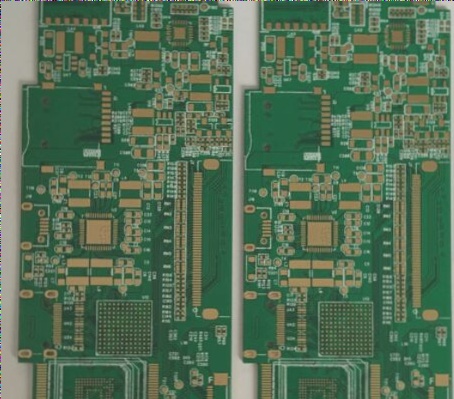

Methods to Correct PCB Copy Board Deformation

-

Splicing Method

For PCB copy boards with simple lines and irregular deformations, cut and resplice the negative film according to drill test board hole positions. Check connection correctness after splicing.

-

Printed Circuit Board Copy Board for Changing Hole Positions

Use a digital programming instrument to adjust hole positions based on size and deformation. Align the drilling test board with the deformed negative for accurate corrections.

-

Pad Overlap Method

Enlarge holes on the test board into pads to overlap and deform the circuit piece, ensuring ring width requirements. Suitable for films with line widths and spacings over 0.30 mm.

-

Photography

Enlarging or reducing deformed graphics using a camera may result in film loss. Precise focus is crucial to avoid line deformation. Applicable for silver salt films.

-

Hanging Method

Allow negative film to stabilize by hanging in working environment conditions for 4-8 hours before copying. Helps prevent deformation and should be done in a ventilated, dark environment.

Deformation of PCB copy boards can negatively impact quality and performance if not corrected properly. Directly discarding deformed boards leads to additional costs and waste. Implementing the right correction methods is crucial to ensure the integrity and functionality of the PCB copy board.