Designing a High-Quality DC Power Supply PCB

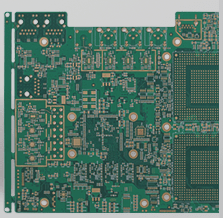

Designing a DC power supply PCB involves translating a schematic into a physical board. While the theory may seem straightforward, practical implementation can be challenging. Expertise is crucial in handling high-frequency and weak signals for successful PCB production.

Key Steps in DC Power Supply PCB Design

- Establish Clear Design Goals: Define the purpose of the PCB, whether for standard, high-frequency, small-signal processing, or a combination. Attention to layout, routing, and signal trace optimization is vital.

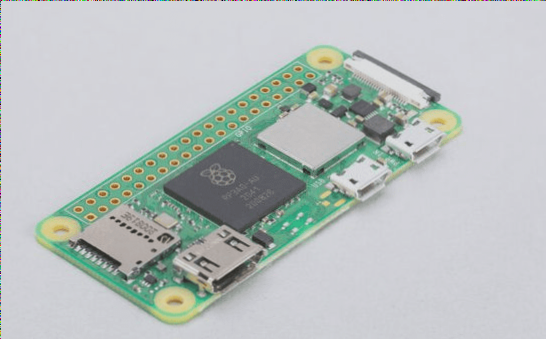

- Coating and Assembly: Three-coat PCB coating post-assembly aids in component protection and repair. Repairing individual components is preferred over replacing the entire board.

- Maintenance and Replacement: Easy cleaning and repairability are essential. Choose appropriate protective coatings like silicone resin or acrylic for efficient maintenance.

Benefits of Silicone and Acrylic Three-Proof Paint

Silicone three-proof paint offers low odor, weather resistance, and versatility across industries. On the other hand, acrylic paint cures quickly, resists moisture and high temperatures, suitable for various electronic applications.

Choosing the Right Coating

While silicone paint excels in harsh environments, acrylic paint is ideal for applications requiring quick curing and high resistance. Consider the environment and maintenance needs when selecting a protective coating.