Military Grade Circuit Boards: The Foundation of Reliable Defense Technology

What Are Military Grade Circuit Boards?

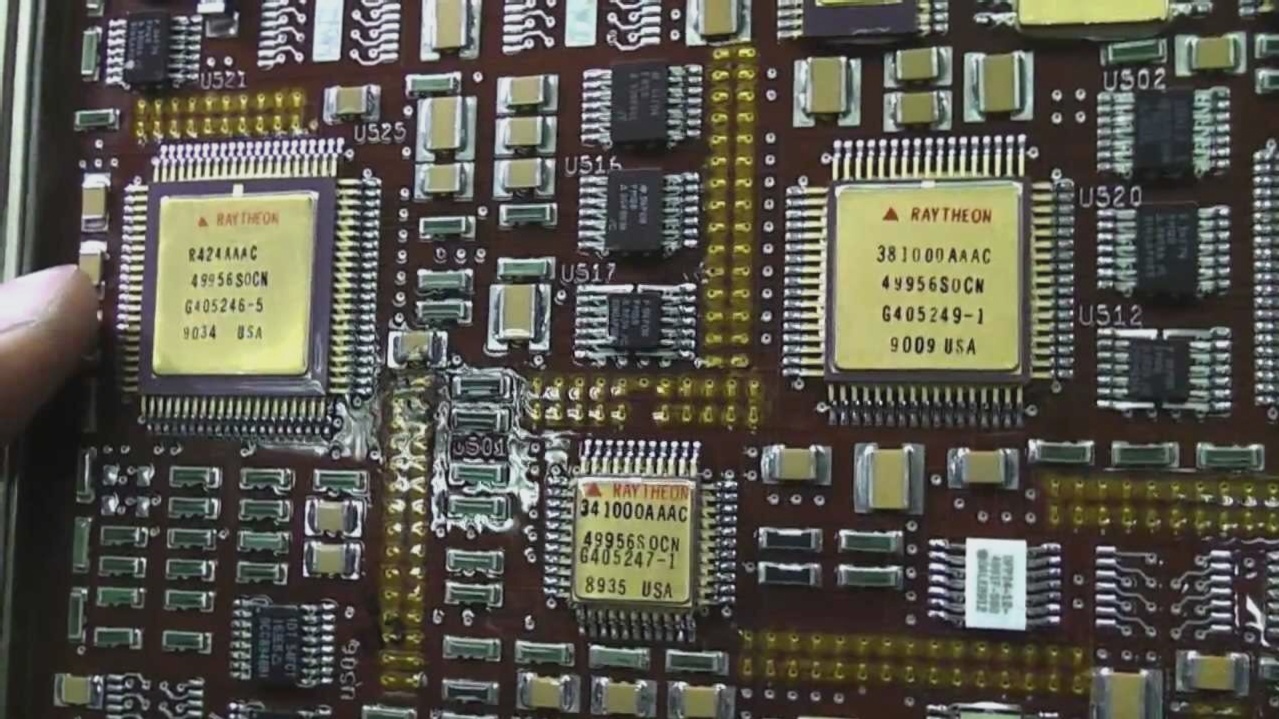

Military grade circuit boards are engineered to meet the rigorous demands of defense applications, offering superior reliability compared to standard printed circuit boards (PCBs). These specialized PCBs must withstand extreme conditions, including high temperatures, chemical exposure, and mechanical stress, ensuring uninterrupted performance in critical military operations.

“Military-grade PCBs adhere to stringent specifications like MIL-PRF-50884 and MIL-PRF-31032, guaranteeing durability in harsh environments.”

Key Differences Between Military and Commercial PCBs

- Tolerance levels: Military PCBs maintain a 1-2% tolerance range vs. undefined commercial standards

- Material composition: High-temperature laminates and copper substrates for thermal stability

- Testing protocols: Rigorous MIL-SPEC qualification processes

- Component density: Multi-layer designs for complex military electronics

Critical Applications of Military Circuit Boards

Modern defense systems rely on high-reliability PCBs for mission-critical operations:

- Satellite communication subsystems

- Unmanned aerial vehicles (UAVs)

- Advanced radar and targeting systems

- Secure military communications equipment

- Weapons guidance systems

These applications demand military-grade PCB manufacturers in China who understand the need for continuous operation without failure, even in extreme combat situations.

Design Considerations for Military Grade PCBs

1. Environmental Resilience

Designers must account for:

- Wide temperature operation ranges (-55°C to 125°C)

- Vibration and shock resistance

- Moisture and chemical protection

2. Signal Integrity Management

How to prevent signal degradation in military PCBs:

- Proper separation of high/low frequency components

- Shielded clock signal routing

- Optimized thermal dissipation pathways

3. Compliance with Military Standards

All designs must conform to:

- MIL-PRF-31032 (Performance Specification for Printed Circuit Boards)

- MIL-PRF-55110 (General Specification for Printed Wiring Boards)

- ITAR regulations for defense-related technology

Selecting the Right Military PCB Manufacturer

How to choose the best PCB manufacturer for defense applications:

- Verify MIL-SPEC certification and ITAR compliance

- Evaluate experience with multi-layer, high-density designs

- Review testing capabilities (environmental stress screening, etc.)

- Assess technical support for military-grade circuit board design

- Confirm secure manufacturing and supply chain processes

Top-tier military PCB manufacturers in China offer:

- Advanced Gerber file verification systems

- Prototyping services with rapid turnaround

- Full documentation and traceability

Key Takeaways for Military PCB Procurement

- Military PCBs require specialized materials and construction techniques

- Design must prioritize reliability over cost considerations

- Compliance with military standards is non-negotiable

- Partner with experienced high-reliability PCB manufacturers

- Continuous technological adaptation is essential for modern defense systems

For organizations requiring military-grade circuit boards for harsh environments, selecting the right manufacturing partner ensures mission-critical reliability and performance.