturing services, rapid prototype delivery, and strict quality assurance standards.

Meeting Industry Needs

- PCB prototypes play a vital role in leading sectors like aerospace, defense, telecommunications, and healthcare.

- Advanced technologies such as CAD and CAM streamline the prototyping and production processes.

- Expertise in PCB layout and design shines through material fusion and customized component integration.

Enhancing Prototyping Techniques

State-of-the-art tools focus on design analysis, algorithms, and customized technology samples to meet evolving industry demands.

Quality Assurance and Testing

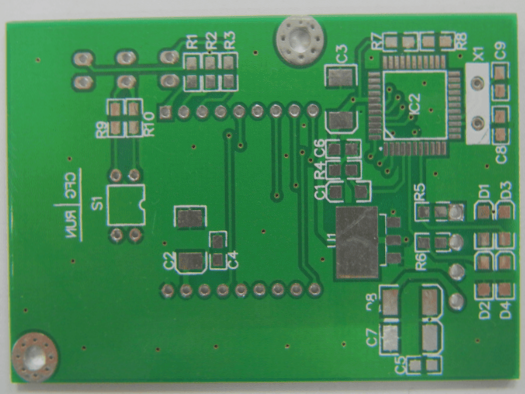

Post-manufacturing, PCBs undergo rigorous quality assessments to ensure durability and reliability. Techniques like thermal analysis and functional testing address complex component issues.

Flexible Prototyping Solutions

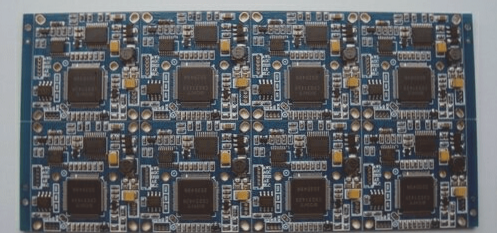

Custom PCB prototyping employs flexible methods and technical expertise to ensure timely project completion within budget constraints. Services range from turnkey assembly to commissioned PCB components.

Efficient Production Management

Cost-effective inventory management and efficient procurement streamline the production of diverse PCB components. This includes manufacturing multi-layer PCBs and testing prototypes for small-batch production, enabling high-speed circuits and multifunctional designs in compact spaces.