Repairing Damaged Printed Circuit Boards: A Comprehensive Guide

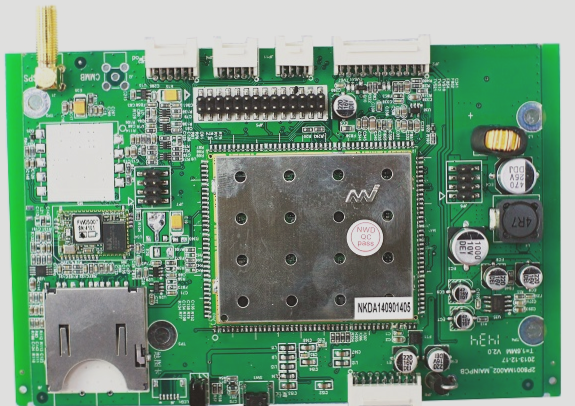

- Physical damage to PCB components often results from mishandling during assembly work.

- Can laminated material damaged during handling be effectively repaired?

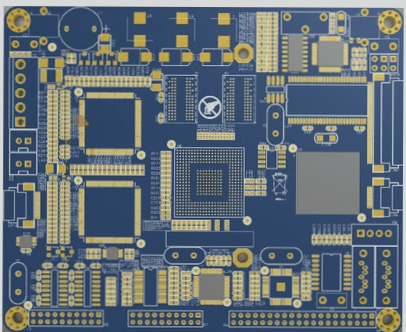

- Understanding the industry standard “IPC-A-610” for evaluating electronic component acceptability.

- Identifying defects in components based on minimum electrical clearance requirements.

- Dealing with damaged corners and exposed base metal as classified defects.

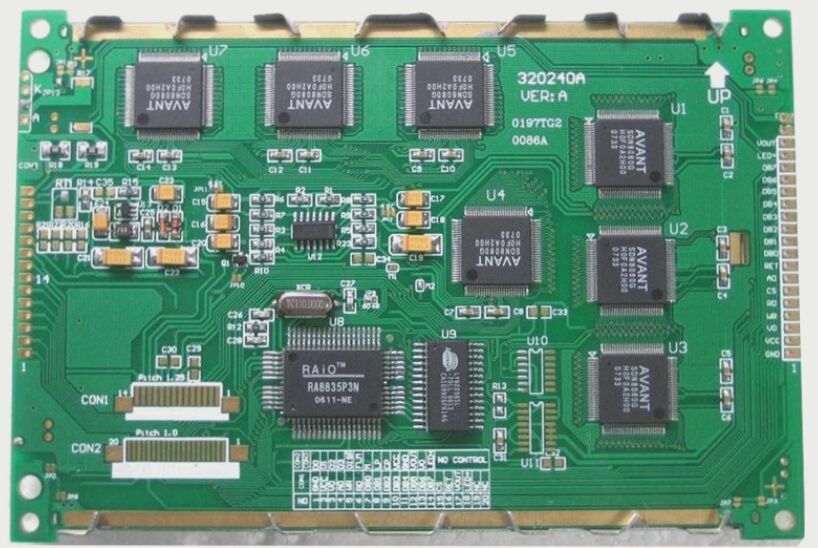

According to the “IPC-A-610” standard, corner damage exceeding half the distance of 2.5 mm from the PCB edge to the nearest conductor is considered a defect. When a damaged corner is confirmed as a defect, various disposal options can be considered, including repairing the PCB with epoxy resin or corner implants.

Inspecting components for additional damage post-impact, especially fragile solder alloys, torn pads or traces near corners, cracked coatings, and damage to solder mask and components is crucial. The “IPC-7721” guide details methods like epoxy resin repair and corner implants for repairing damaged laminates and broken corners on PCBs.

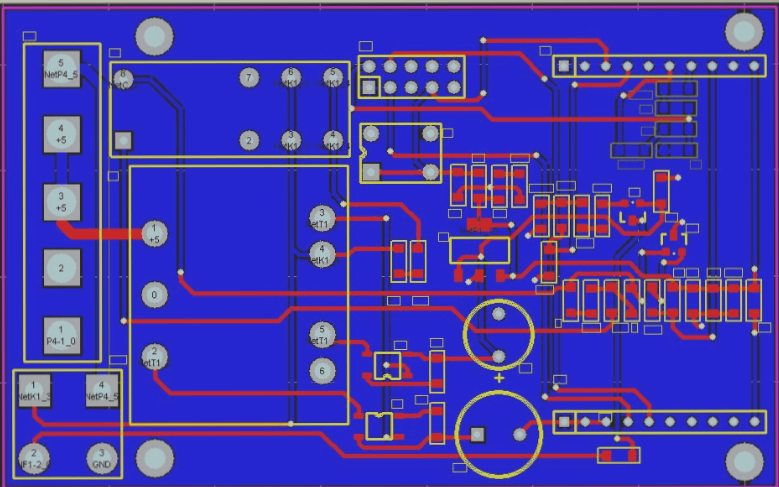

The epoxy method is commonly used for repairing assembled rigid PCBs. Assessing damage extent, cleaning the repair area, and checking inner circuit wiring are essential steps. Grinding burrs, cutting damaged corners, and obtaining necessary skills for internal circuit repairs are part of the repair process. Utilizing small tools and a plastic box for convenience during repairs is recommended.

Repairing Damaged PCB Corners with Epoxy Resin

To repair damaged corners on a circuit board, start by mixing the adhesive resin and hardener as per the PCB manufacturer’s instructions. Then, pour the epoxy resin mixture into a modified container, aligning it with the damaged area. Ensure the surface is smooth and let the epoxy resin cure according to guidelines.

After curing, use emery cloth and water to wet sand the adhesive. You may need to add more epoxy or colorant to match the repaired corners with the original design. Clean and re-inspect the maintenance area to meet acceptable standards.

By following this epoxy resin method, you can effectively fix damaged corners on a PCB, saving it from being discarded.