Enhancing PCB Protection Against Environmental Factors

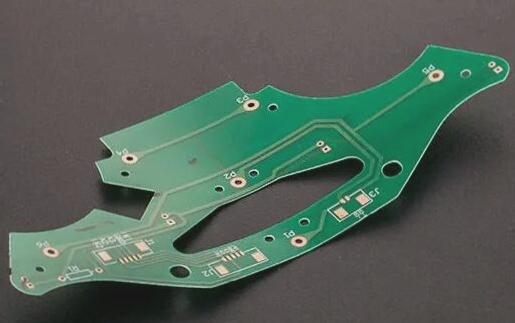

In today’s age of technological advancement, electronic devices play a crucial role in the operations of manufacturing units, OEMs, SMEs, large corporations, and giant enterprises. The slightest electronic malfunction can lead to substantial economic losses. Printed circuit boards (PCBs) are vital components in all devices, making maintenance and protection of PCBs essential for efficient operations.

Common Causes of PCB Failures

One prevalent cause of circuit board failures is moisture exposure, especially in external environments. Various industries, such as chemical, automotive, aerospace, and telecommunications, face challenges due to moisture-related issues. To prevent PCB malfunctions caused by moisture invasion, consider the following:

- Equip the PCB with a tight enclosure and a robust sealing system to prevent moisture ingress.

- Utilize desiccants inside the enclosure to absorb moisture effectively.

- Apply a suitable conformal coating on the PCB to enhance moisture resistance and protection against external elements.

- Use protective materials like silicone or epoxy to shield the entire PCB from external factors.

By implementing these protective measures, you can significantly reduce the risk of PCB failures in humid or challenging environments. Consult with a professional PCB manufacturer to determine the best protection strategies for your specific PCB requirements.

Addressing Thermal Challenges

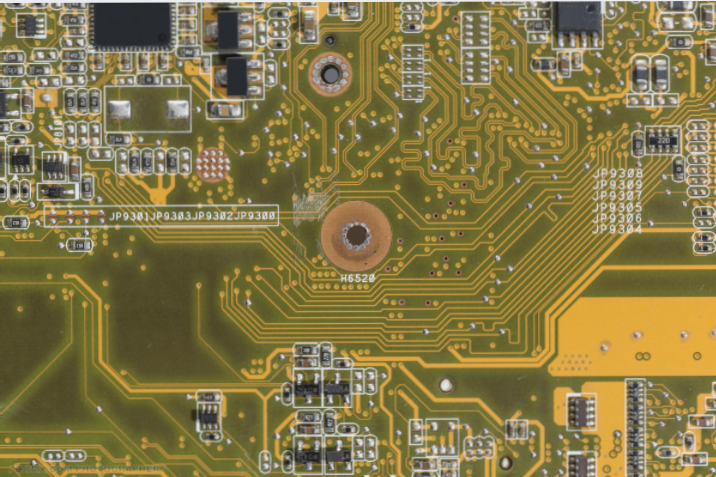

Aside from moisture, thermal conditions can also lead to PCB failures in outdoor settings. It is crucial to consider temperature control and thermal expansion issues when designing PCB layouts for outdoor applications. Utilize PCB manufacturing technologies that offer solutions for thermal management and high thermal conductivity to ensure the longevity and reliability of your PCBs.

By following best practices for PCB protection against environmental factors, you can enhance the durability and performance of your electronic devices in various industrial settings.

Preventing PCB Failure in Harsh Environments

In many instances, outdoor electrical equipment and devices housed in control enclosures may experience malfunctions or shutdowns due to thermal issues. Fluctuations caused by extreme temperatures, whether excessively high or low, can result in the need for PCB rework or repair. Overheating of electrical equipment or prolonged use of internal electronic components poses a significant thermal challenge in outdoor settings.

On the other hand, severe hot climates can introduce various elements such as solvents, oils, corrosive substances, sugary residues, saltwater, fibers, or dusty environments. To mitigate the risk of PCB failure due to thermal concerns, it is essential to implement the following strategies:

- Regularly assess and balance the internal heat of the circuit board.

- Select the appropriate IP rating considering the harsh environmental conditions.

- Identify an effective heat dissipation solution and installation method based on the climate response of the installation location.

- Employ early detection techniques for condensation to prevent damage to PCB components.

- Consistently monitor and measure humidity levels (dry, humid, or very humid) and air temperature (maximum average temperature).

- Conduct comprehensive inspections of the installation site to comprehend the specific challenges faced by the electrical equipment.

- Regularly analyze and evaluate the air quality at the installation site.