Micro-Hole Processing in PCB Printing: Mechanical Drilling

With the advancements in electronic products, PCB printing has evolved to include double-layer and high-precision multi-layer boards. This progression has led to more stringent requirements for circuit board hole processing, with a focus on smaller apertures and hole spacing. Epoxy resin matrix composites are now commonly utilized in plate factories, with hole sizes categorized as small holes (diameter less than 0.6mm) and micro-holes (diameter less than 0.3mm).

Factors Affecting Mechanical Drilling

- Axial Force and Cutting Torque: Two crucial factors to consider during mechanical drilling are axial force and cutting torque. These elements directly impact the quality of the hole and the overall processing efficiency. Operators must be mindful of these factors to minimize defective products and ensure high-quality output.

- Tool Wear: The axial force and torque increase with the feed and cutting layer thickness, leading to rapid tool wear. It is essential for operators to be familiar with the equipment’s performance and replace the drill tool promptly, especially when processing tiny, more expensive holes.

Understanding Axial Force Components

When analyzing axial force, the static component FS influences broadside cutting, while the dynamic component FD primarily affects the main cutting edge. The dynamic component FD significantly impacts surface roughness compared to the static component FS. For holes with a diameter less than 0.4mm, the static component FS decreases sharply with aperture increase, while the dynamic component FD shows a relatively flat trend.

Enhancing Tool Life and Performance

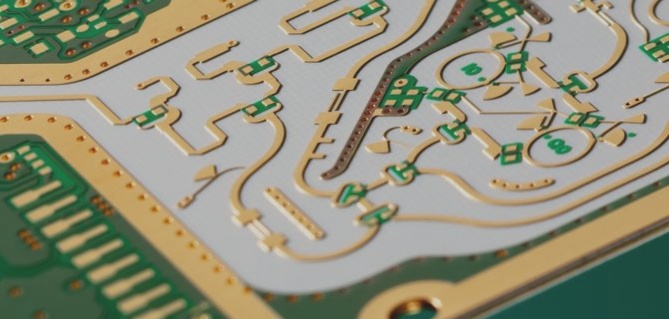

The wear of the PCB drill bit is linked to cutting speed, feed rate, and slot size. The ratio of the bit radius to fiberglass width plays a crucial role in tool longevity. Utilizing a 0.3mm drill tool, for instance, can effectively drill 3000 holes. To address issues like stratification, hole wall damage, dirt, and burring, a 2.5mm pad thickness can be placed below the first layering, providing protection and ensuring proper heat dissipation.

Reducing Burrs and Improving Precision

To minimize burrs, vibration drilling technology and carbide bit drilling can be employed, with adjustments made for tool size and structure to enhance drilling precision and overall performance.