High-Speed PCB Design and Impedance Control

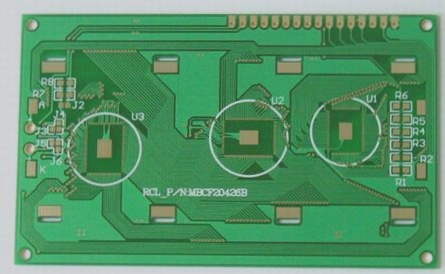

When designing high-speed PCBs, meeting impedance control requirements for transmission lines is crucial. This includes single-ended 50 ohms (±10%) and differential 100Ω (±10%). For more precision, a tolerance of ±5% may be necessary to avoid signal reflection and integrity issues.

Calculating PCB Stack and Impedance

Prior to PCB layout, accurately calculate the PCB stack to achieve the target characteristic impedance, line width, and spacing. Adhering strictly to these dimensions when routing high-speed signal lines ensures compliance with characteristic impedance control specifications.

Addressing Impedance Discrepancies

Even after providing laminated structure and required impedance details to the board manufacturer, discrepancies may arise. Manufacturers need to recalculate and adjust based on their materials and processes, especially when switching manufacturers.

Factors Contributing to Impedance Discrepancies

- Variance in characteristic impedance calculations: Ensure alignment of impedance calculation software with the manufacturer’s software to prevent deviations.

- Coplanar waveguide characteristic impedance: Manufacturers may adjust for process variations, impacting final characteristic impedance accuracy.

Manufacturer’s Role in Impedance Control

Manufacturers play a crucial role in accurately calculating and adjusting impedance values based on personalized PCB designs and production parameters. While ±10% impedance deviation is common, future advancements may allow tighter control.

Ultimately, manufacturers must produce PCBs meeting impedance specifications, balancing costs and performance requirements.

Communication with Board Manufacturer during PCB Layout

During the layout phase, it is crucial to maintain communication with the board manufacturer. This involves specifying the laminated structure, board requirements, and desired characteristic impedance control. Layouts should be created based on the recommended line widths and spacings provided by the manufacturer.

Utilizing Impedance Calculation Software

When performing PCB layout, it is advisable to utilize impedance calculation software for initial theoretical calculations. This helps in assessing whether impedance requirements are approximately met, allowing for some margin for fine-tuning by the board manufacturer. The manufacturer will take care of the remaining impedance control aspects.

Latest Updates:

- Stay updated with the latest PCB design trends and technologies.

- Learn about new materials and techniques for improved PCB performance.

- Explore the impact of 5G technology on PCB design and manufacturing.