DFMA Design for PCB & PCB Assembly: Optimizing Global Manufacturing Efficiency

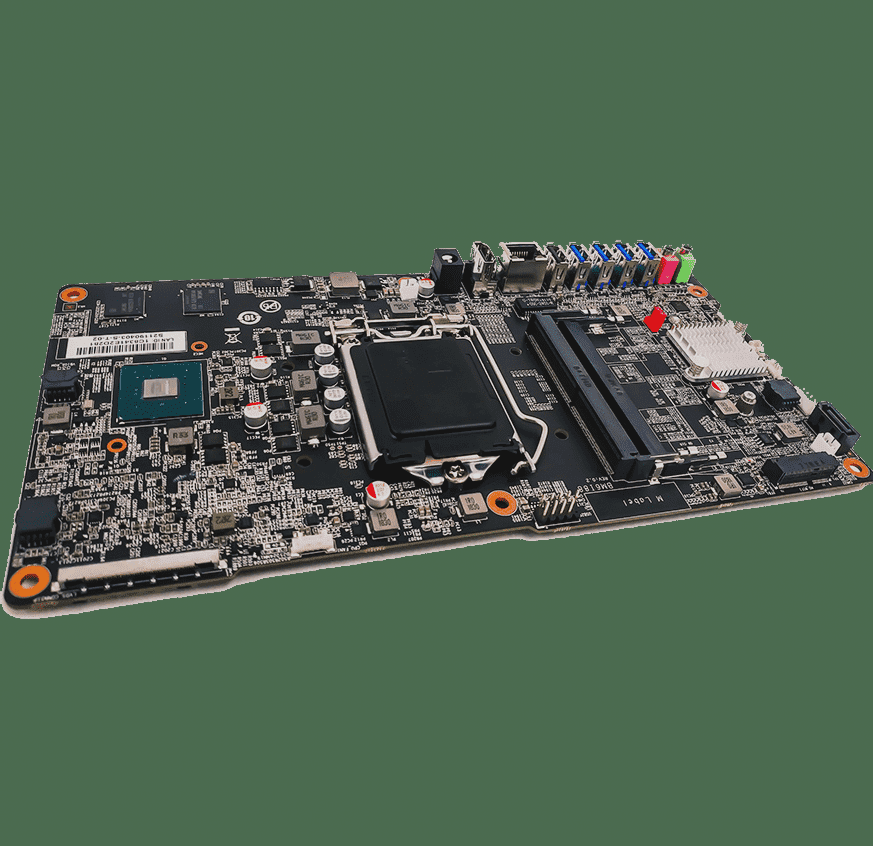

In today’s interconnected world, printed circuit boards (PCBs) power everything from medical devices to transportation systems and entertainment technologies. As demand surges for high-volume PCB production, manufacturers face critical challenges in balancing cost, speed, and quality. This is where Design for Manufacturing and Assembly (DFMA) services deliver transformative solutions for global electronics exporters.

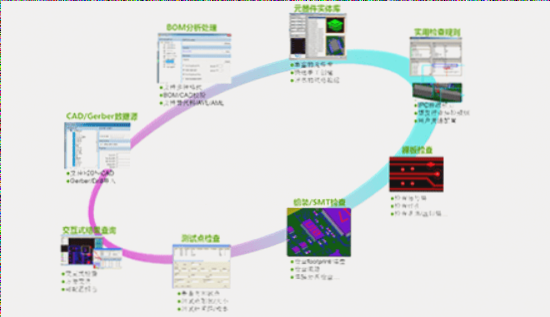

Understanding DFMA: The Dual Methodology for PCB Excellence

DFMA combines two powerful engineering approaches that give PCB manufacturers in China a competitive edge in international markets:

1. Design for Manufacturing (DFM)

- Focuses on production-friendly designs that minimize manufacturing complexity

- Selects optimal materials and processes for cost-effective PCB fabrication

- Reduces waste and improves yield rates for high-volume production runs

2. Design for Assembly (DFA)

- Optimizes component placement for efficient PCB assembly

- Standardizes parts to streamline automated assembly processes

- Minimizes manual intervention in SMT assembly lines

“DFMA isn’t just about cost reduction – it’s a systematic approach to eliminating inefficiencies throughout the entire PCB production lifecycle while maintaining stringent quality standards.”

Core Principles of DFMA for PCB Manufacturing

Successful implementation of DFMA requires adherence to these fundamental principles:

Strategic Production Planning

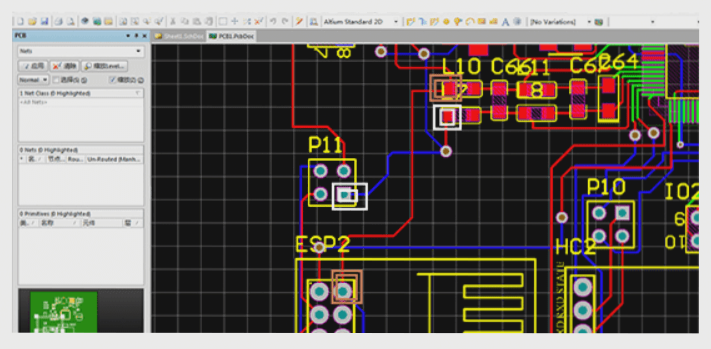

Our PCB design experts begin with comprehensive analysis of your schematics, identifying opportunities to:

- Simplify circuit layouts for easier fabrication

- Optimize panel utilization to maximize material yield

- Standardize design elements across product lines

Material Optimization

We leverage our global supply chain networks to:

- Source high-quality materials at competitive prices

- Implement intelligent nesting to reduce copper waste

- Select components with optimal availability and lead times

Process Streamlining

Our China-based manufacturing facilities employ:

- Lean manufacturing principles to eliminate bottlenecks

- Automated workflows for consistent quality output

- Ergonomic workstation layouts to minimize handling time

Standardization Protocols

We maintain rigorous standards across:

- Drilling and routing operations

- Solder paste application processes

- Inspection and testing procedures

Why Global Buyers Choose DFMA-Optimized PCB Solutions

Implementing DFMA delivers measurable benefits for international electronics companies:

Enhanced Quality Control

- Automated optical inspection (AOI) at multiple stages

- Statistical process control for consistent output

- Reduced human error in high-precision PCB assembly

Accelerated Production Cycles

- 30-50% faster turnaround times versus conventional methods

- Just-in-time material flow systems

- Parallel processing capabilities for urgent PCB orders

Cost Efficiency

- 15-30% reduction in total production costs

- Lower material waste through optimized panel utilization

- Reduced rework and scrap rates

Reliability & Compliance

- Built-in testing at every production stage

- Compliance with international quality standards (IPC, ISO)

- Traceability systems for quality assurance documentation

DFMA in Action: Real-World Applications

Our DFMA services have transformed production for:

- Automotive electronics manufacturers requiring high-reliability PCBs

- Medical device companies needing precision-controlled fabrication

- Industrial equipment producers demanding cost-optimized volume production

- Consumer electronics brands competing in fast-moving global markets

Partnering for Global Success

As a leading PCB manufacturer in China, we combine DFMA expertise with:

- State-of-the-art production facilities

- Multilingual technical support teams

- Global logistics capabilities for seamless international shipments

Whether you need prototype PCB assembly or high-volume production runs, our DFMA-optimized processes ensure you receive:

- Competitively priced, high-quality PCBs

- Reliable on-time delivery worldwide

- Technical support throughout product lifecycle