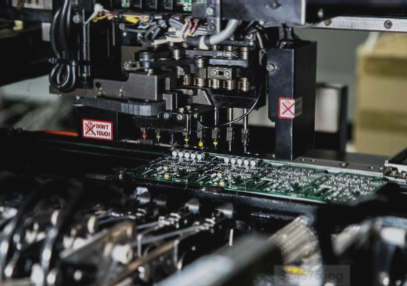

The Importance of Proper Conformal Paint Removal in PCB Assembly

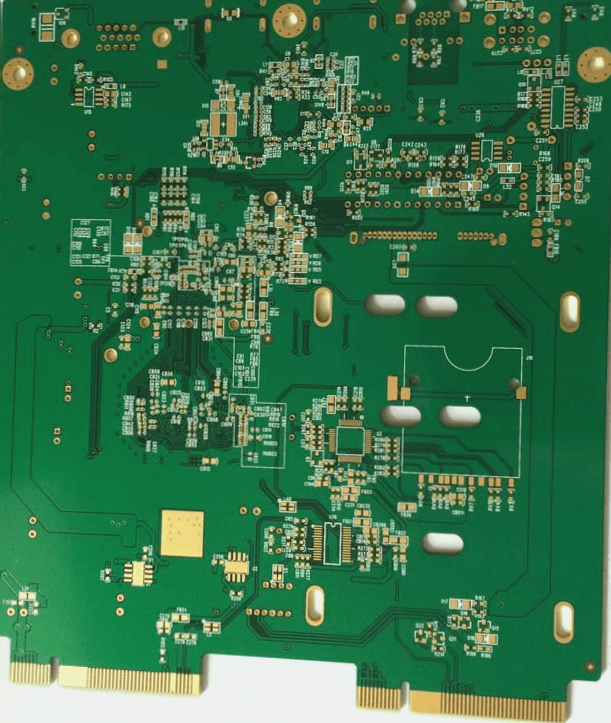

Conformal paint plays a crucial role in protecting electronic assemblies from moisture, dust, chemicals, and high temperatures. However, when it comes time to remove or replace components, proper removal of this coating is essential to prevent damage and ensure the integrity of the PCB.

Methods for Conformal Paint Removal

- Chemical Stripping: Utilizing chemical solvents recommended by the paint manufacturer can effectively soften or dissolve coatings. It is important to follow manufacturer guidelines and test on discarded boards first.

- Mechanical Peeling: Soft coatings can be removed through peeling or scraping with tools like toothpicks or wooden sticks. Care must be taken to avoid damaging components.

- Heat Scraping: Applying heat from a heat gun or soldering iron can soften the coating for gentle removal. This method is suitable for acrylic, epoxy, and silicone coatings.

- Mechanical Scraping: Utilizing abrasives accelerated by inert gas can effectively break down coatings like p-xylene, polyurethane, and epoxy-based materials.

- Laser Ablation: A precision method for targeted removal of conformal paint from PCBs and components.

Considerations for Coating Removal

Choosing the right method and materials for coating removal depends on the type, hardness, and size of the area needing treatment. It is crucial to follow proper procedures to avoid issues such as pad detachment or solder splashing during rework.

Conclusion

Proper conformal paint removal is vital for maintaining the functionality and reliability of electronic assemblies. By selecting the appropriate removal technique and exercising care during the process, potential damage to PCBs and components can be minimized, ensuring the longevity of the final product.

Effective Tri-Proof Paint Removal Techniques for PCBAs

When it comes to removing tri-proof paint from Printed Circuit Board Assemblies (PCBAs), precision is key. One effective method involves using a low-light source in combination with high energy density laser pulses. These pulses gradually remove the coating material without damaging the underlying components. It is essential to use a laser source with the correct energy level and frequency, along with multiple laser channels, to ensure precise removal of the paint while preserving the integrity of the PCBAs.

Benefits of Laser Ablation

- Allows for selective removal of paint

- Precise targeting of areas as small as a few microns

- Effective for removing polyxylene paint

Visual Inspection for Quality Assurance

After the tri-proof paint removal process, it is crucial to visually inspect the PCBA to confirm that the paint has been correctly removed from the designated areas. This inspection ensures that the PCBAs meet the required standards and specifications.

If you have any PCB manufacturing needs or require assistance with tri-proof paint removal, feel free to contact us. Our team of experts is here to help you with all your PCBA requirements.