Immersion Gold (ENIG) and Gold Finger in PCBs

Immersion gold (ENIG) is a crucial surface treatment for PCBs. The process involves plating a layer of gold onto the copper to prevent oxidation, ensuring optimal conductivity and performance of the circuit board.

Gold Finger: The Key to Memory Module Connectivity

Gold fingers, also known as brass contacts, play a vital role in transmitting signals between components on a memory module. With a gold-plated surface and a finger-like structure, gold fingers provide stable deposition, excellent brightness, and superior weldability.

Choosing the Right Surface Treatment

When deciding between gold sinking + gold-plated fingers or tin plating + gold-plated finger processes, consider factors like board welding, circuit performance, pad attachment, and cost efficiency. Tailoring the surface treatment to the board’s specific requirements is essential for optimal functionality and durability.

Addressing Tin Plating Issues

If a gold-plated PCB cannot be tin-plated, investigate potential causes such as oxidation, temperature variations, solder paste quality, or battery material. Implement corrective measures like adjusting plating parameters, monitoring anode consumption, and optimizing anode distribution to ensure successful tin plating.

Categories of PCB Gold Fingers

- Maintain strict control over storage time and environmental conditions during storage, and follow proper manufacturing procedures.

- Use a solvent to clean any debris, and if silicone oil is present, wash it with a specialized cleaning solvent.

- During PCB soldering, control the temperature between 55-80 ℃ and ensure sufficient preheating time.

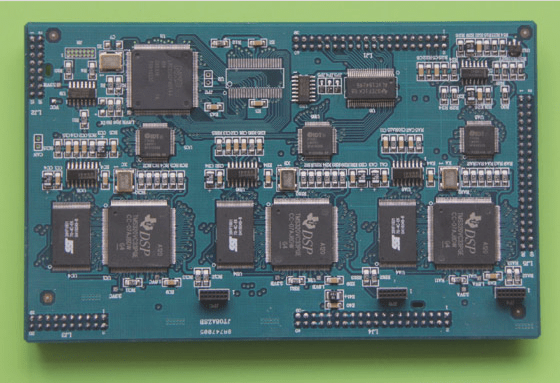

Definition and Function of a Golden Finger

A golden finger is utilized to insert one end of the PCB circuit board into a connector card slot, facilitating the connection between the insertion pin of the connector and the pad or copper skin on the circuit board. This alignment ensures a proper connection. Typically, a nickel gold plate is plated onto the pad or copper skin to improve conductivity and resistance to oxidation and wear.

Classification and Recognition Characteristics of Golden Fingers

Golden fingers can be categorized as ordinary gold fingers (flat fingers), segmented gold fingers (intermittent gold fingers), and long and short gold fingers (uneven gold fingers).

- Ordinary gold fingers are neatly arranged on the board’s edge, with rectangular pads of the same length and width.

- Segmented gold fingers consist of rectangular pads with varying lengths on the edge of the board, featuring a disconnection in the front section.

- Long and short gold fingers showcase rectangular pads of different lengths at the edge of the PCB board.