Understanding Different Types of PCB Stack-ups

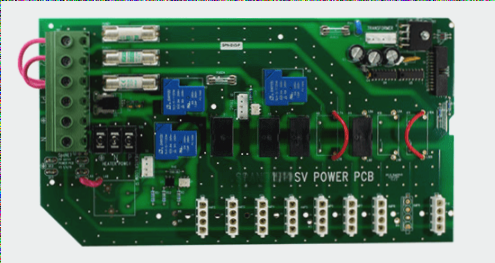

Printed circuit boards (PCBs) come in various types, from single-layer to multi-layer configurations, each serving specific purposes in electronic design.

Single-layer and Double-layer PCBs

Single-layer and double-layer PCBs consist of one or two layers of conductive material on the substrate. These are suitable for simpler electronic designs.

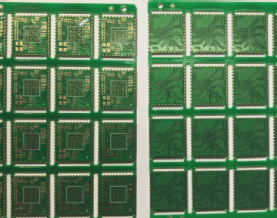

Multi-layer PCBs

For complex designs requiring more routing space and improved signal integrity, multi-layer PCBs are the ideal choice. They combine multiple layers of conductive and insulating materials, creating a sophisticated network of connections.

Prepreg in PCBs

Prepreg, short for pre-impregnated, is a fiberglass cloth infused with uncured epoxy resin. It acts as an insulating layer and adhesive between copper layers or core materials, ensuring a solid bond during PCB manufacturing.

Core of a PCB

The core of a PCB provides mechanical support and rigidity. It consists of laminate material with copper foil layers bonded to a rigid substrate, serving various functions like grounding or signal transmission.

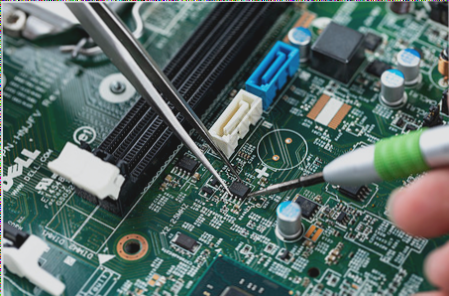

HDI Stack-ups

High-Density Interconnect (HDI) stack-ups utilize micro-vias, blind vias, and buried vias to enhance routing density and electrical performance. The X-N-X structure, such as 1-N-1 or 2-N-2, describes the configuration of HDI layers and core layers in these advanced PCBs.

Explore PCB Stack-ups for Your Design Needs

Whether you’re working on a simple circuit or a complex electronic system, understanding the different PCB stack-ups available can help you choose the right configuration for your project.

- Single-layer and double-layer PCBs for basic designs

- Multi-layer PCBs for advanced routing and signal integrity

- HDI stack-ups for high-density interconnect needs

If you have any inquiries about PCBs or PCBA, don’t hesitate to reach out to us at info@wellcircuits.com.